Crystallizer

A crystallizer and chamfering edge technology, which is applied in the field of mold copper tubes for efficient production of high-quality chamfered blanks, can solve the problems of restricted application, easy occurrence of breakouts or longitudinal cracks, etc., so as to improve production efficiency and reduce corner cracks , The effect of high speed production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

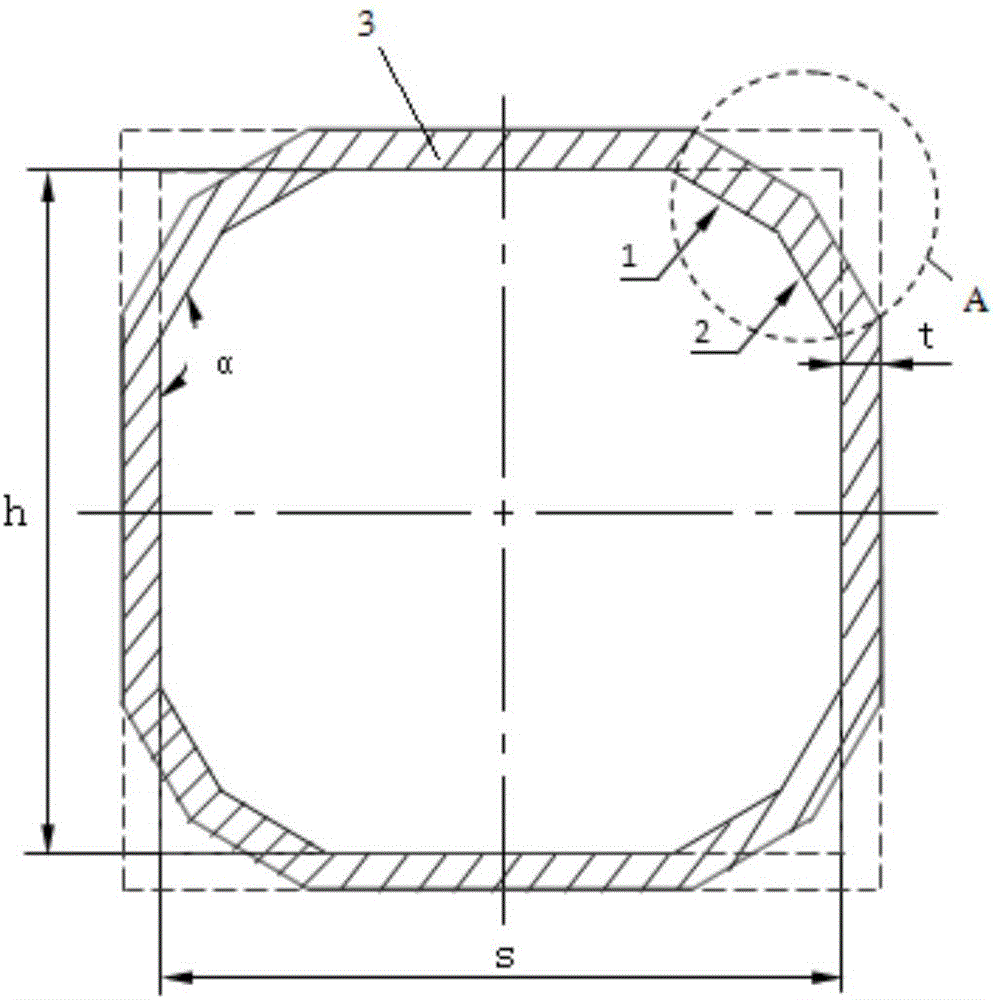

[0042] combine figure 1 As shown, this embodiment is applied to the crystallizer of a billet continuous casting machine in a steel factory. The height h of the inner cavity of the lower mouth of the copper tube of the mold is 142mm, the width s is 142mm, and the length of the mold is 1000mm. It is a tubular mold, and the mold The wall thickness of the copper pipe is t=12mm, and the taper is 4.0%. It mainly produces cord steel, prestressed steel strand high carbon steel, spring steel, etc.

