Circulating water pump and method for transforming same

A technology for circulating water pumps and water pumps, which is applied to components, pumps, and pump devices of elastic fluid pumping devices, and can solve problems such as increased renovation costs, high costs, and impacts on the promotion of energy-saving technologies, and achieve good energy-saving effects. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

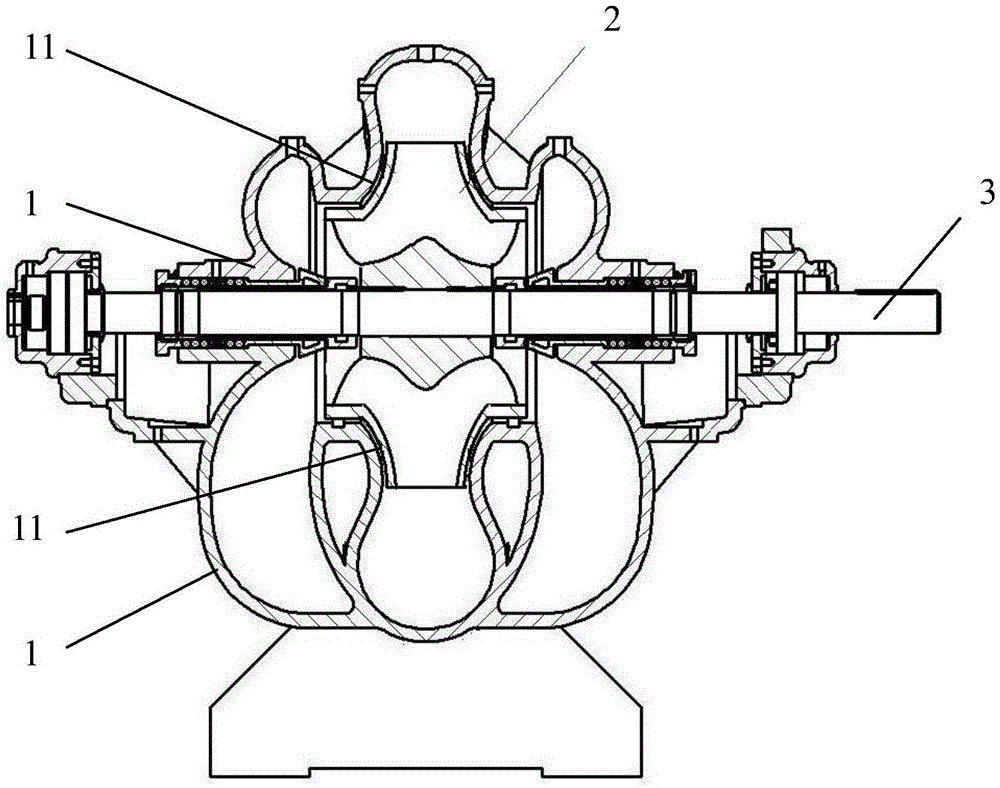

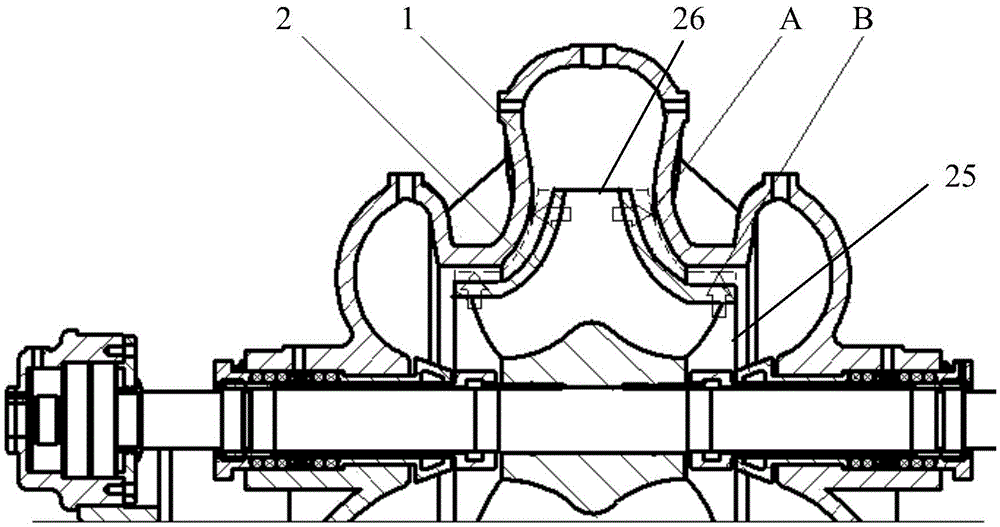

[0042] Such as figure 1 As shown, the circulating water pump includes a water pump volute 1, an impeller 2 and a transmission shaft 3 located in the water pump volute 1, the impeller 2 is sleeved on the transmission