A prefabricated concrete wall panel and the wall panel structure system with concealed frame

A prefabricated concrete and dark frame technology, applied in construction, building materials, building structure, etc., can solve the problems of too many on-site assembly nodes, poor safety performance, no operability, etc., to achieve effective and reliable connection, solve the Poor seismic performance and overall performance, and the effect of improving integrity and seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

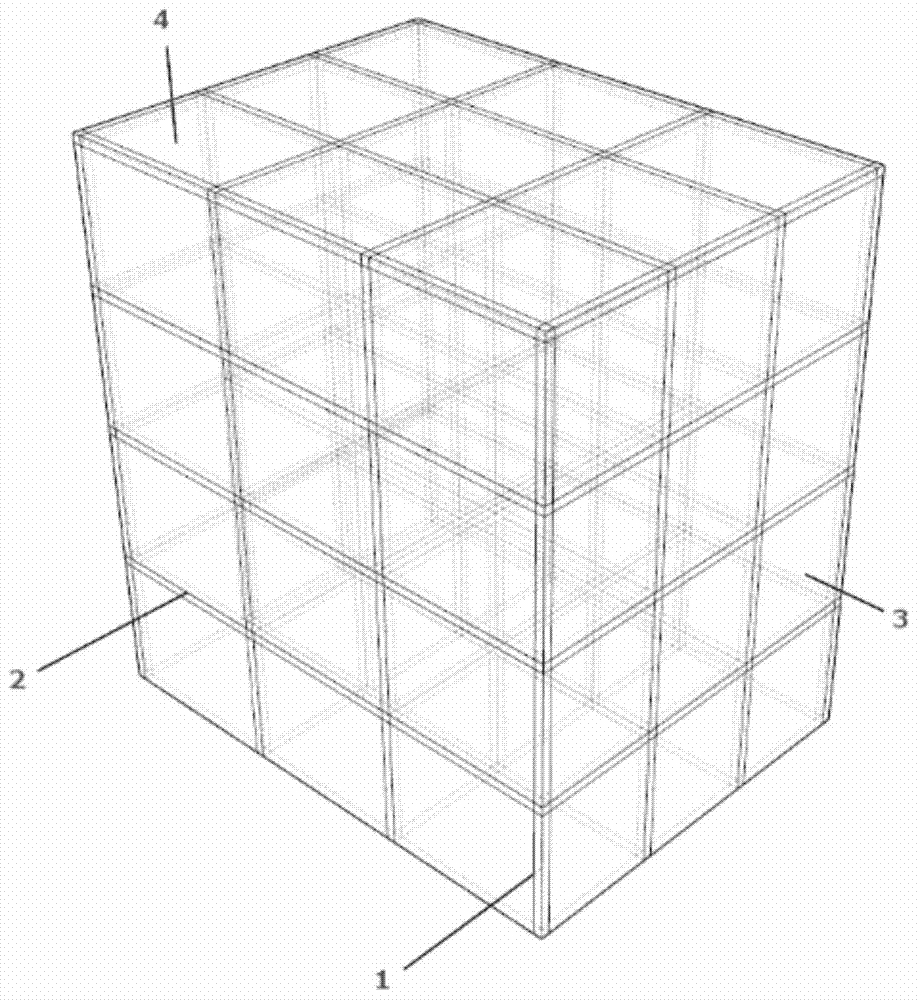

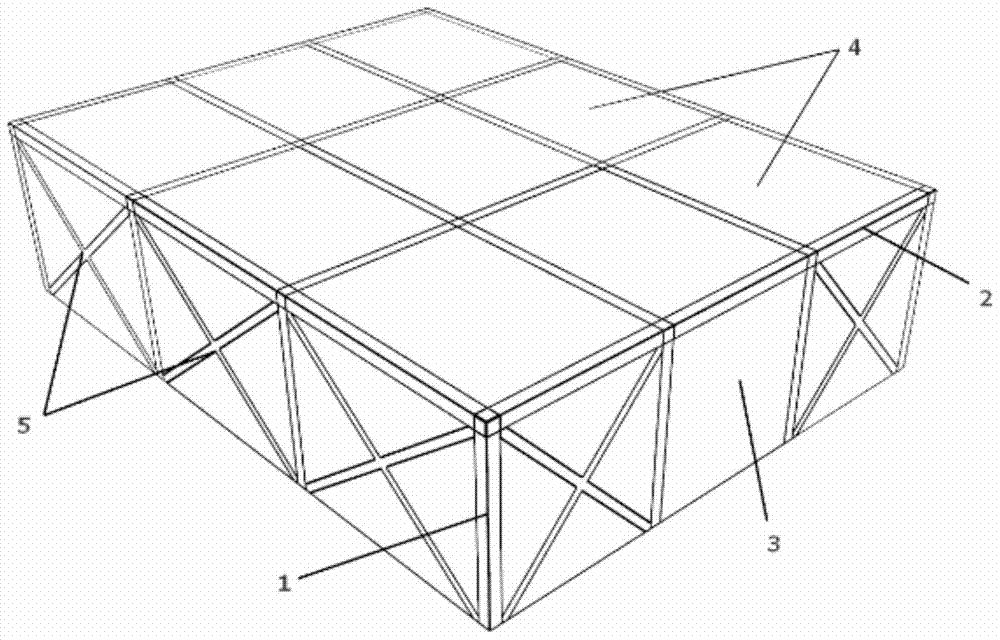

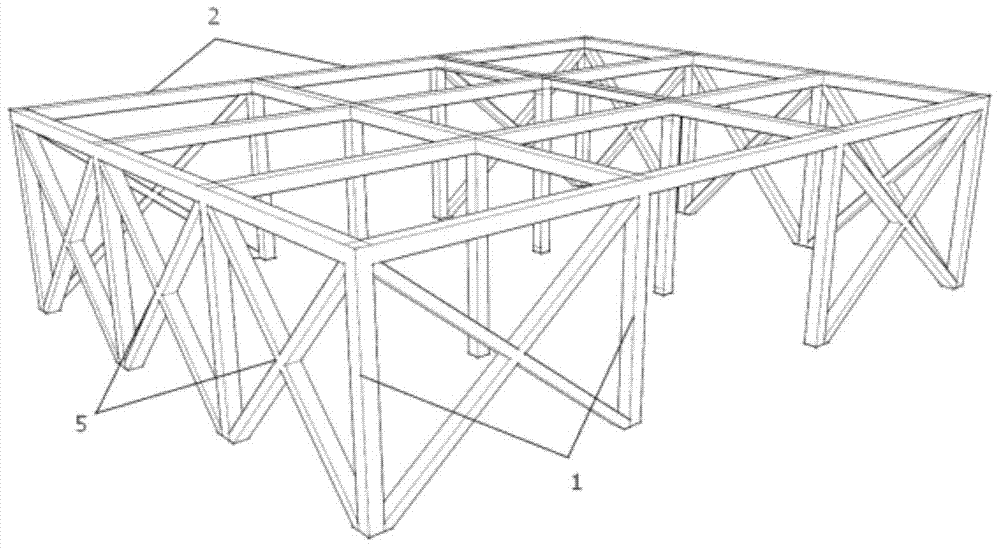

[0039] see Figure 1 to Figure 3 , the wall panel structure system with concealed frame in the illustration is built by wall panels 3 and floor slabs 4, and a concealed frame structure is formed inside. The concealed frame structure includes concealed frame columns 1, concealed frame beams 2 and concealed frame supports 5. The dark frame column 1 is the main body of the vertical support of the structural system, and is located on the side where the wall panels are vertically connected to the wall panels. 1 are connected as a whole, and the skeleton of the dark frame support 5 is arranged along the diagonal of the wall panel, and is connected with the connection nodes of the dark frame column 1 and the dark frame beam 2 to form an integral dark frame structure. The wall panel structure system is installed on the building foundation of natural foundation, independent foundation under column or pile foundation.

[0040] Such as Figure 4 and Figure 5 As shown, the figure is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com