Threaded fitting and method for connecting a fitting on a threaded connection

A threaded connection and pipe joint technology, applied in the field of pipe joints, can solve problems such as time-consuming inspection of tightness, thread or component damage, etc., and achieve the effect of avoiding indirect damage, high tightness, and eliminating operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

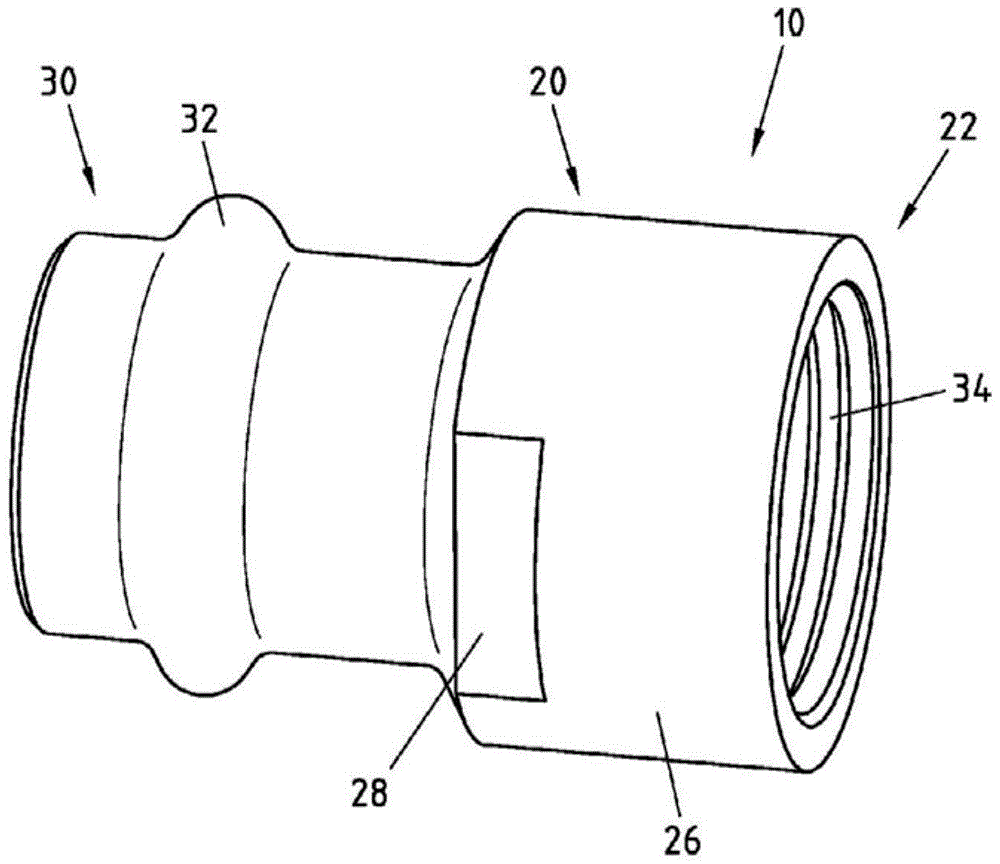

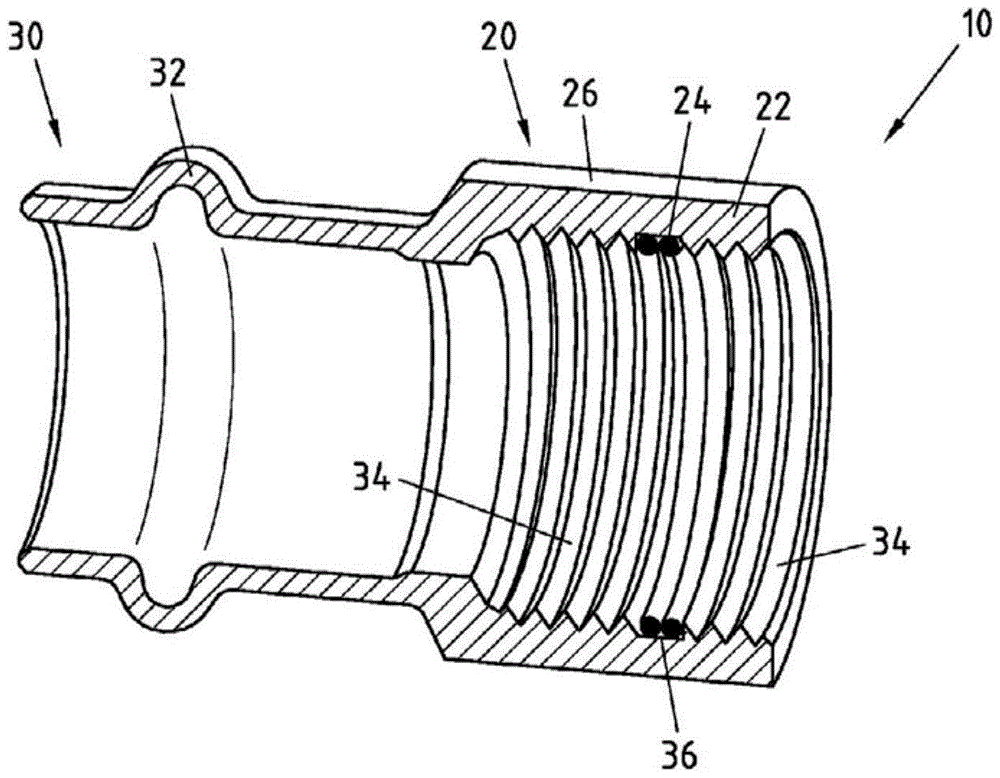

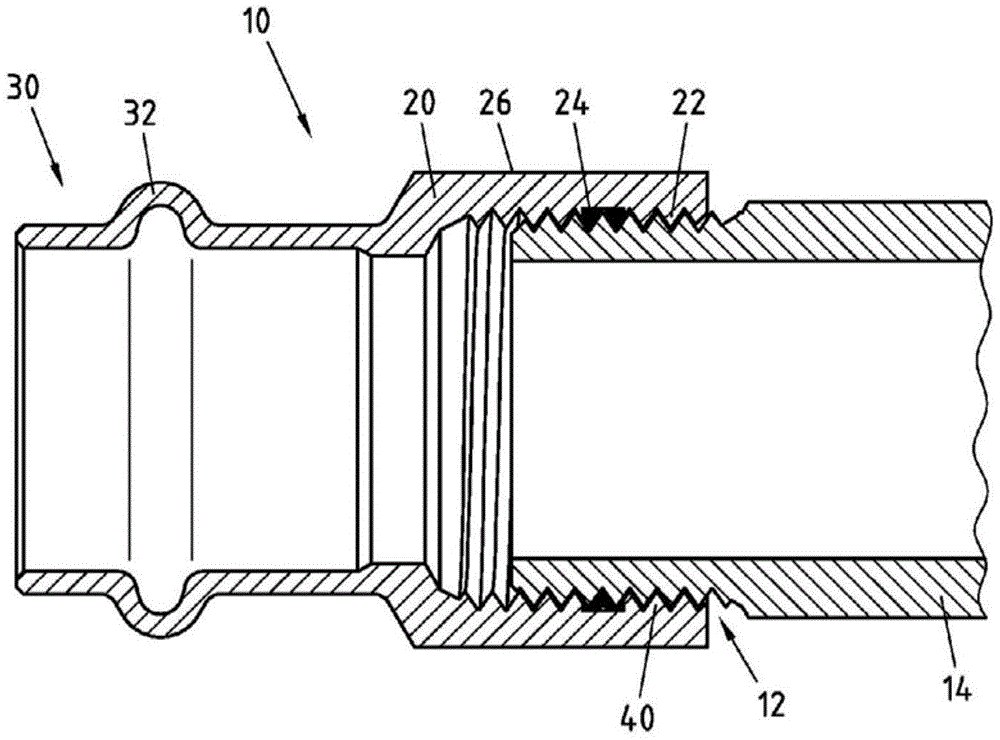

[0052] Figures 1 to 4 A first exemplary embodiment of a pipe connection 10 according to the invention is shown for connection to a threaded connection 12 of a pipe 14 , which may in particular be a water pipe.

[0053] Such as figure 1 and 2 As shown, the pipe connection 10 has a base body 20 , a threaded section 22 and a sealing body 24 arranged on the threaded section 22 . In addition, the base body 20 has a pressing surface 26 on the side radially opposite the threaded section 22 . The pressing surface 26 is formed in a cylindrical shape. The base body 20 also has a flat section 28 which is used to accommodate a screwdriver during the screwing of the pipe connection 10 .

[0054] On the end 30 opposite the threaded section 20 , the pipe connection 10 has a customary projection 32 for receiving an annular seal. That is to say, the end 30 can be used for a conventional press connection to a connecting pipe. The specific design of the squeeze fitting at the end 30 is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com