Opposite-side double-output-shaft large-transmission-ratio speed reducer with self-locking function

A dual output shaft, ratio reducer technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of small transmission ratio range, single output, single input of reduction device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

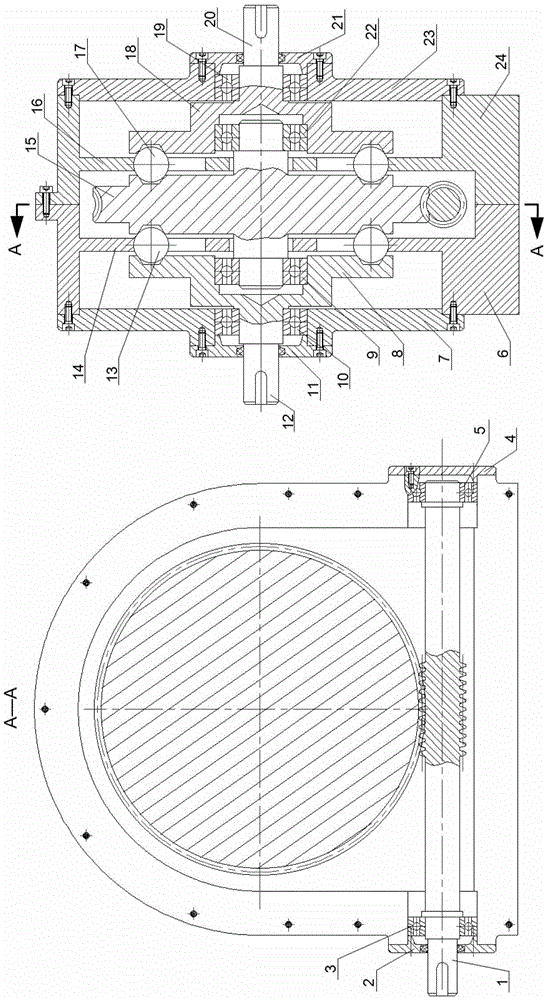

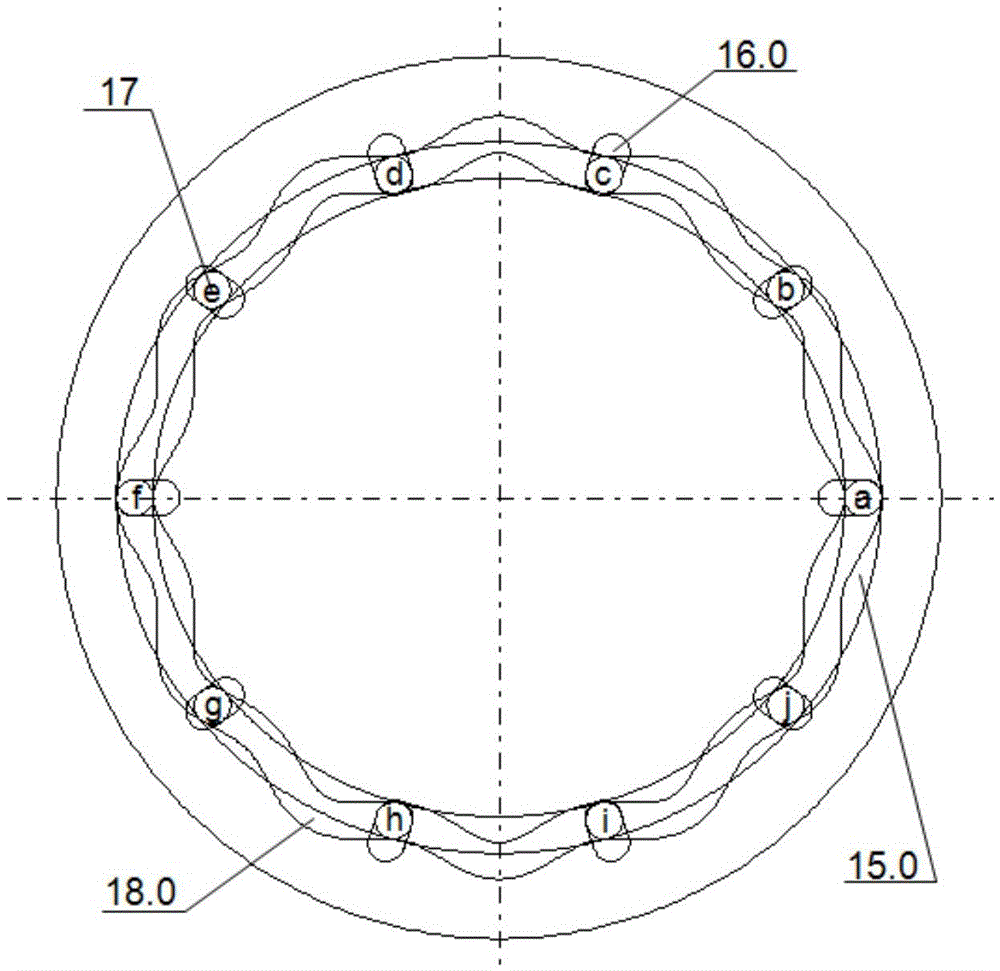

[0025] Such as figure 1 , Figure 2-1 to Figure 2-5 As shown, the speed reducer includes an input shaft 1, a multi-function disc 15, a left steel ball 13, a right steel ball 17, a left movable rack 14, a right movable rack 16, a left output disc 8, a right output disc 18, and a left output Shaft 12, right output shaft 20, left frame 6, right frame 24. The input shaft 1 and the multifunctional disk 15 transmit motion through tooth profile engagement; the frame is composed of a left frame 6 and a right frame 24, and the left movable gear frame 14 and the right