Application of steel strand in multi-angle drilling and coring process

A multi-angle, prestressed steel strand technology, applied to drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problem that the recovery rate of rock ore core cannot meet the national standard, cannot exceed the limit of drilling angle, and cannot use rope coring towers To solve problems such as racks, to increase the income of drilling workers, to achieve significant economic effects, and to reduce accidents in the hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

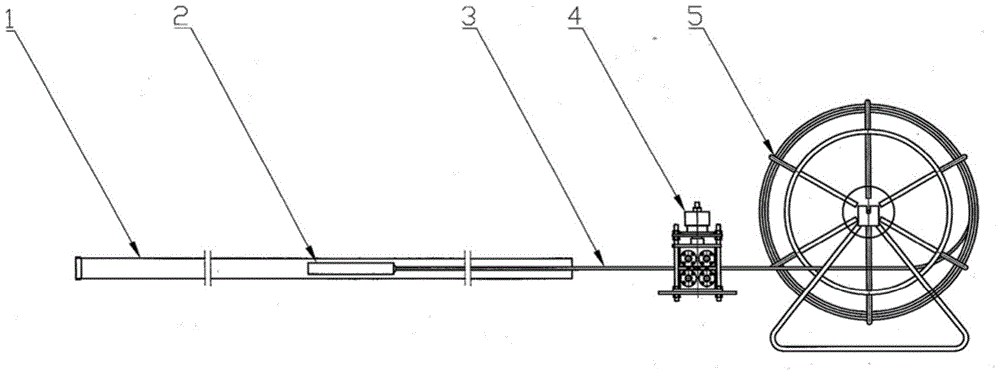

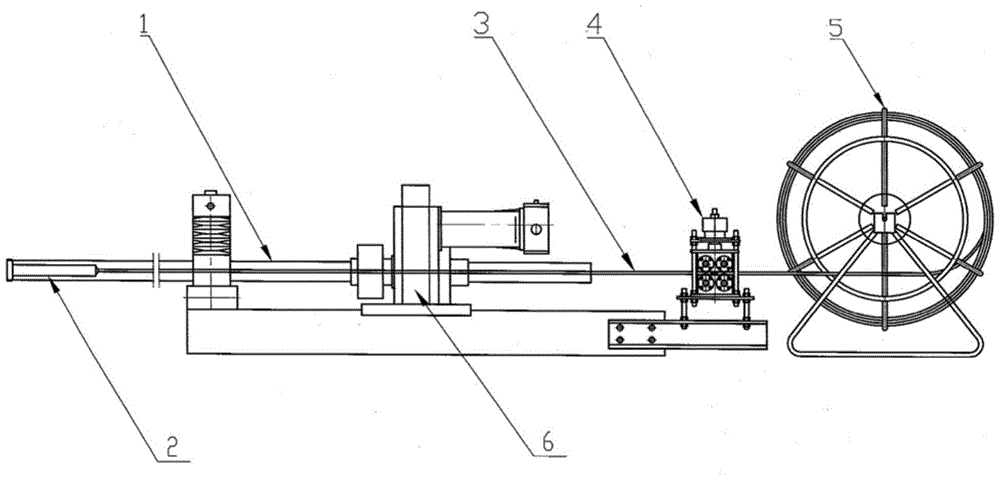

Image

Examples

Embodiment

[0017] Working conditions and equipment

[0018] Downhole horizontal drilling, the working space is 2 meters high and 2 meters wide, using a power head tunnel drilling rig, the oil cylinder stroke is 0.75 meters, and the hole depth is 300 meters. .

[0019] Existing dual-tube coring process operation mode:

[0020] 1. Support the drilling rig at the above drilling site. After checking the safety, start the operation and install the core inner pipe for drilling.

[0021] 2. After the inner tube of the core is fully drilled, (drilling for the first time, the drilling rig can clamp the inner tube of the core) with the effective stroke of the drilling rig, go forward and backward twice to pull out the inner tube of the core, and remove the drill bit and reamer Take out the core, install the drill bit and the reamer to send the inner tube of the core into the hole in two forward and backward steps with the drill cylinder, and then connect the drill pipe to continue drilling.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com