Rolling type online egg crack detecting device on basis of parallel piezoelectric film arrays

A piezoelectric film and crack detection technology, which is applied in the field of poultry egg quality online detection, can solve problems such as egg shell damage and cracks, and achieve the effects of convenient control, avoiding misjudgment of cracks, and simplifying the signal excitation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

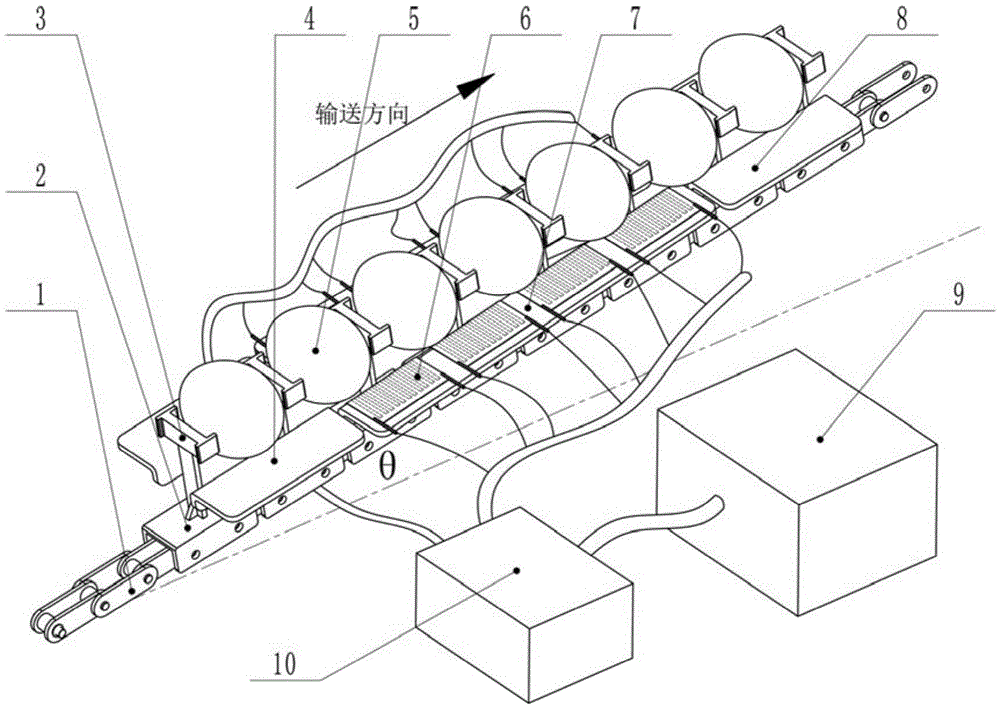

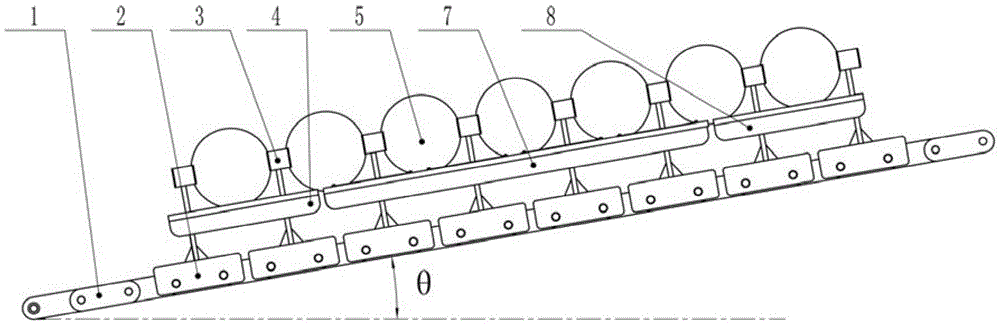

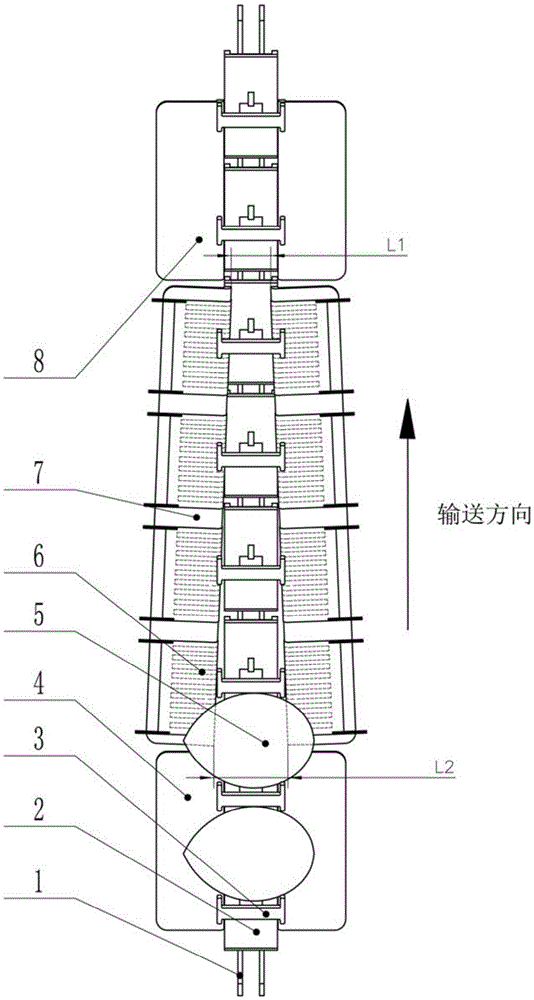

[0033] like figure 1 As shown, the device of the present invention that is specifically implemented includes a conveyor chain 1, a poultry egg propulsion mechanism, a front track 4, four parallel piezoelectric film arrays 6, a detection track 7, a rear track 8, a data acquisition and processing system 9 and a signal conditioning circuit 10. Conveyor chain 1 can select the double-pitch chain of pitch P=25.4mm for use, and poultry egg propelling mechanism is equipped with at equal intervals on conveying chain 1, poultry egg 5 is clamped between adjacent poultry egg propelling mechanisms; Conveying chain 1 Two poultry egg rails parallel to the conveying chain 1 are arranged symmetrically on both sides. The poultry egg rails include front-end rail 4, detection rail 7 and rear-end rail 8 along the conveying direction. Four parallel piezoelectric film array...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com