movable gear frame 16 are fixedly connected to the left frame 6 and the right frame respectively. On the frame 24, the left steel balls 13 are evenly distributed in the radial grooves distributed along the circumferential direction on the left movable rack 14, and are always in the interlacing of the tooth profile grooves on the left end surface of the multi-function disk 15 and the tooth profile grooves of the left outpu...

Embodiment approach 2

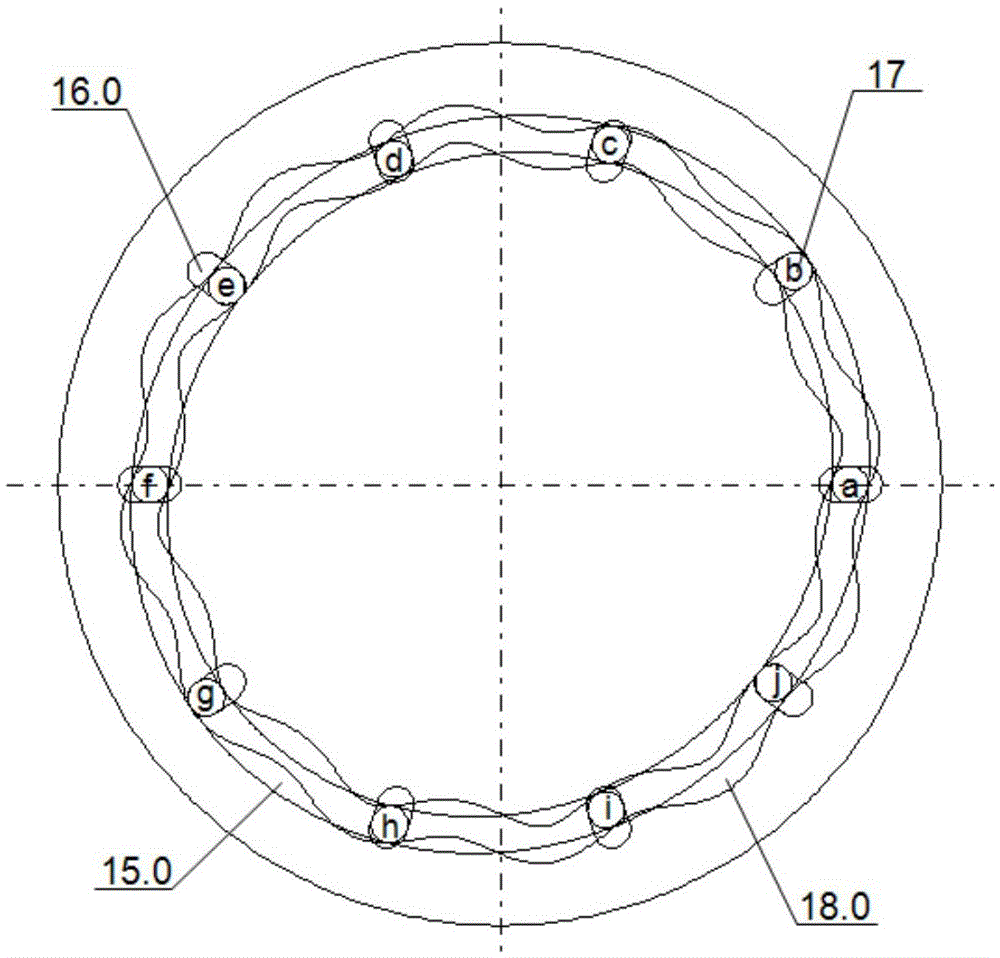

[0028] This embodiment is the same as Embodiment 1 in terms of the transmission principle of the movable tooth transmission mechanism, the difference lies in the transmission ratio i=-6 of the movable tooth transmission mechanism of Embodiment 2, that is, the direction of rotation of the multi-function disk and the right output disk is opposite. The tooth profile groove diagram of the component is as follows Figure 3-2 to Figure 3-4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com