[0043] Chamfering A begins at 27mm from the corner of side wall 3, and there are 2 chamfering sides. The included angle α between the chamfered sides 1 and 2 is also 150°, the lengths of the chamfered sides 1 and 2 are both 19.8 mm, and the intersecting angle α adopts a circular arc transition.

[0044] After the copper tube of the chamfering crystallizer is put on the line, the casting speed is 2.0-2.85m / min.

[0045] After adopting this embodiment, there is no crack at the corner of the...

Embodiment 2

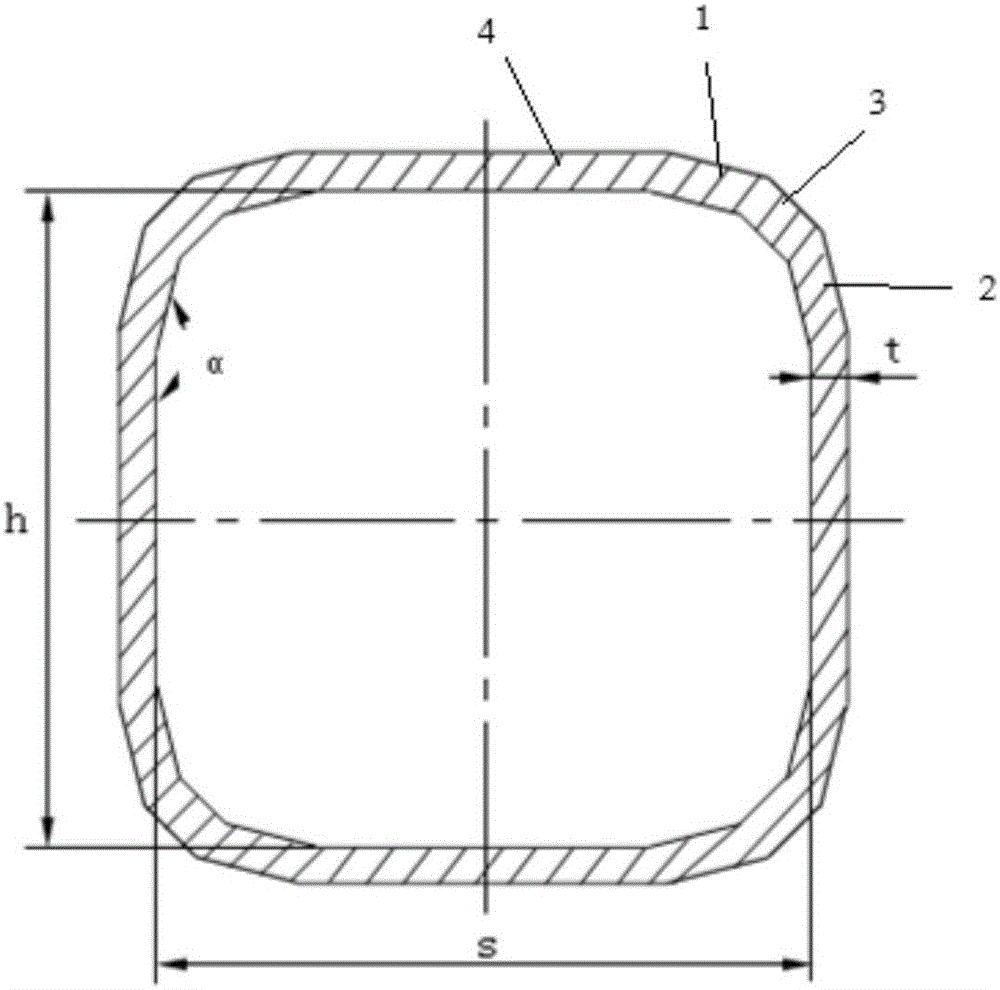

[0047] combine figure 2 As shown, this embodiment is applied to the crystallizer of a rectangular bloom continuous casting machine in a steel factory. The height h of the inner cavity of the lower opening of the mold is 300mm, the width s is 390mm, and the length of the mold is 800mm. It is a tubular mold, and the mold copper The wall thickness of the tube is t=12mm, and the taper is 4.0%. It mainly produces cord steel, spring steel, bearing steel, high-strength cable steel, alloy tool steel, etc.

