Expansion sleeve buffer coupling

A coupling and expansion sleeve technology, applied in couplings, elastic couplings, mechanical equipment, etc., can solve the problems of easily damaged internal bearings of the main engine, damage to the hydraulic system, easy wear of splines, etc., and is easy to popularize. The effect of using and transmitting large torque and good backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

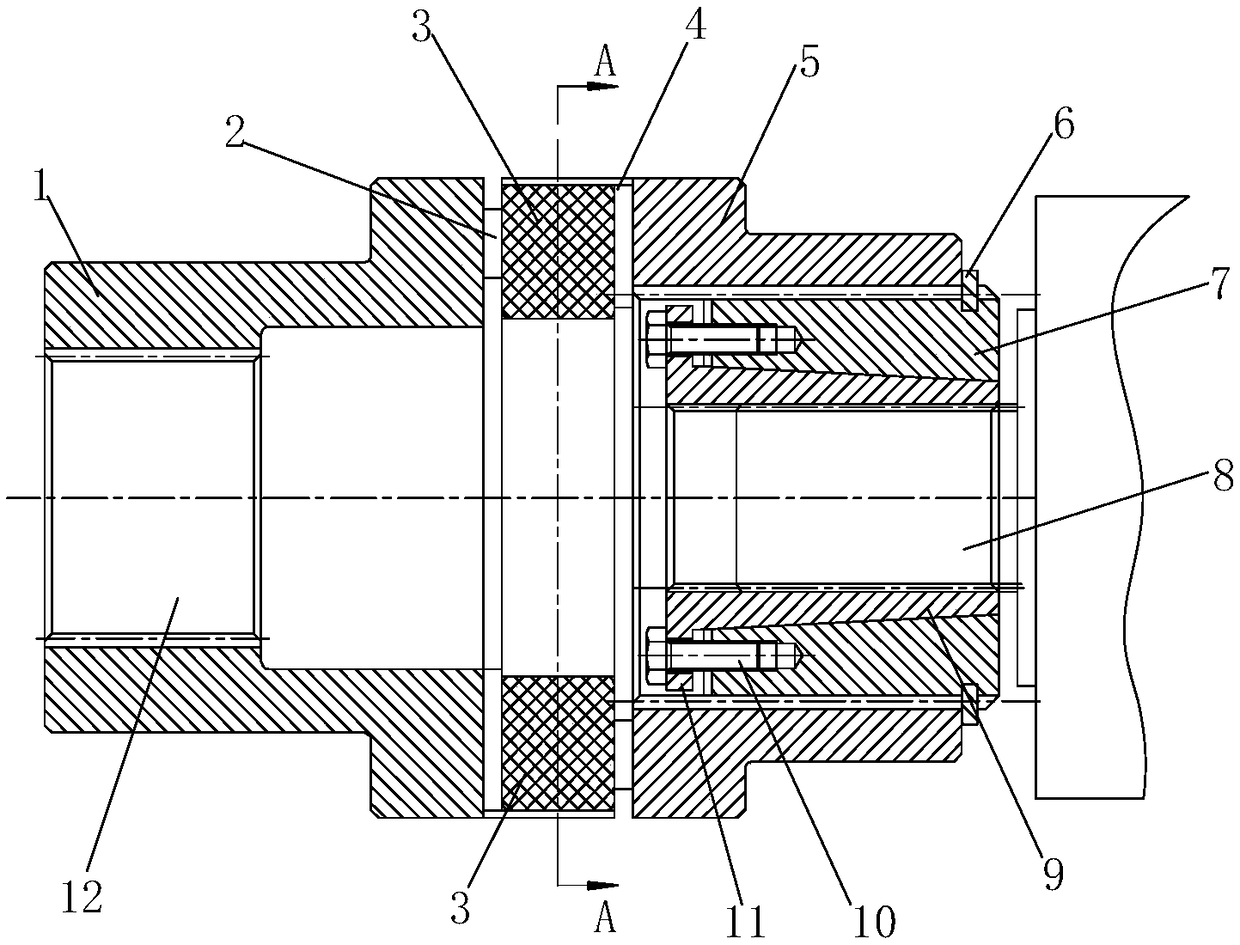

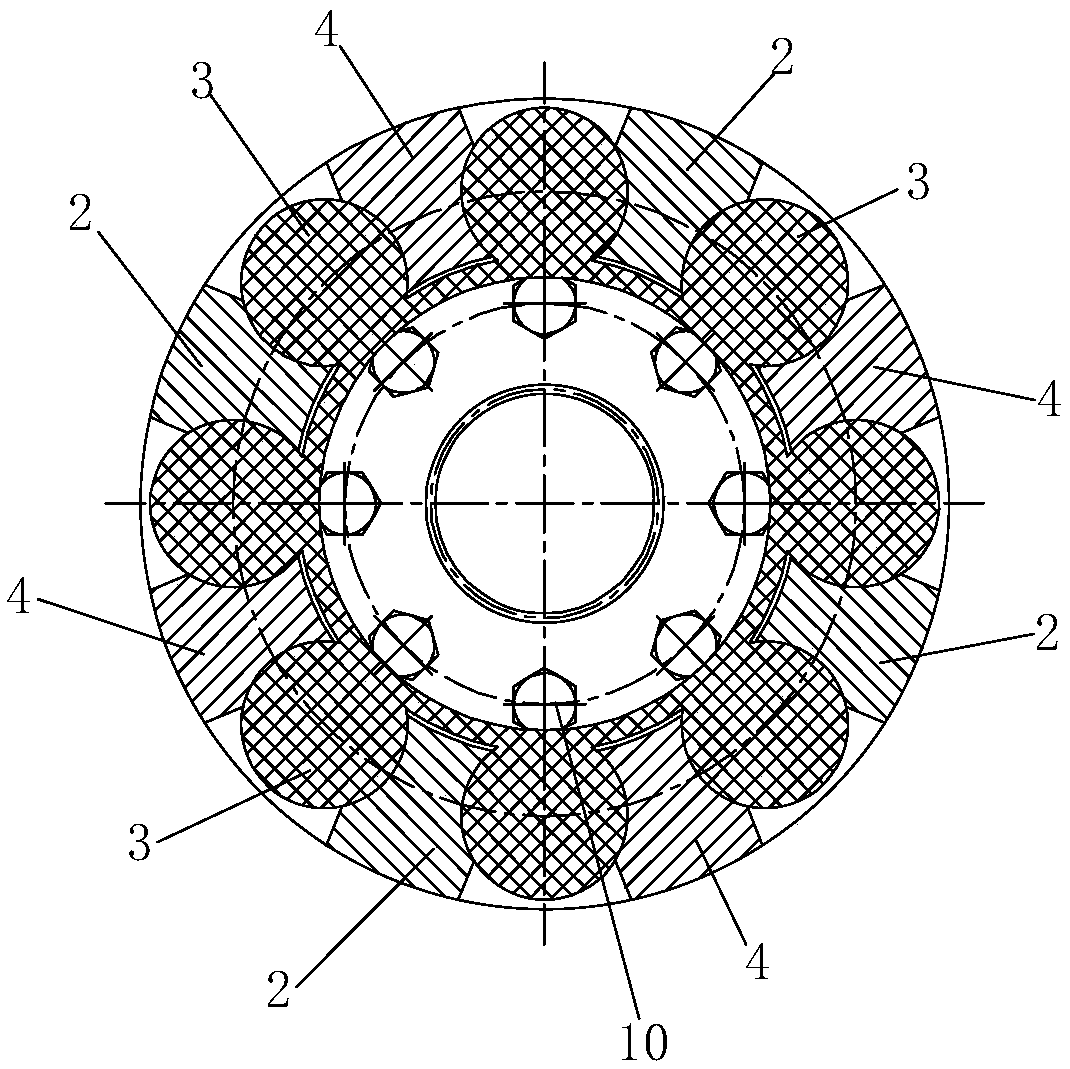

