Grab and take off device

A technology of stripping device and material column, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as height difference, and achieve the effects of reducing labor intensity, strong practicability, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

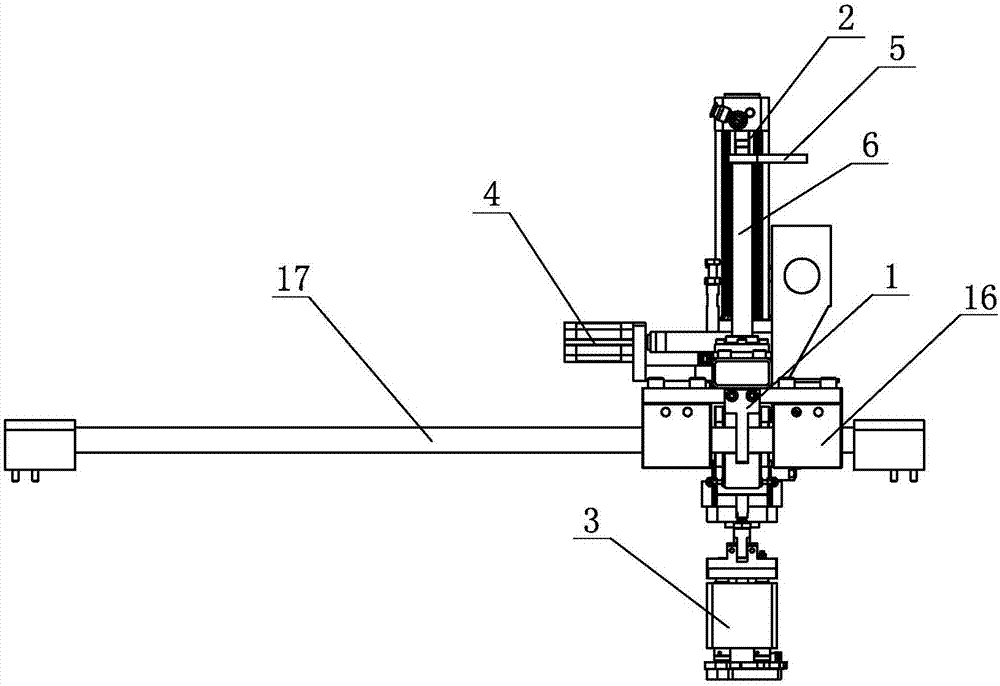

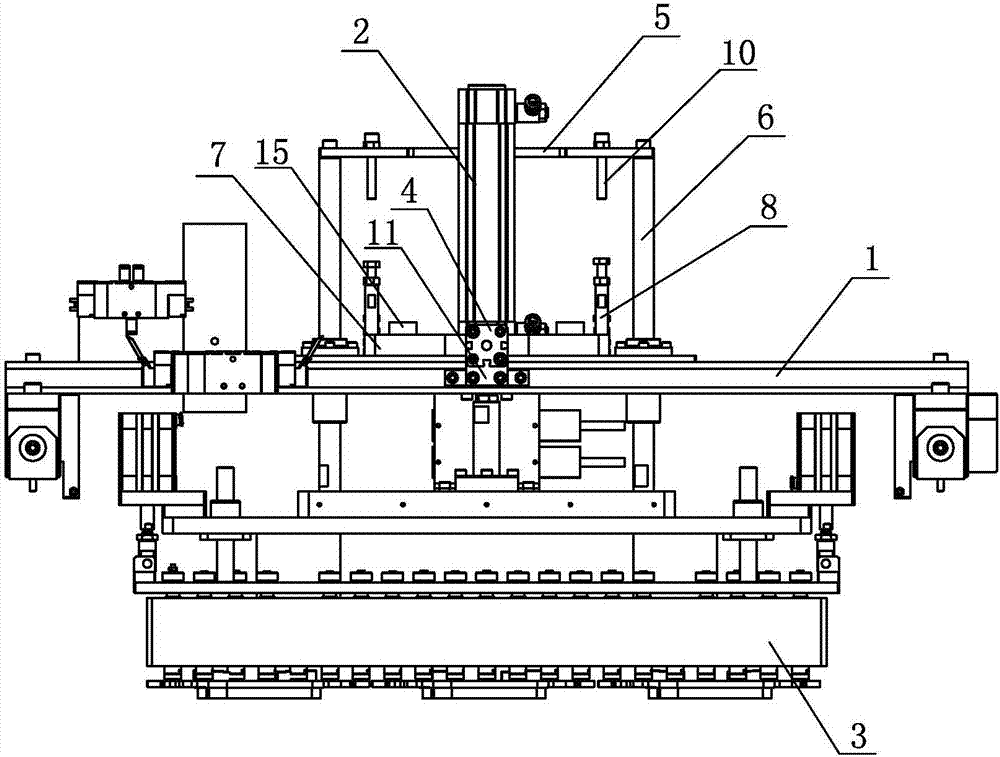

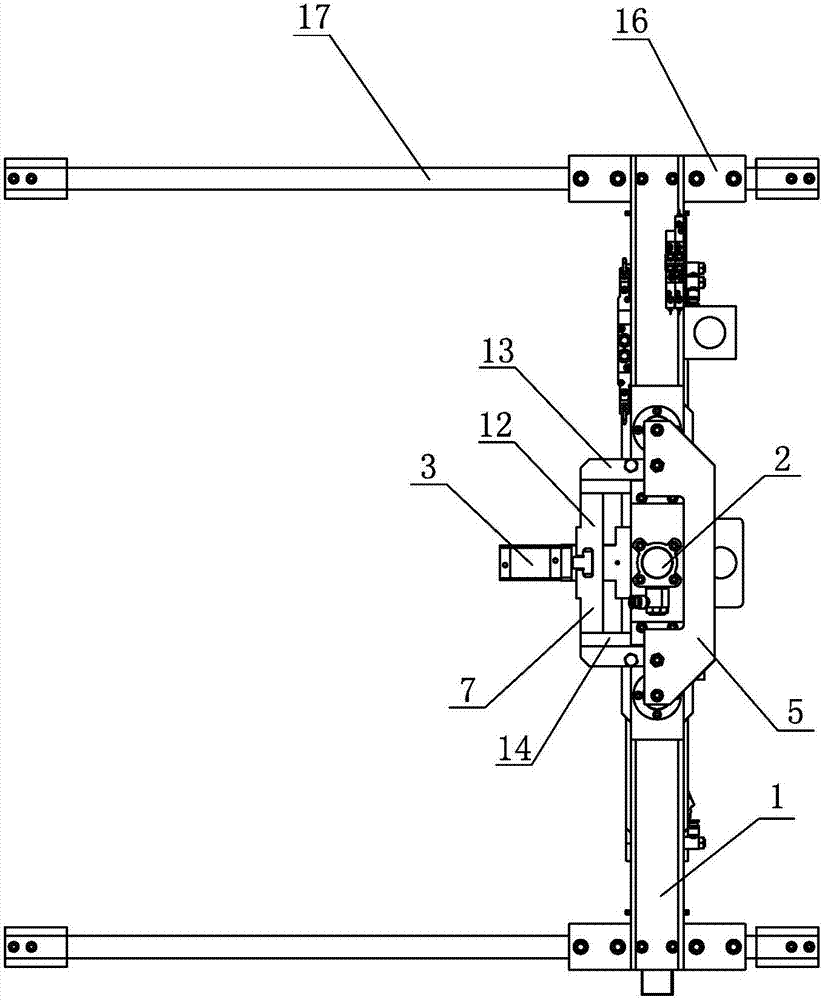

[0031] Embodiment one: see Figure 1~6 Shown, a kind of grasping and stripping device comprises frame, is arranged on the grasping device on the frame, and the two ends of described grasping device slide and are arranged on the described frame through the first telescopic cylinder 16; The frame is provided with two slide bars 17, and the two ends of the material grabbing device are slidingly arranged on the slide bar 17 respectively, and the end of the material grabbing device is connected with the first telescopic cylinder 16, and the material grabbing device Driven by the first telescopic cylinder 16, it slides on the slide bar 17, so that the grabbing device moves between the feeding belt and the machine inlet, so that the grabbing device can grab the brake pads from the feeding belt, and then place the brake pads on the machine entrance.

[0032] see Figure 1~6 As shown, the grasping device includes a support 1, a telescopic cylinder 2 installed on the support 1, a gras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com