Customization making method and system in footwear industry

A manufacturing method and custom system technology, applied in the general control system, control/adjustment system, program control, etc., can solve problems such as easy waste of resources, insufficient collection of customized information, lack of communication between customers and manufacturers, and reduce inventory Pressure, reduce production cost, save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

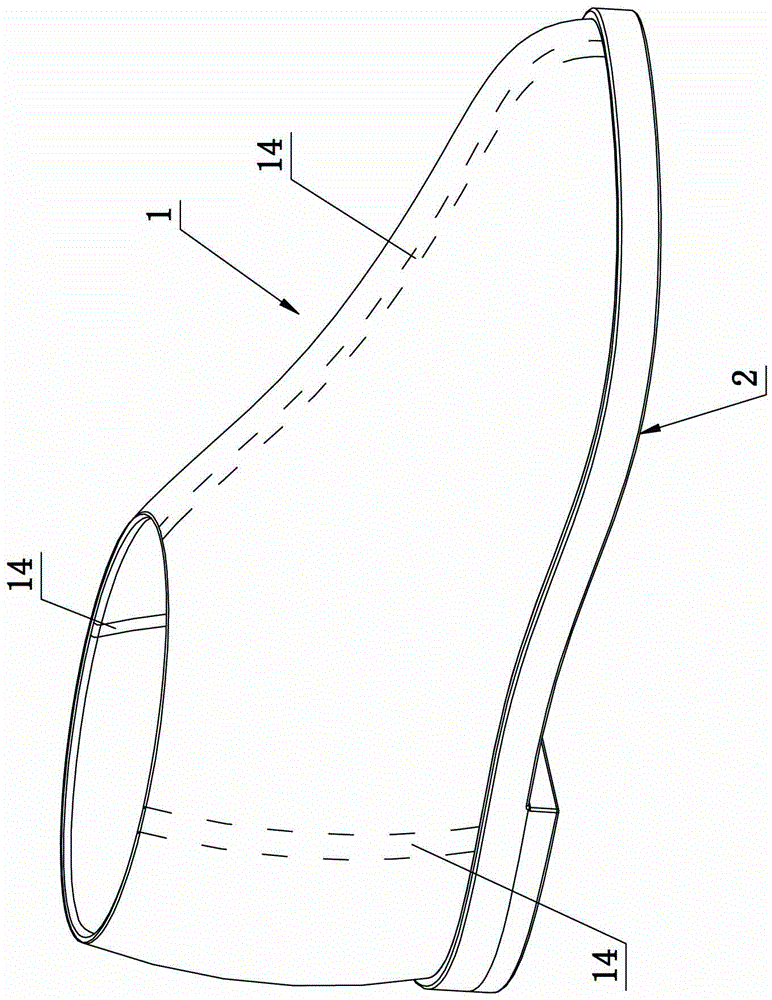

[0037] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

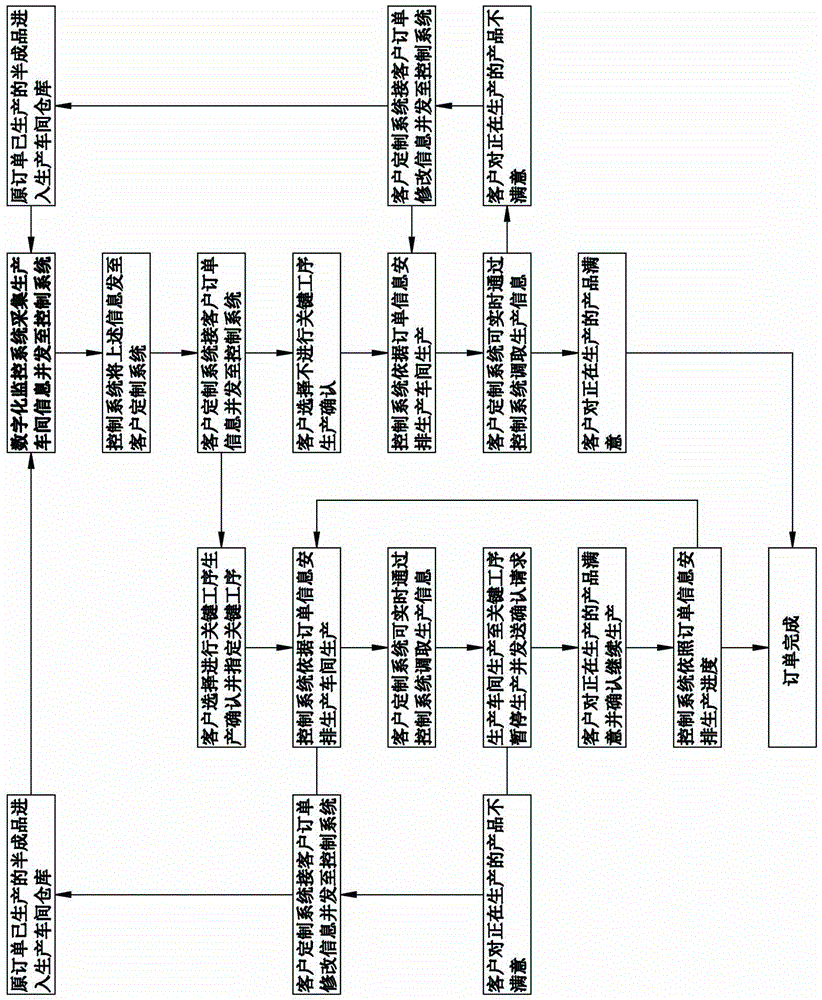

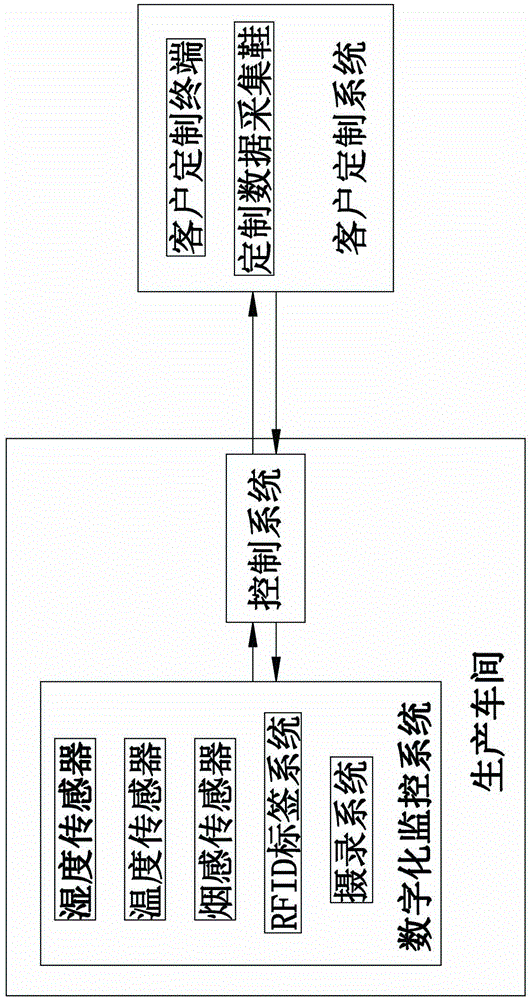

[0038] refer to figure 2, A customized manufacturing system for footwear, including a production workshop and a digital monitoring system, a control system and a customer customization system arranged in the production workshop. The above-mentioned digital monitoring system includes a humidity sensor, a temperature sensor, a smoke sensor, an RFID tag system and a recording system. The above-mentioned digital monitoring system is controlled by the above-mentioned control system, and the above-mentioned customized system can be connected to the control system through the Internet. The above-mentioned production workshop includes equipment, workshops and warehouses required for the production of products. The above-mentioned digital monitoring system is assembled in the equipment, workshop and warehouse of each production process in the production worksho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com