OLED display device and packaging method thereof

A technology of a display device and a packaging method, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems affecting the service life of OLED devices, achieve the effects of reducing consumption and production costs, and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

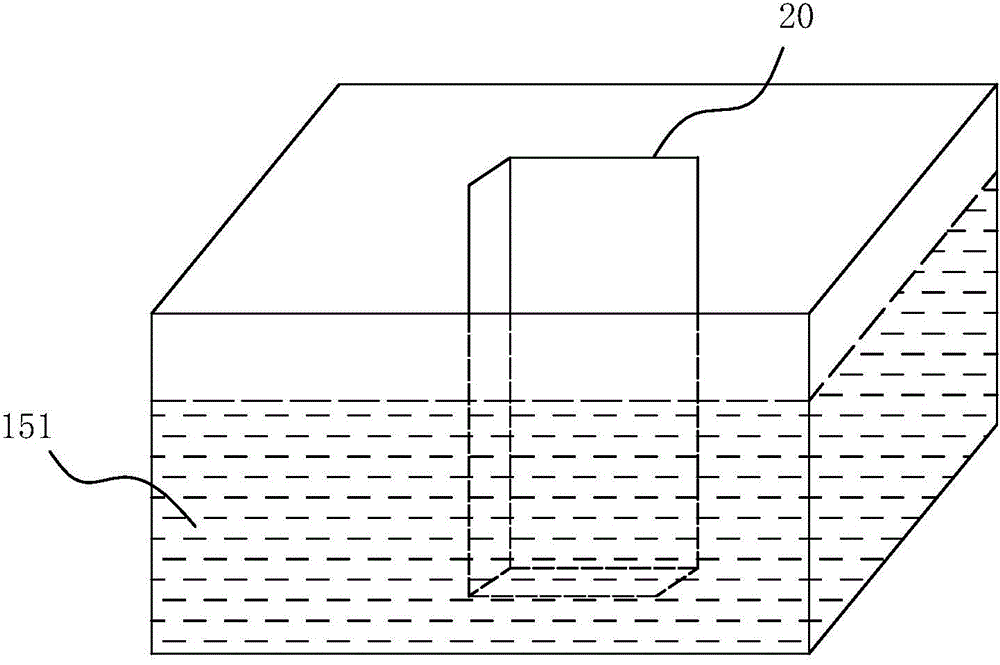

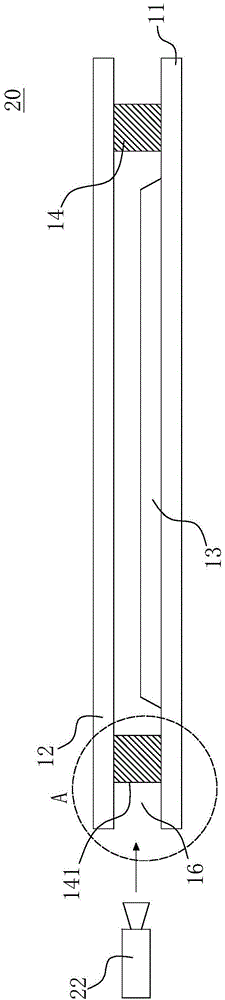

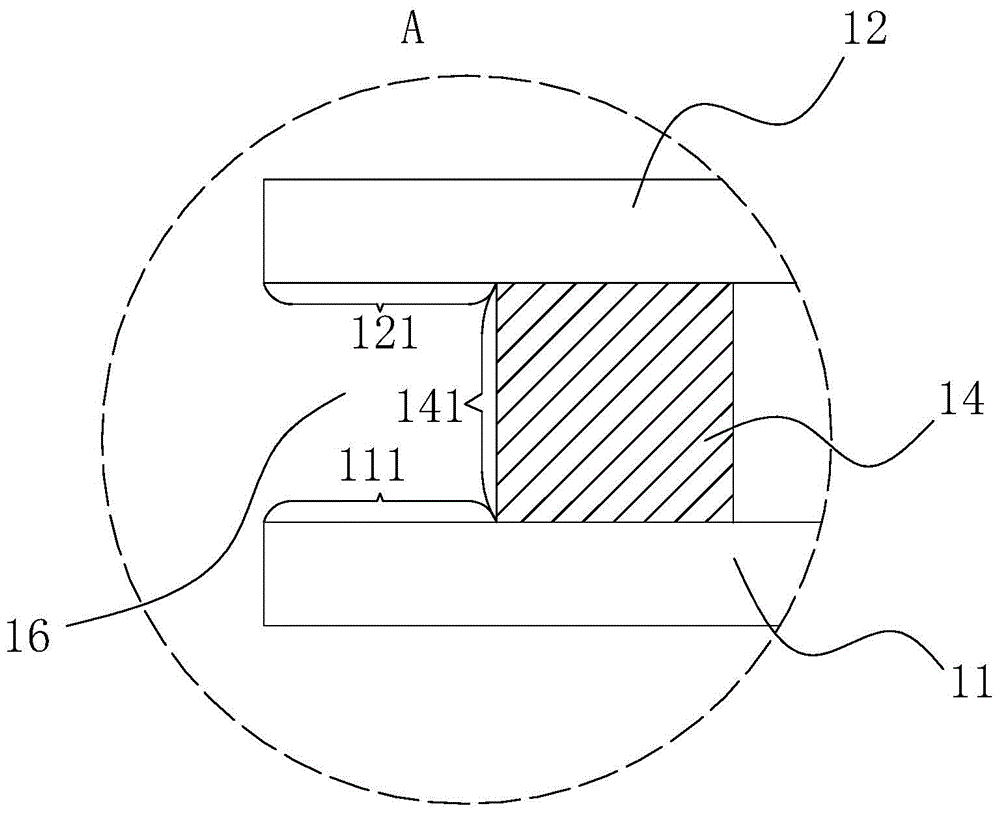

[0027] Such as Figure 4 As shown, the OLED display device 10 of the present invention includes: a first substrate 11, a second substrate 12, a first encapsulation structure 14 and a second encapsulation structure 15, the first encapsulation structure 14 is arranged on the first substrate 11 and the second substrate 12 to seal at least one organic light emitting display unit 13 in a space surrounded by the first substrate 11 , the second substrate 12 and the first packaging structure 14 . The second encapsulation structure 14 is disposed in a predetermined area 16 between the first substrate 11 and the second substrate 12 and the first encapsulation structure 14 .

[0028] The first encapsulation structure 14 and the second encapsulation structure 15 may be disposed in a ring shape between the first substrate 11 and the second substrate 12, and the second encapsulation structure 15 is adjacent to the first encapsulation structure 15. A packaging structure 14 . The second enc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com