Combined type brush sealing structure with radially adjustable brush wire bundle

A brush-type sealing and combined technology, which is applied in the direction of leakage prevention, engine components, machines/engines, etc., can solve the problems of insufficient closing of the gap between brush filament bundles, friction between brush filament bundles and rotors, increased leakage, etc., to achieve Reduce the straight-through effect, reduce the axial airflow pressure, and increase the effect of flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

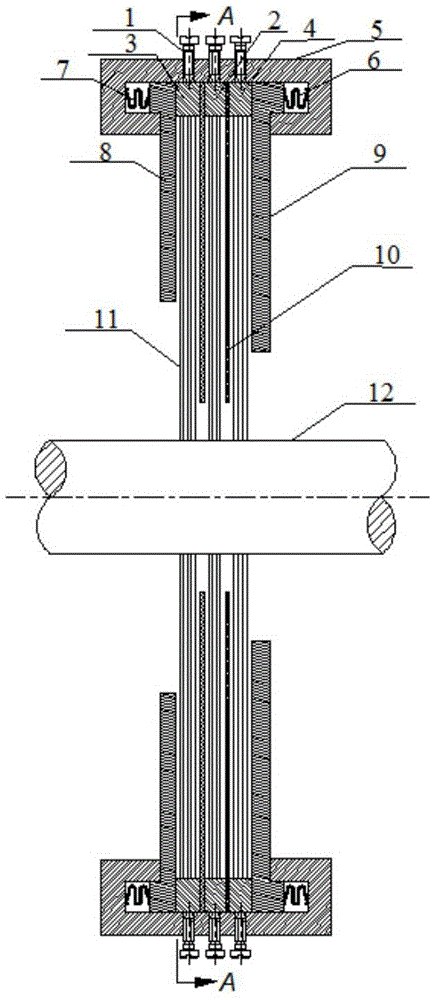

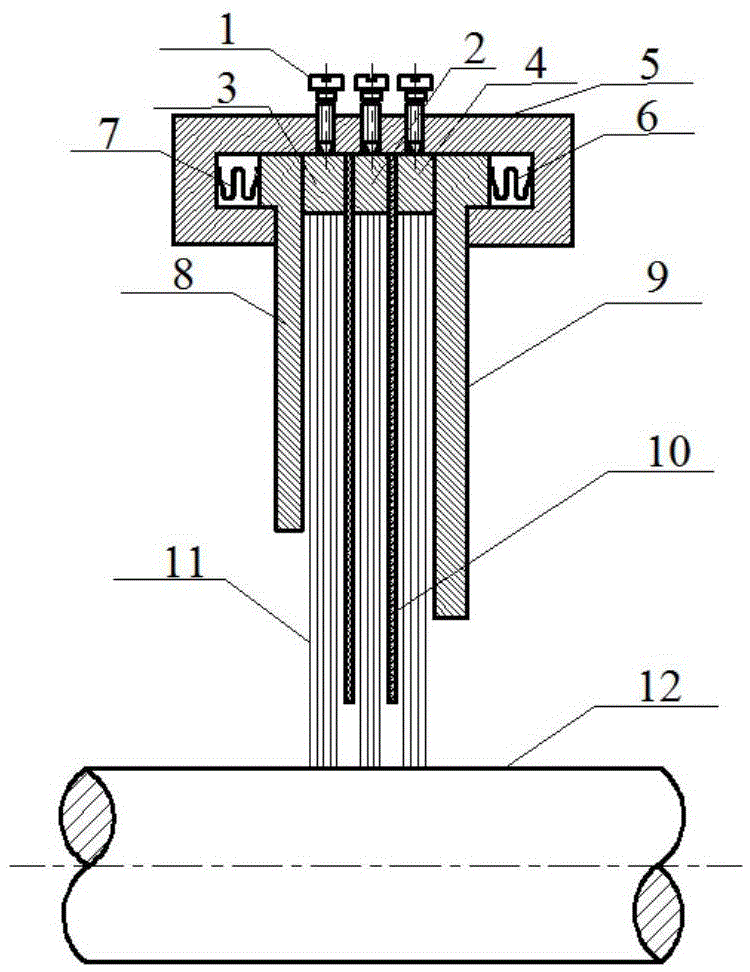

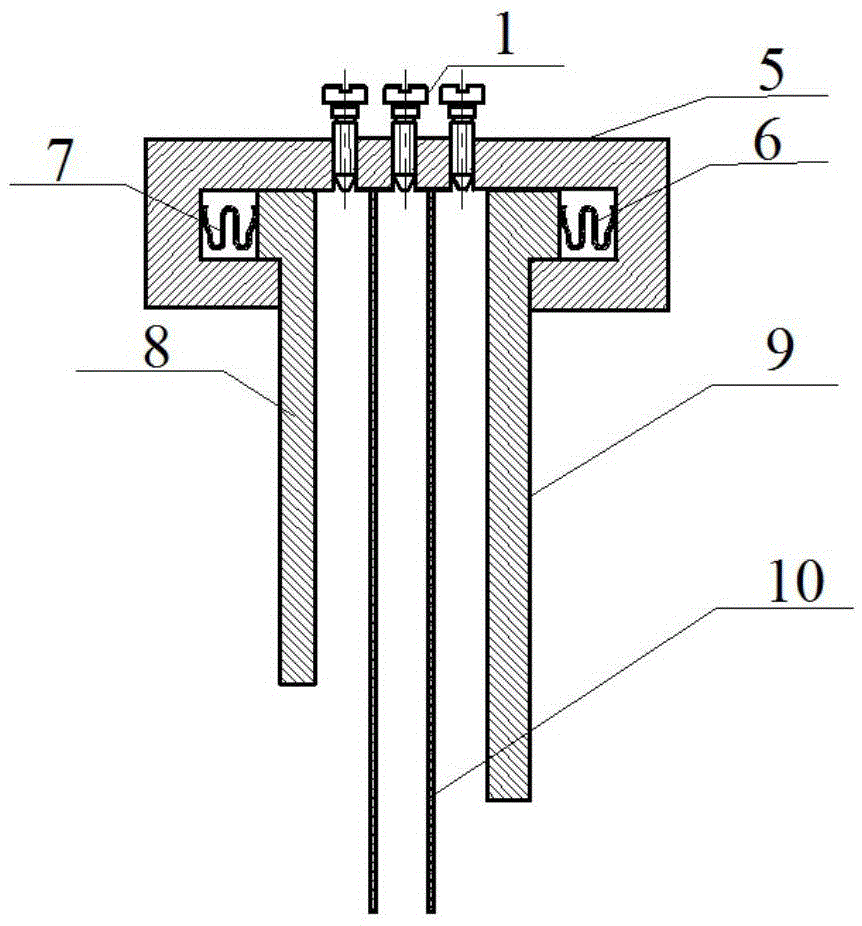

[0023] Such as Figure 1-Figure 7 Shown: a combined brush seal structure with radially adjustable brush bundles, including fastening screw 1, midstream brush ring 2, upstream brush ring 3, downstream brush ring 4, stator case 5, W Type sealing ring 6,7, front baffle 8, rear baffle 9, bearing plate 10, brush wire 11 and rotor 12. The middle brush wire ring 2 , the upstream brush wire ring 3 and the downstream brush wire ring 4 are fixed on the annular plate by the roots of the brush wire 11 through welding process, forming three brush wire rings 2 , 3 , 4 in the upper, middle and lower reaches. The brush wire ring is divided into 3 to 9 segments in the circumferential direction, and a gap of 1 mm to 3 mm is maintained between adjacent segments of the wire brush ring, and 1 to 3 fastening screws are set on the stator case corresponding to each segment of the wire brush ring 1, in order to adjust the radial gap between the brush filament 11 and the rotor 12. The W-shaped seal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com