Pipe fitting transporter

A technology for transport vehicles and pipe fittings, which is applied in the direction of transportation and packaging, trolleys, motor vehicles, etc. It can solve the problems of affecting transportation efficiency, wasting manpower and material resources, and low transportation speed, and achieves the advantages of improving production efficiency, easy cleaning, and fast transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

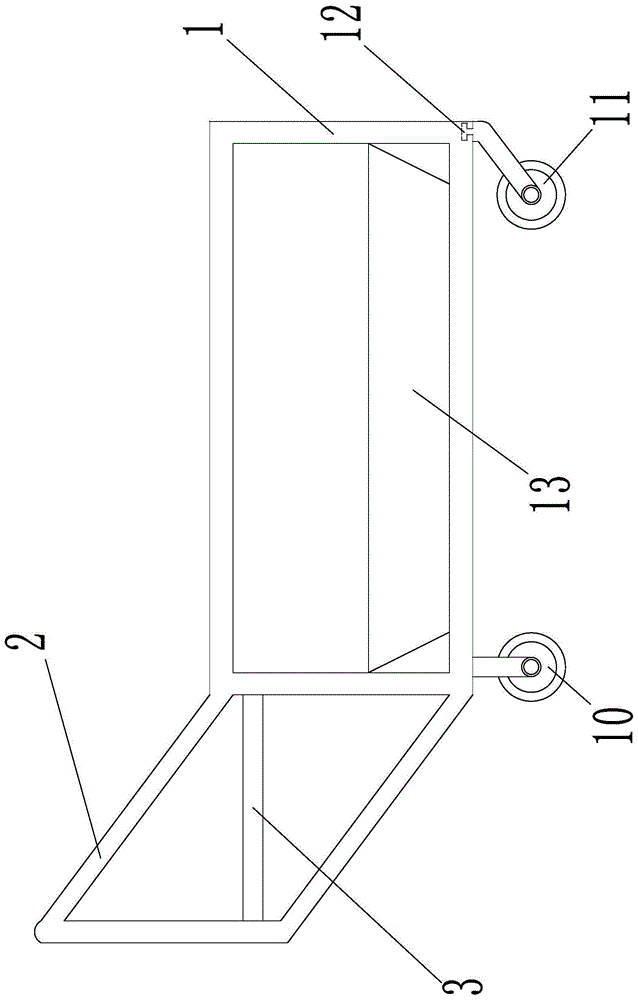

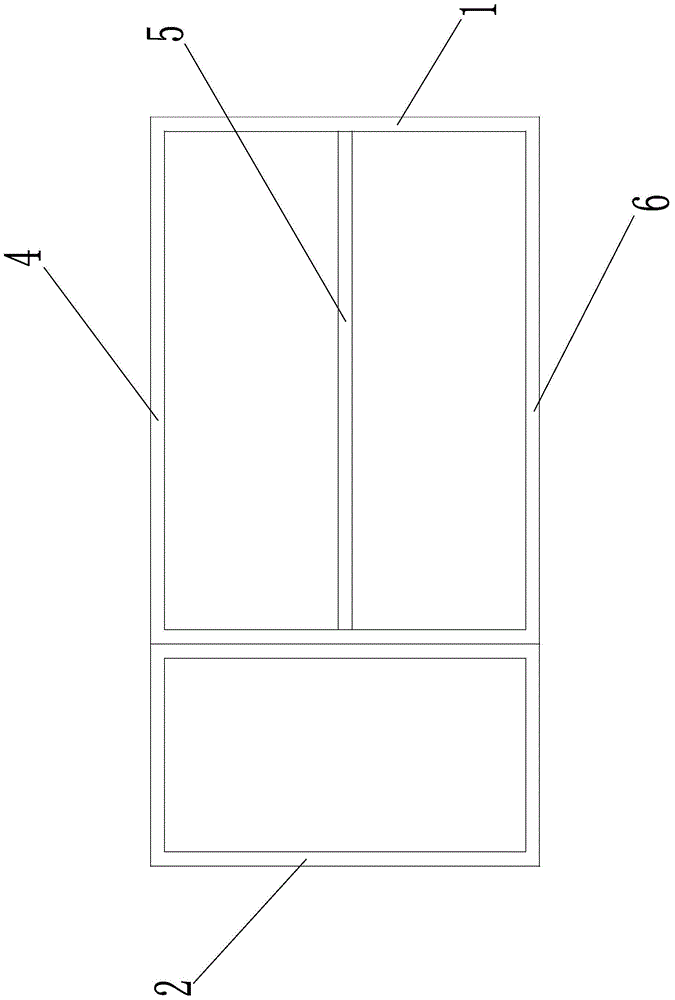

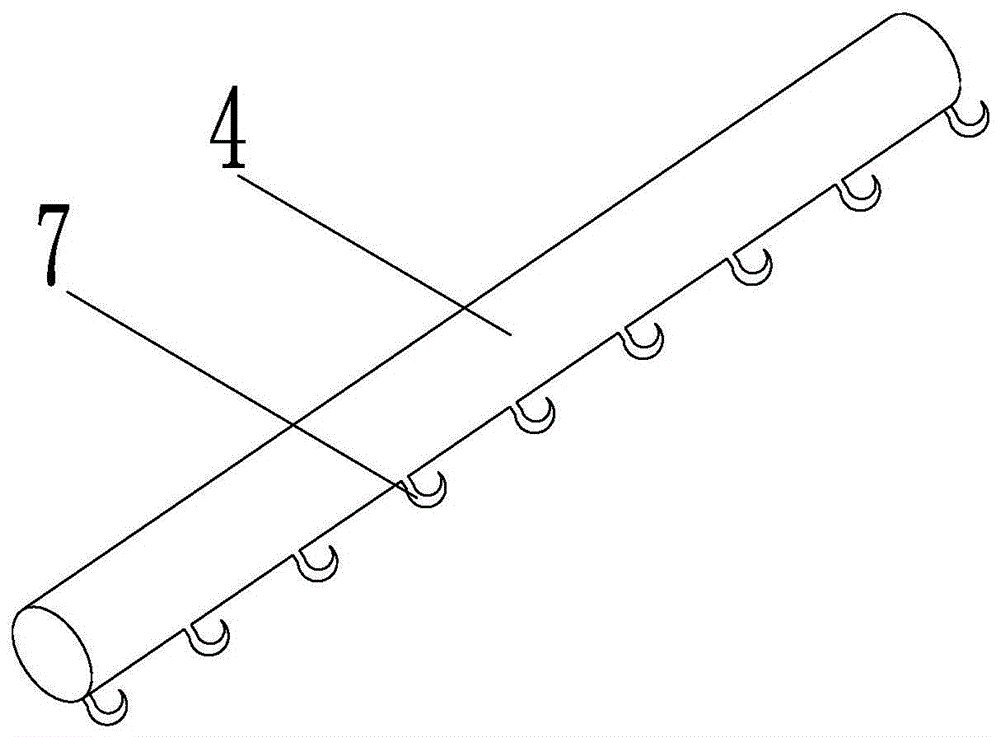

[0013] Such as Figure 1~6 As shown, the technical solution adopted in the present invention is: a pipe transport vehicle, comprising a vehicle body 1 and a push handle 2, the vehicle body 1 and the push handle 2 are welded together through a reinforcing rod 3, and the upper end of the vehicle body 1 is connected from From left to right, a left support column 4, a middle support column 5 and a right support column 6 are installed in turn, and the bottom ends of the left support column 4 and the right support column 6 are each evenly provided with a plurality of hooks 7 towards the inside, and the middle Both sides of the bottom end of the support column 5 are respectively evenly provided with a plurality of hooks 7 towards the outside, between the left support column 4 and the middle support column 5, between the middle support column 5 and the right support column 6, an elastic Net bag 8, two long sides of described elastic net bag 8 are respectively provided with a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com