A prefabricated reinforced concrete fire partition structure and its construction method in stairwell

A reinforced concrete and precast concrete technology, applied in fire prevention, building structure, building components, etc., can solve the problems of easy cracking and high cost of fireproof partitions, and achieve the effect of convenient production, reduction of steel and concrete consumption, and integration of decoration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

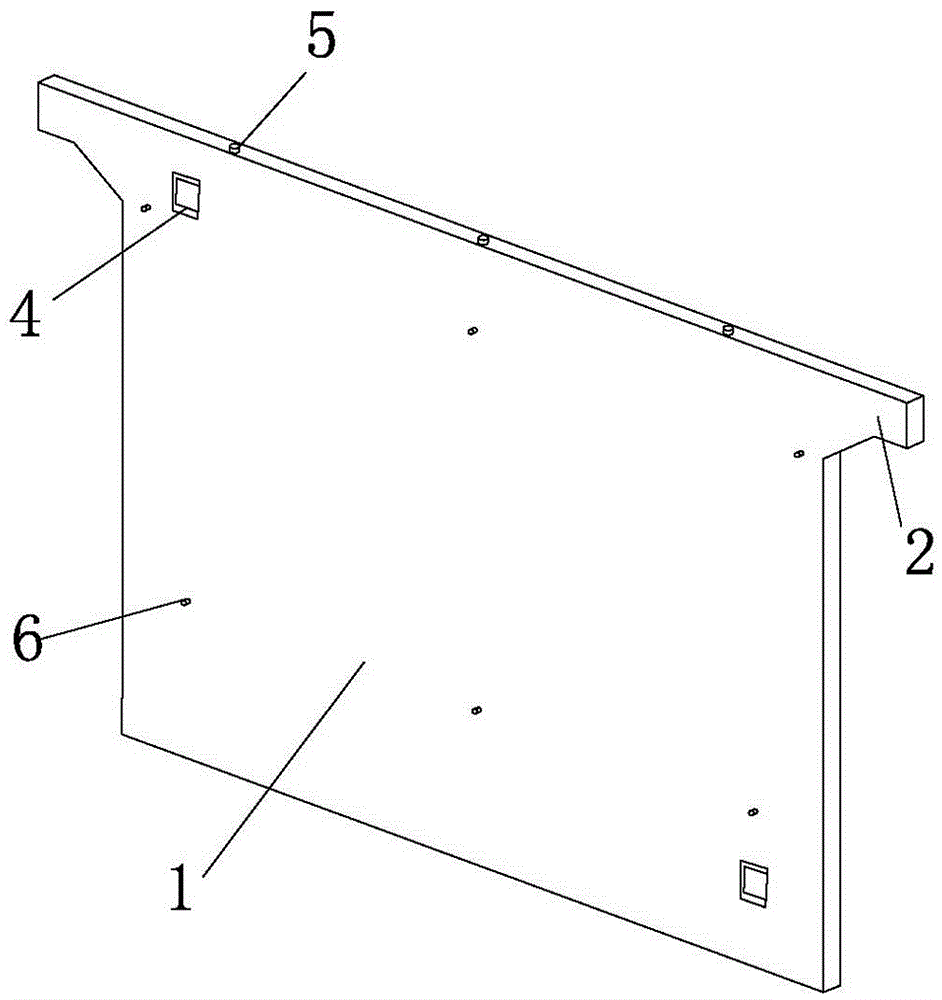

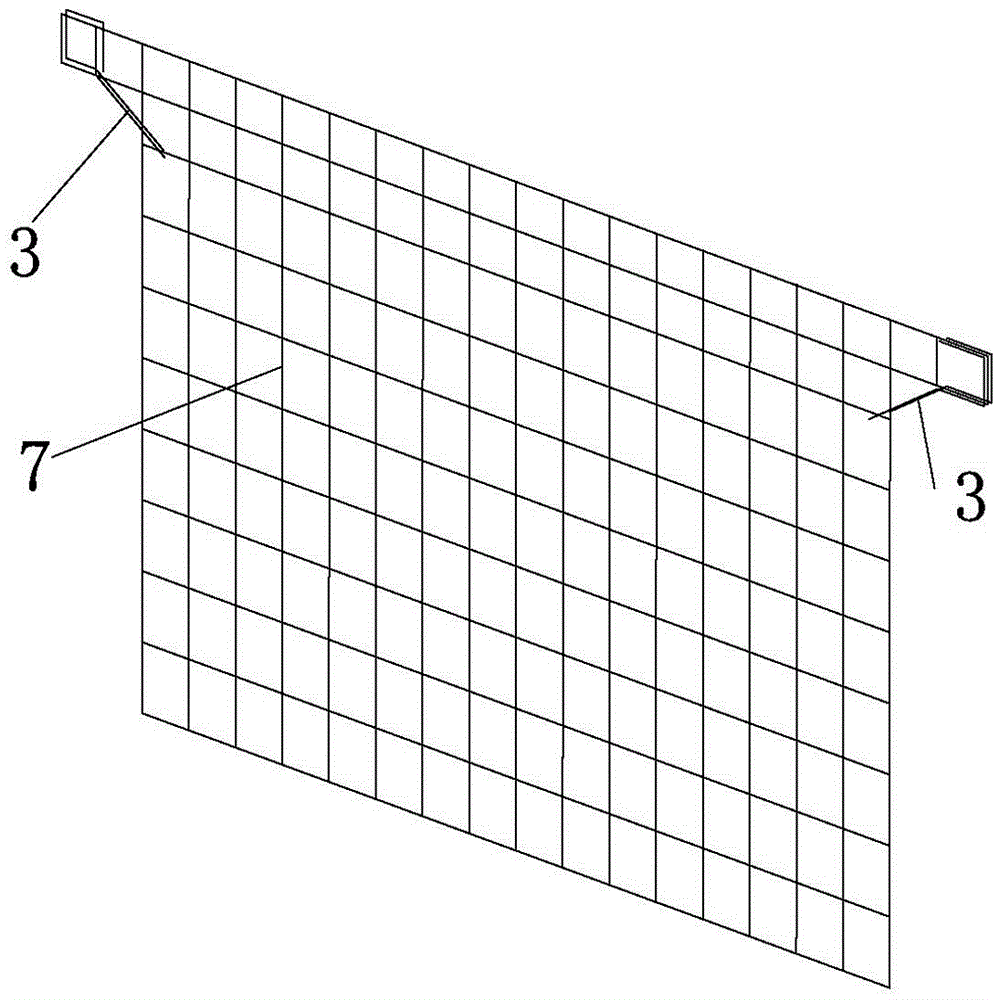

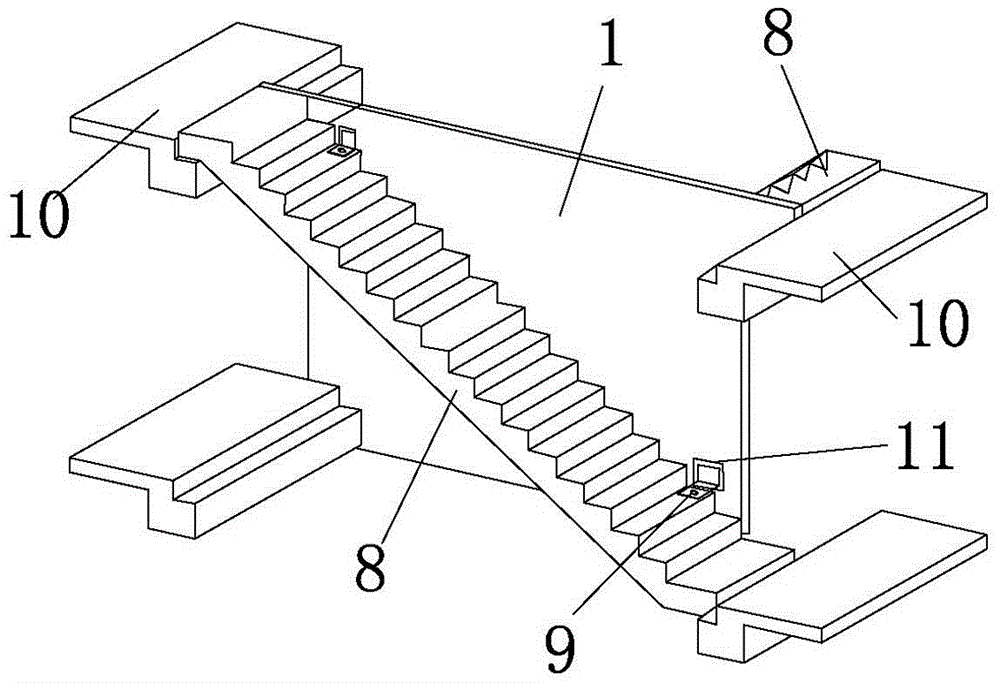

[0028] Such as Figure 1-Figure 3 As shown, a prefabricated reinforced concrete fireproof partition structure in the stairwell is composed of a prefabricated reinforced concrete fireproof partition 1, a prefabricated concrete staircase 8, a stairwell rest platform beam 10 and a connecting piece 11; the upper part of the prefabricated reinforced concrete fireproof partition 1 There are clapboard lugs 2 on the side, and a layer of lug steel bars 3 are laid inside the clapboard lugs 2. The prefabricated reinforced concrete fireproof clapboard 1 is hung on the top surface of the rest platform beam 10 in the stairwell through the clapboard lugs 2 on both sides. ; The prefabricated reinforced concrete fire partition 1 is bolted to the prefabricated concrete stairs 8 through connecting angle steels (connectors 11 ).

[0029] The prefabricated r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com