shaft 3 and fixedly connected, and a motor (not shown in the figure) for driving the transmission shaft 3 Show). When working, the motor drives the transmission shaft 3 to rotate, the transmission shaft 3 drives the impeller 2 to rotate, and the impeller 2 drives the water circulation of the water pump volute 1 at the same time.

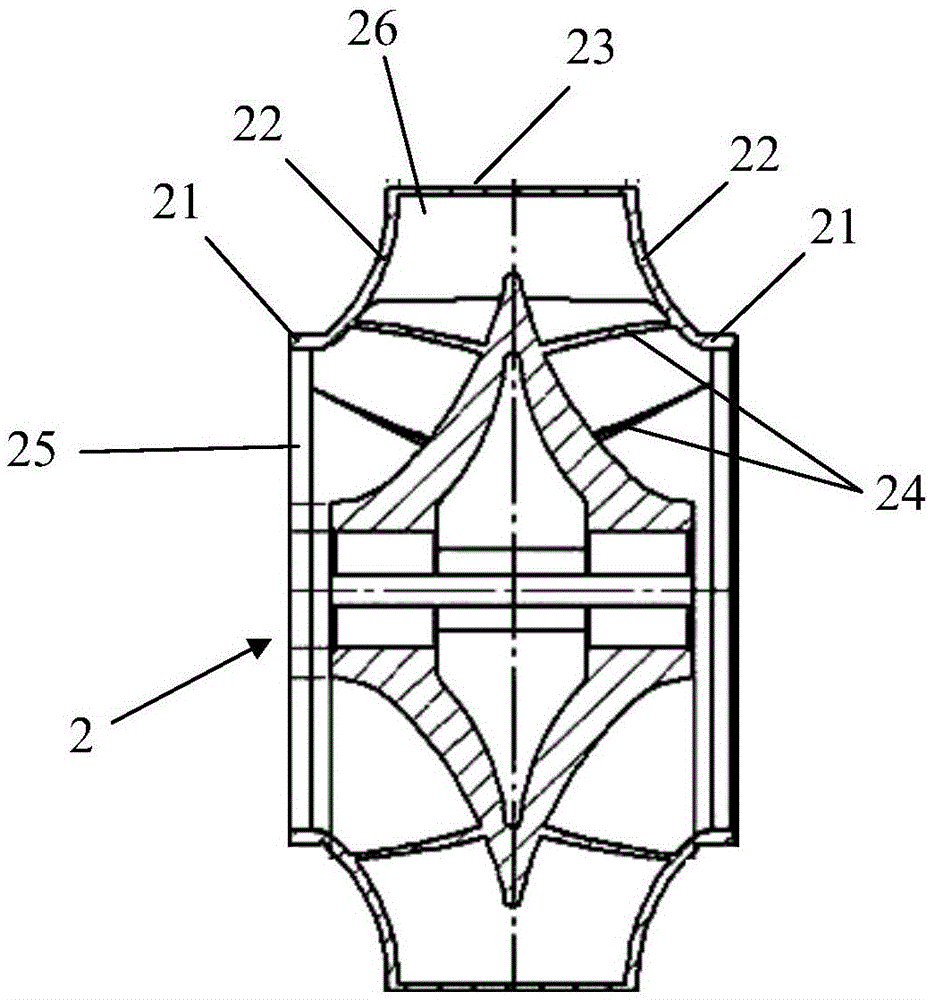

[0043] In this example, if figure 2 As shown, the impeller 2 includes two cylindrical bodies 21 symmetrically distributed from both sides to the center, two bell mouths 22 symmetrically distributed and whose diameter gradually increases from both sides to the center, and an impeller body 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com