Post-packing overhead coordination conveyor

A technology of conveying equipment and conveying devices, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of unfavorable dairy factories and difficulty in keeping the transportation corridor clean, and achieve the effect of easy and simple formation of lateral movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

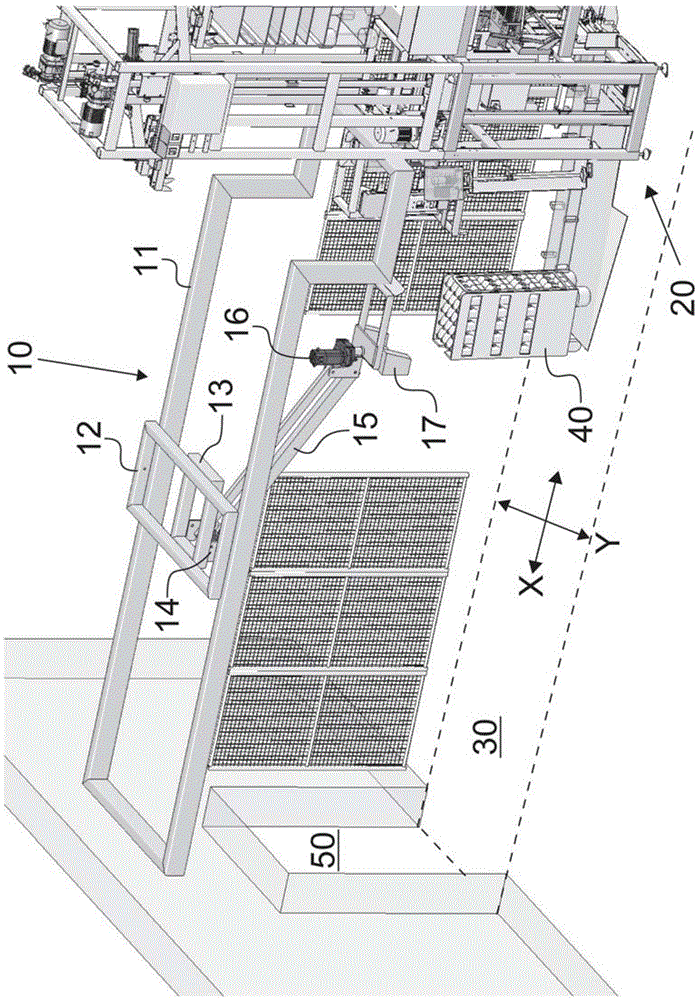

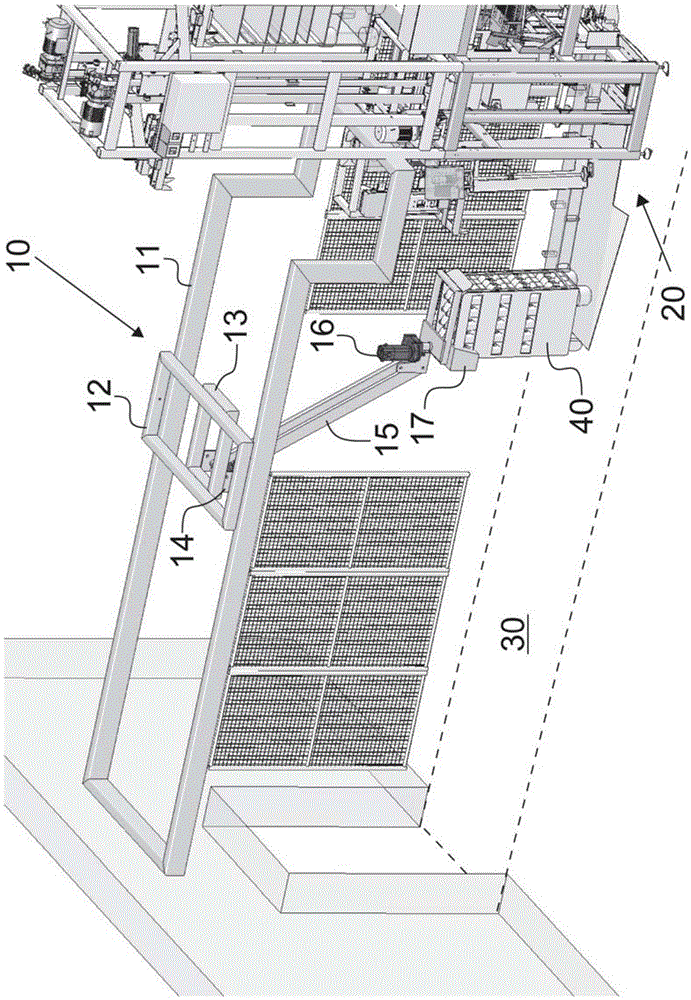

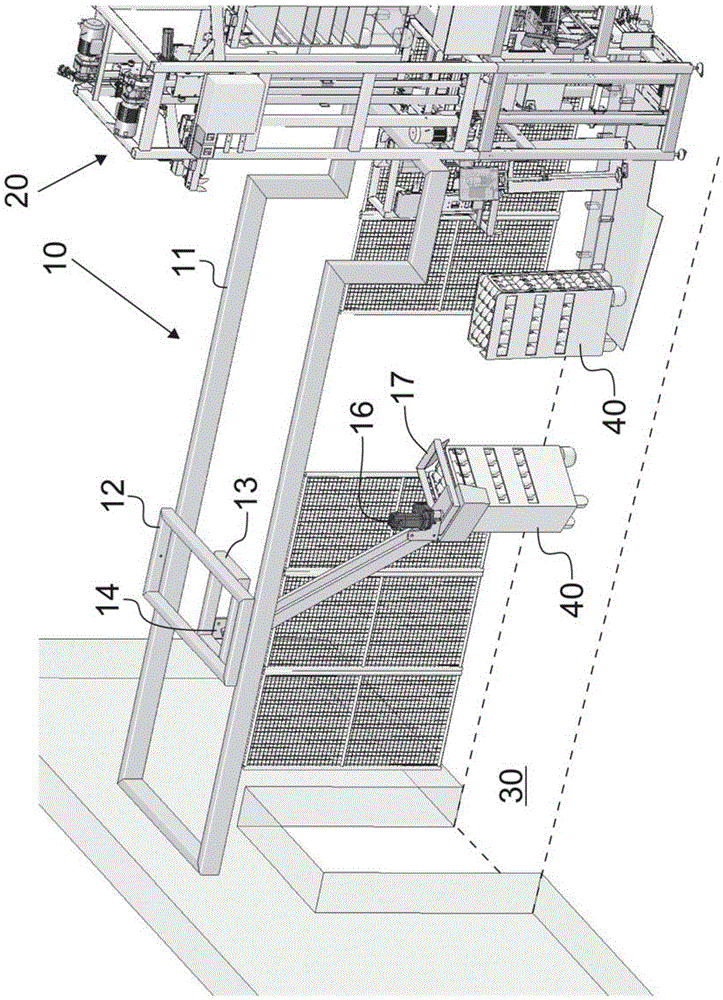

[0019] Such as Figure 1 to Figure 5 As shown, a conveying device according to the invention may be arranged in connection with a production line 20 for transporting self-rolling load carriers 40 away from the production line. In more detail, a particular application of the conveyor device is a production line, where load carriers coming from the end of the packaging plant have to be transported to the outside 50 of the production line 20 . A dairy could be an example of an application where packaging equipment packs lotion containers into roll-on containers 40 and there is a need to seamlessly transport the lotion containers to cold storage 50 . It is however evident that the conveyor device according to the invention can be applied to many different production lines and to many different self-rolling (ie wheeled) load carriers. According to one embodiment, the load carrier 40 is a rolling container. According to another embodiment, the load carrier 40 is a sliding trolley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com