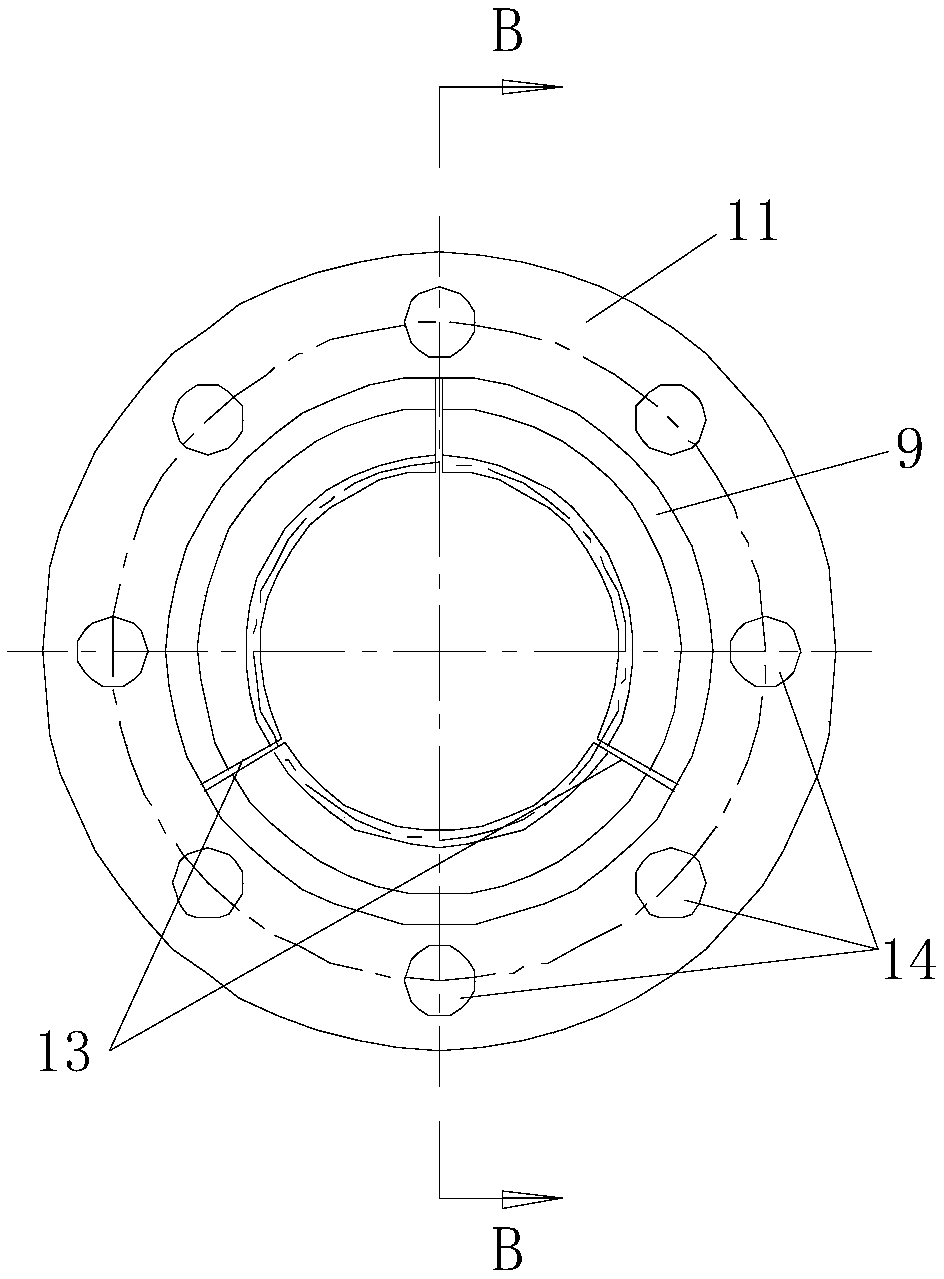

[0026] Such as figure 1 The shown expansion sleeve buffer coupling includes a torque input sleeve 5 and a torque output sleeve 1 connected to the torque input sleeve 5, and the torque output sleeve 1 is connected to the driven shaft 12 spline connection, the torque input end casing 5 is provided with an inner fastening sleeve 9 and an outer fastening sleeve 7 set on the inner fastening sleeve 9, and the inner fastening sleeve 9 is connected to the drive shaft 8 Splined connection, the outer fastening sleeve 7 is splined connected with the torque input end sleeve 5, the inner fastening sleeve 9 and the outer fastening sleeve 7 are tapered, and the inner fastening sleeve 9 is close to the torque input One end of the end sleeve 5 is provided with a radial protruding plate 11 , and the radial protruding plate 11 is provided with a connecting bolt 10 extending into the outer fastening sleeve 7 . Specifically, the radial convex plate 11 is provided with threaded holes 14 for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com