Aluminum wire drawing front frame circuit board fixing device for intelligent all-in-one machine

A fixing device and circuit board technology, applied in the direction of the circuit arrangement on the support structure, can solve the problems of difficult coordination, beauty and convenience in design and installation, cumbersome and complicated debugging and maintenance work, and beautiful surface of broken aluminum profiles. It is easy to design the process flow, the installation steps are clear and clear, and the effect of reducing replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

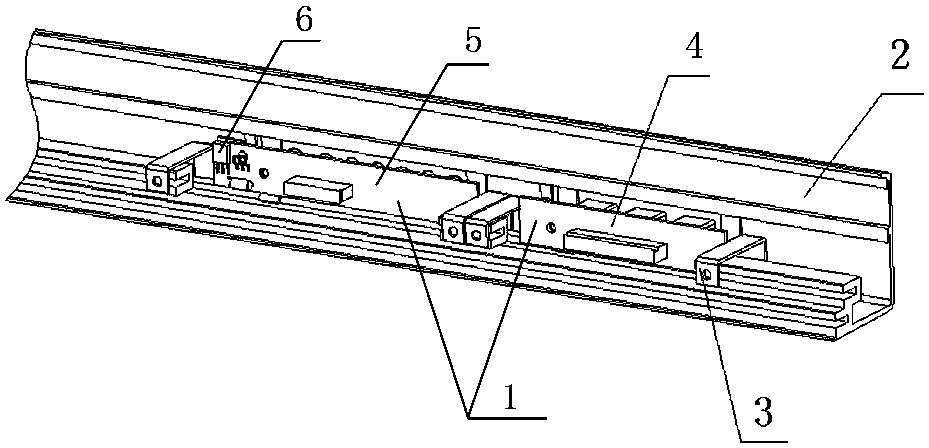

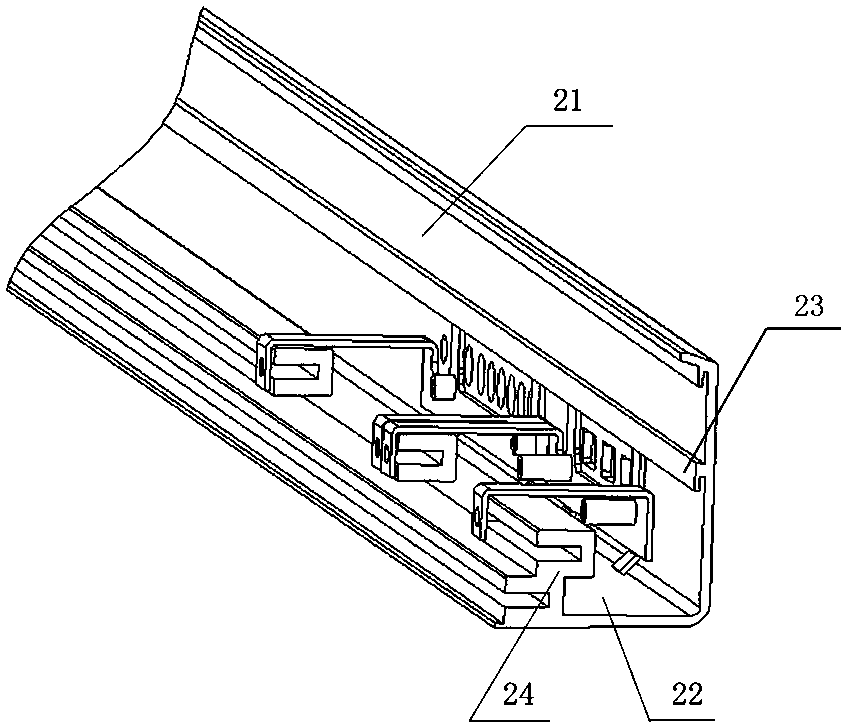

[0042] The circuit board 1 is divided into two pieces, one is a button circuit board 5, and the other is a USB circuit board 4, which are respectively connected to the front frame 2 through a bracket 3, wherein the button circuit board 5 contains an infrared receiver 6, and its function is the same as that of a conventional infrared receiving circuit The functions of the boards are the same, and the fixing methods of the two circuit boards are the same. The reverse side of the circuit board 1 is provided with a cable socket 14. When debugging or changing cables, the cables can be directly disassembled from the cable socket 14 without dismantling other parts.

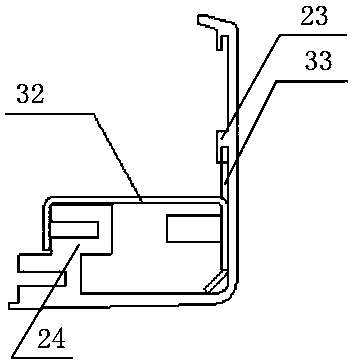

[0043] For the button circuit board 5 and the USB circuit board 4, a corresponding through hole 23 is opened in the front frame 2, and its shape, distance and relative position are completely corresponding to the circuit board 1. Considering the installation, debugging and process performance of the circuit board 1, the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com