Vehicle lifting pin base of railway vehicle and using method for vehicle lifting pin base

A technology of rail vehicles and car pin seats, which is applied in the direction of hoisting devices, lifting frames, etc., can solve problems such as low efficiency and bumps, and achieve the effects of simple structure, saving lifting time, and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

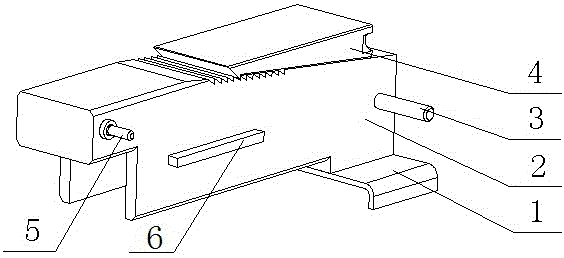

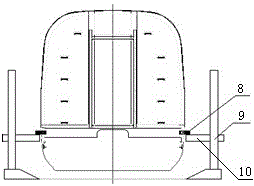

[0025] Attached below Figure 1 to Figure 2 A detailed description of the rail car lift pin seat of the present invention will be given.

[0026] The rail vehicles are respectively provided with rectangular lifting holes 7 on both sides of the car body, and the lifting holes 7 have a certain thickness.

[0027] The rail vehicle lifting pin seat of the present invention includes a buckle plate 1, a base 2, a handle 3, an adjusting wedge 4, a pin 5, and a blocking strip 6.

[0028] The width and height of the base 2 are respectively smaller than the width and height of the vehicle lifting hole 7, and the length of the base 2 is greater than the thickness of the lifting hole 7.

[0029] The two ends in the length direction of the base 2 are called the inner end and the outer end, respectively.

[0030] The gusset plate 1, the base 2, and the handle 3 are welded into one body. The gusset plate 1 is welded to the bottom surface of the outer end of the base 2. Both sides of the gusset plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com