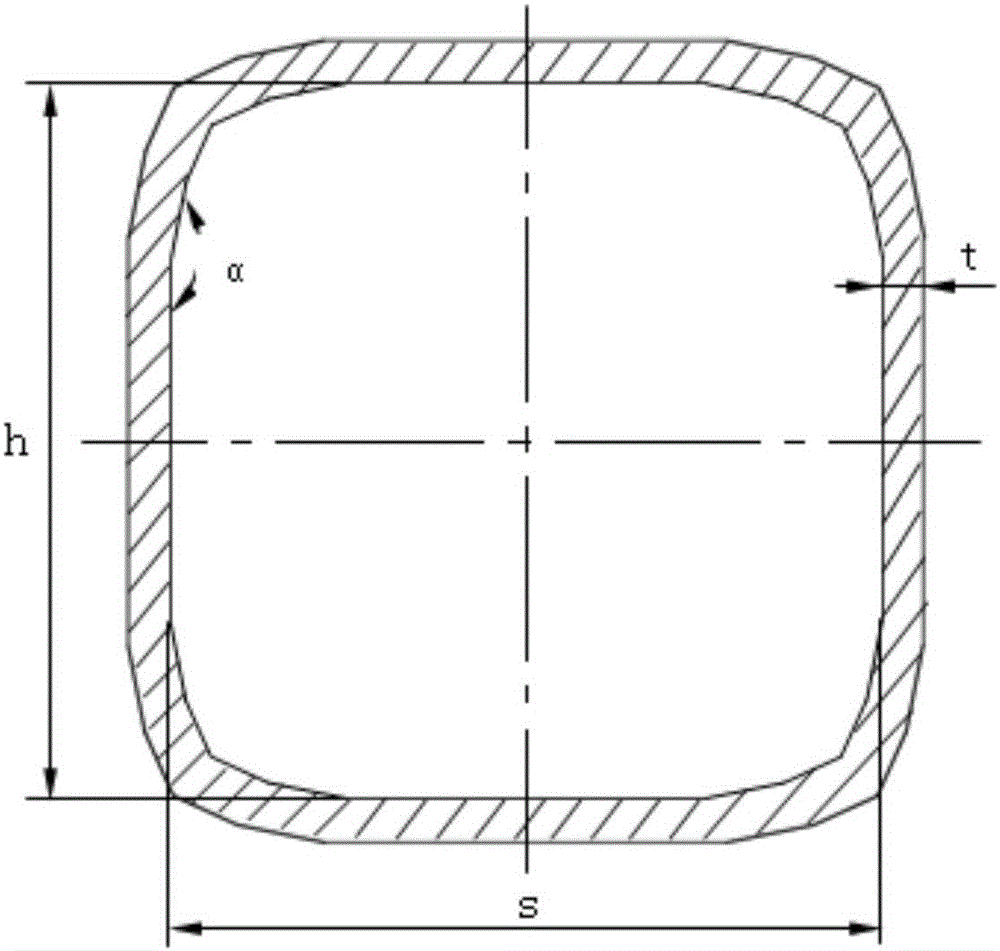

[0048] The chamfering starts at 35mm from the 4th corner of the side wall. There are 3 chamfering sides. The α angle between the chamfering side 1 and the side wall is 159.6°. The included angle α between corner side 3 and 1 and 2 is 155.4°, and the intersecting angle α adopts arc transition, such as Figure 5 As shown, the lengths of chamfered sides 1 and 2 are both 19mm, and the length of chamfered side 3 is 18mm.

[0049] After the copper pipe of the chamfering crystallizer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com