Multi-stage brush type seal of multi-stage differential structure

A brush-type seal and differentiated technology, applied in the direction of leakage prevention, engine components, machines/engines, etc., can solve the problems of large pressure drop and seal failure in the downstream stage, and achieve the effects of balanced pressure drop, easy control, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with specific embodiments, but the present invention is not limited thereto.

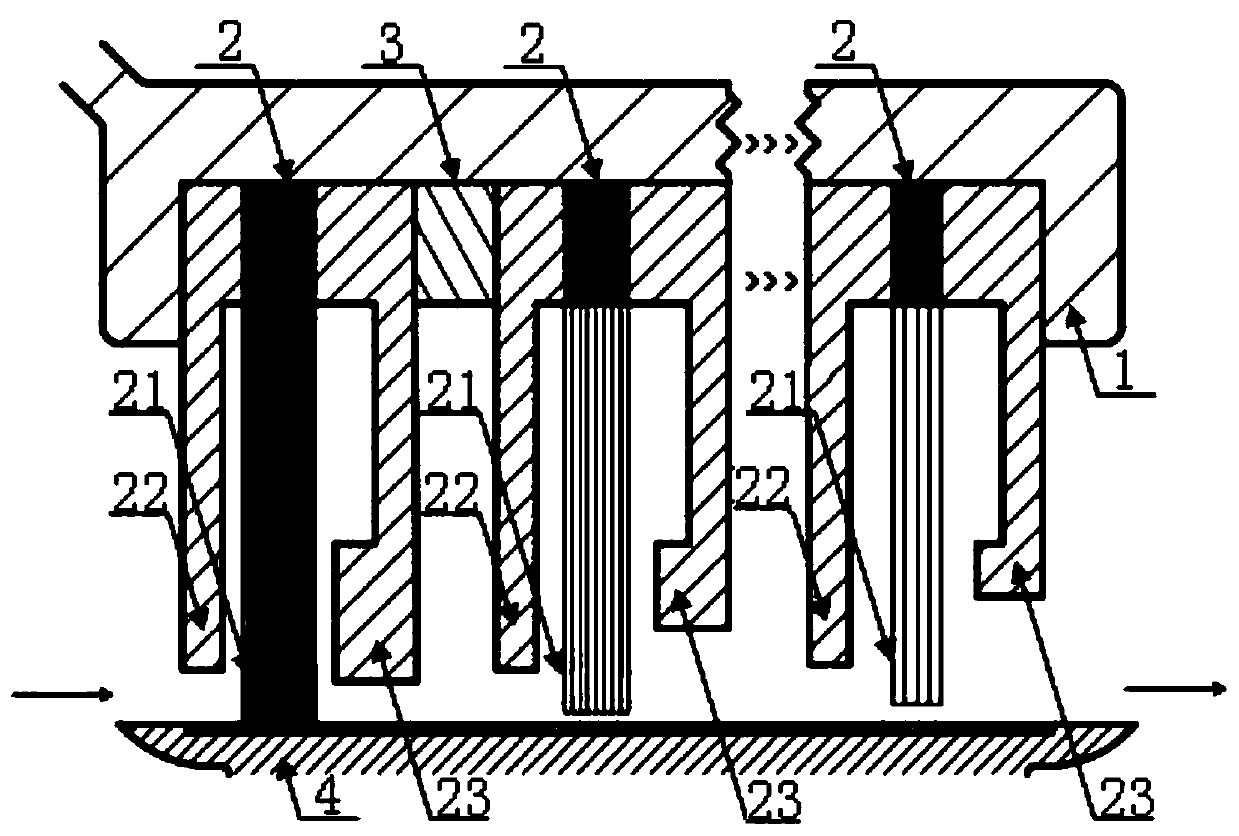

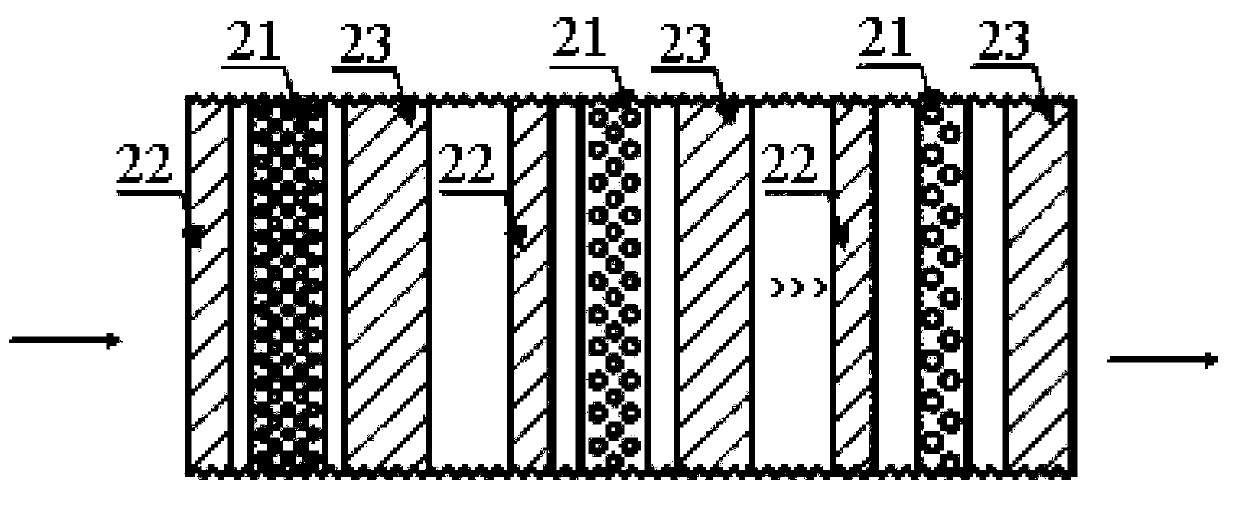

[0020] Such as figure 1 , figure 2 As shown, the present invention provides a multi-stage brush seal with different levels of structure, including: a brush seal mounting seat 1, a multi-stage brush seal unit 2 and correspondingly arranged between adjacent brush seal units 2 The partitions 3, the brush seal units 2 at all levels include brush filament bundles 21, front baffles 22 and rear baffles 23, and the partitions are used to ensure the axial distance between the brush seal units at all levels. In the direction of the brush seal unit from the upstream stage to the downstream stage, the radial gap between the free end of the brush filament bundle 21 of the brush seal unit 2 of each stage and the surface of the rotor 4 increases step by step and the brush filament of the brush seal unit 2 of the first stage There is an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com