High-efficiency distribution technology of asphalt mixing station

A batching process and high-efficiency technology, applied in batching and batching instruments, chemical instruments and methods, clay preparation devices, etc., can solve the problems of short-term shortage of hot aggregates and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

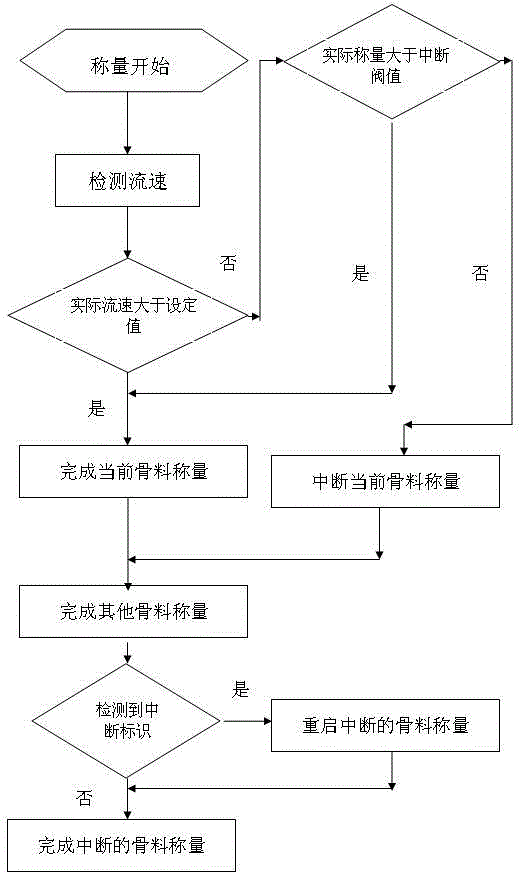

[0024] During the batching process, check the batching condition of the aggregate and judge whether the aggregate is lacking. If the aggregate is normal, continue the batching of the aggregate until the batching is completed; if the aggregate is lacking, temporarily stop the batching of the aggregate. Close the aggregate bin door corresponding to the aggregate, record the weight of the aggregate that has been weighed, and set the batching unfinished mark; continue to weigh other aggregates in the order required by the formula; until the weighing of other types of aggregates is completed, at this time The aggregate silo that is short of material has already stored a certain amount of aggregate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com