Assembly type concrete integrated bench

A concrete and prefabricated technology, which is applied to chairs, other seating furniture, stools, etc., can solve the problems of adverse effects on the environment and human health, consumption of wood and metal materials, and time-consuming production processes, etc., to achieve long product life, The effect of strong environmental adaptability and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

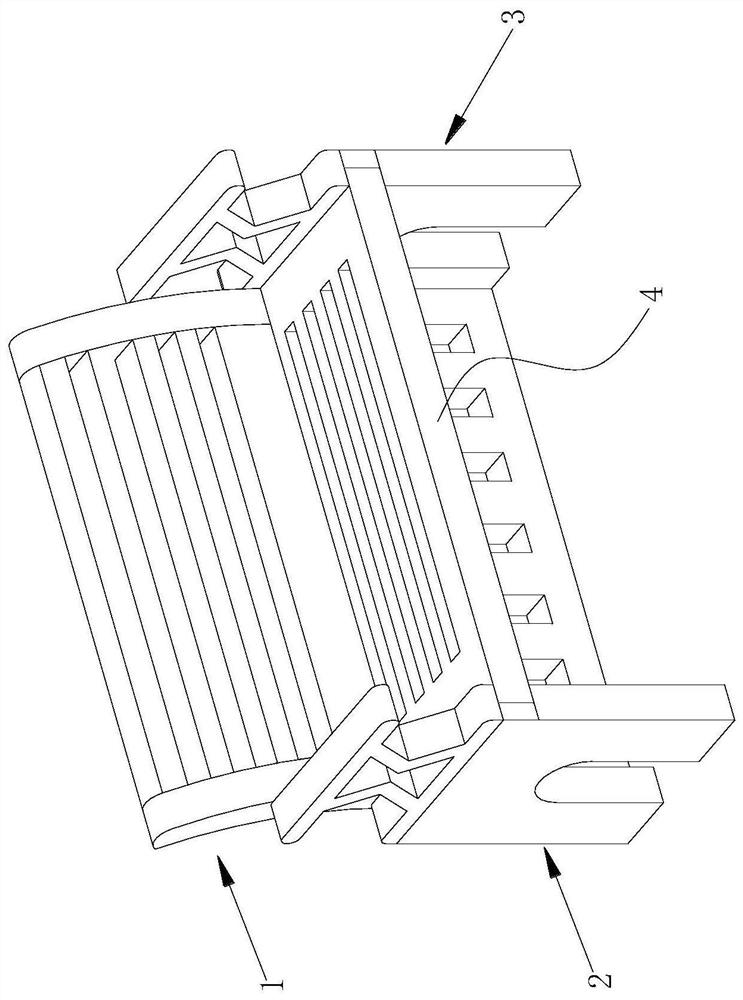

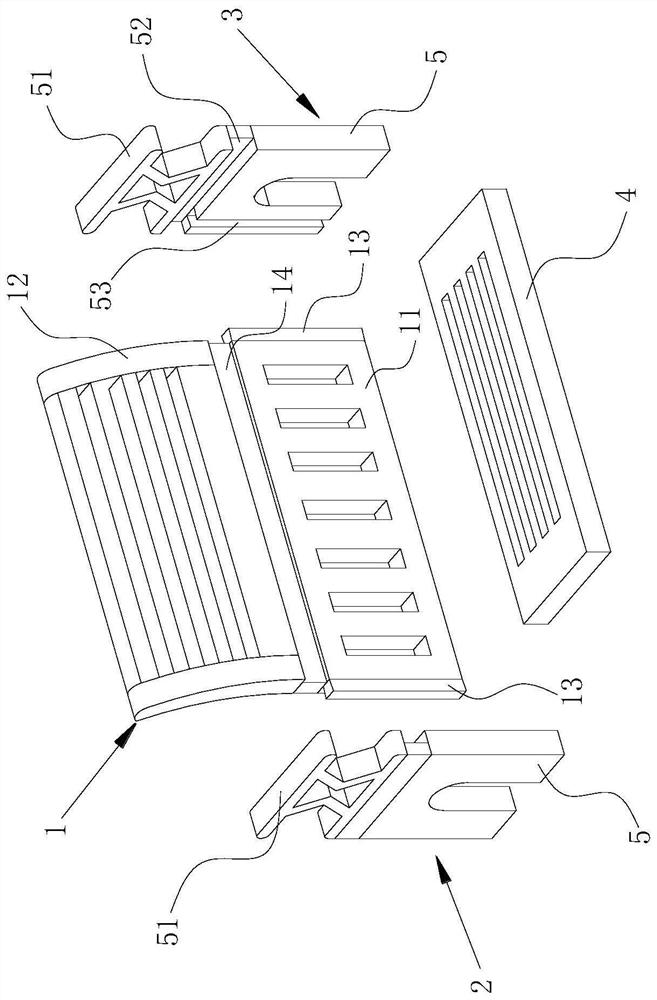

[0021] see figure 1 , figure 2 , a prefabricated concrete integrated bench, including a back support assembly 1, a left support assembly 2, a right support assembly 3 and a seat surface assembly 4 all prefabricated by concrete;

[0022] The back support assembly 1 includes a rear support plate 11 arranged vertically and whose length direction is left and right. A chair back 12 is provided on the upper side of the rear support plate 11. A length direction It is a long strip-shaped first groove 14 running left and right. The length direction of the first groove 14 runs through the left and right ends of the rear support plate 11. There is a vertically arranged strip-shaped tenon on the left and right sides of the rear support plate 11. 13. Let the side of the two long tenons 13 close to each other in the left and right direction be the inside, and the side away from them be the outside. The cross-sections of the two long tenons 13 are both isosceles trapezoids with wide outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com