Insulated corridor type conveyer machine

A conveyor and corridor technology, which is applied in the field of complete modular ground insulation corridor conveyors, can solve the problems of long construction period, easy freezing of materials, high labor costs, etc., and achieves convenient installation and maintenance, reduced labor intensity, and fast installation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

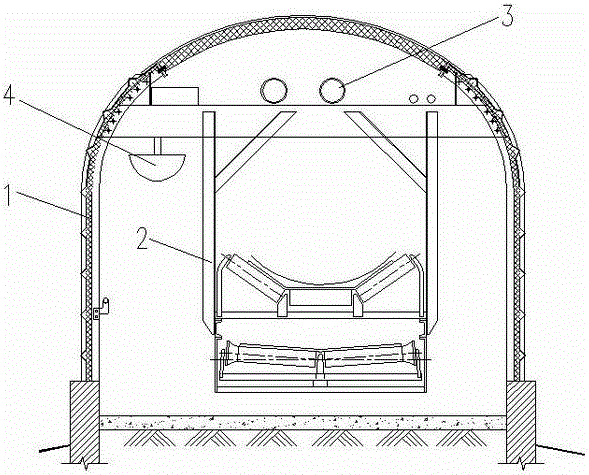

[0019] figure 1 Among them, a heat preservation corridor conveyor, mainly composed of heat preservation corridor 1, conveyor 2, water heating pipe 3 and lighting fixture 4, the cross section of the heat preservation corridor 1 is inverted U shape, and the cross section of the heat preservation corridor 1 is inverted U shape Buckled on the ground, the conveyor 2 is arranged inside the inverted U-shaped heat preservation corridor 1, the water heating pipeline 3 is arranged on the upper part of the conveyor 2 frame, and a plurality of lighting fixtures 4 are arranged on the middle and upper part of the conveyor 2 frame.

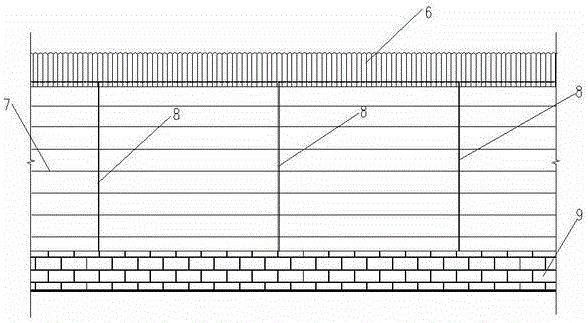

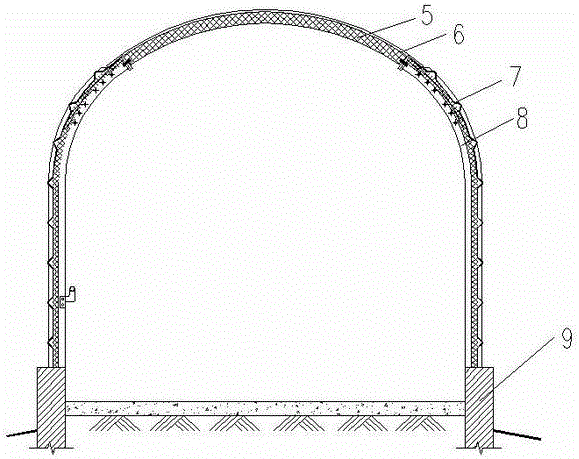

[0020] figure 2 image 3 Among them, the above-mentioned heat preservation corridor conveyor, the heat preservation corridor 1 is mainly composed of heat preservation layer 5, top plate 6, cold-pressed corrugated plate 7, support column 8 and foundation pier 9, and the heat preservation layer 5 traverses The surface is inverted U-shaped, the top of the insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com