Device and method for removing heavy metal ions in industrial sewage

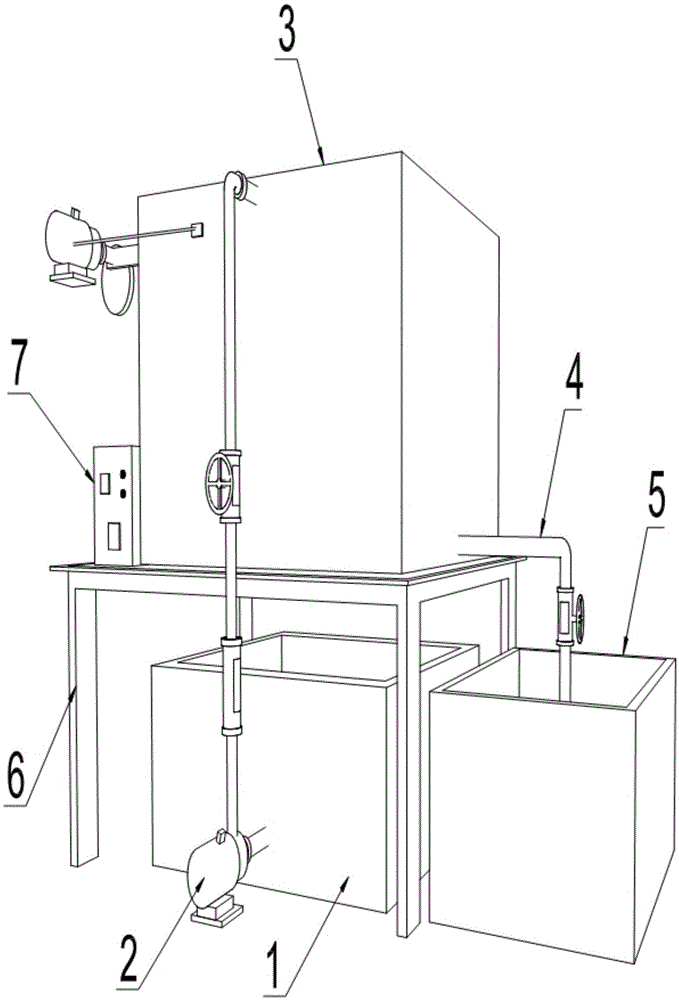

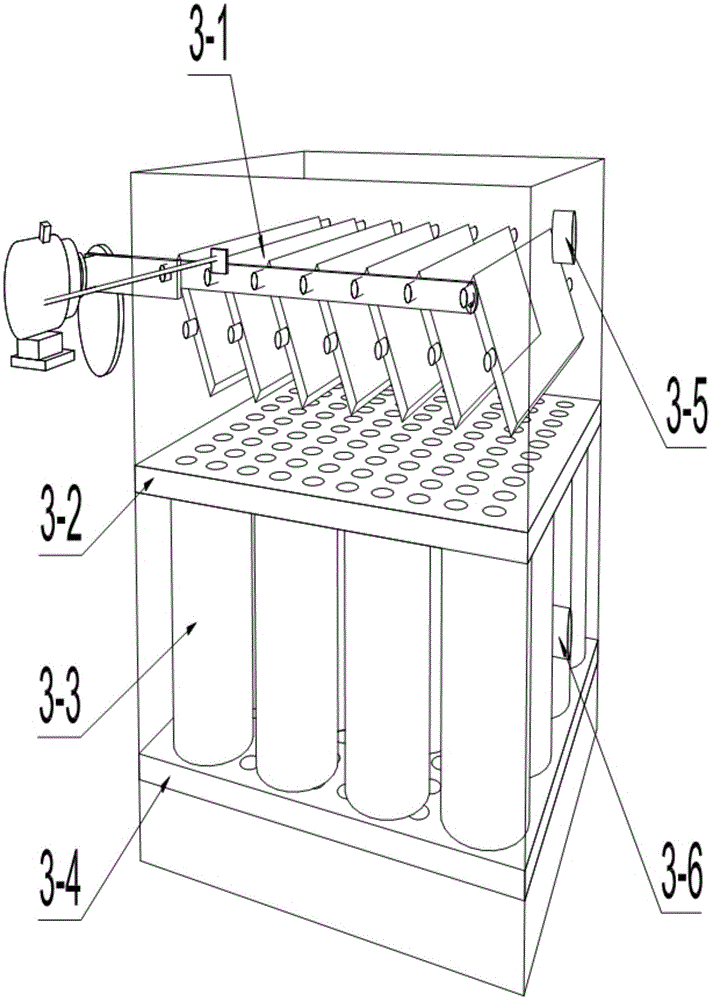

A technology for heavy metal ions and industrial sewage, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of expensive adsorbent, high treatment cost, long process flow, etc. The device structure design is reasonable and compact, the removal rate of heavy metals is high, and the effect of significant improvement is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

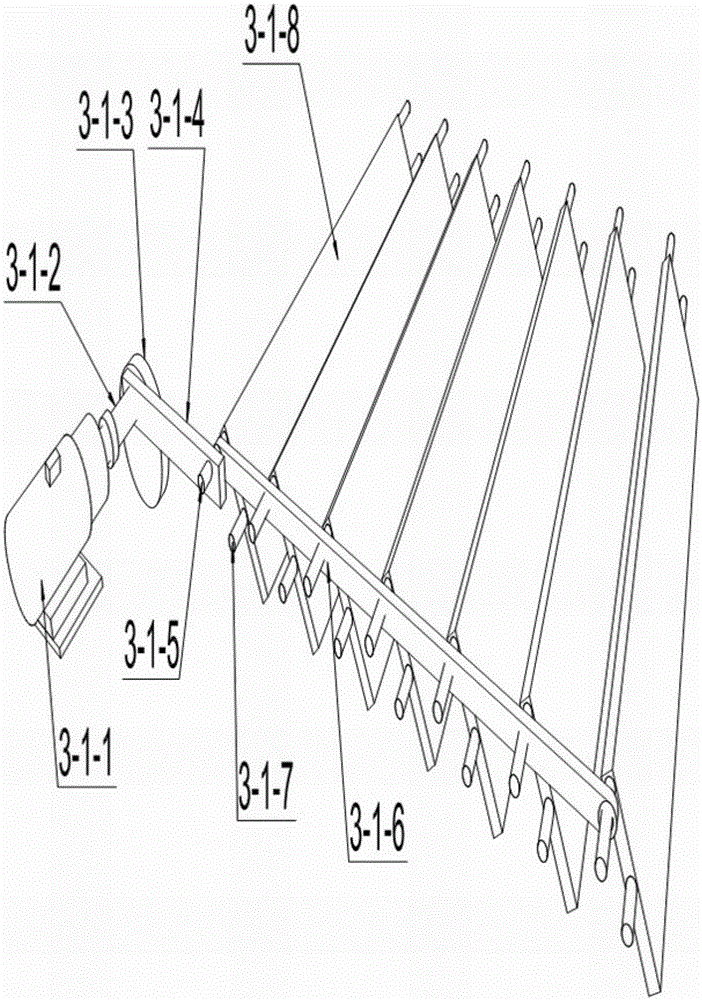

[0063] According to the following steps to manufacture the biofiltration column 3-3-1 of the present invention, and by weight fraction:

[0064] Step 1: Add 1100 parts of ultrapure water with a conductivity of 0.65μS / cm into the reactor, start the stirrer in the reactor at a speed of 195rpm, start the heating pump, and raise the temperature in the reactor to 75°C; add in sequence 36 parts of polypentylene terephthalate, 17 parts of diethyl p-nitrophenyl phosphate, 40 parts of ethyl 2-(2,4-dichloro-5-fluorobenzoyl) acetate, stir until completely dissolved , adjust the pH value to 4.0, adjust the speed of the agitator to 210 rpm, the temperature is 95 ° C, and the esterification reaction is 25 hours;

[0065] Step 2: Take 30 parts of N-(1-cyano-1,2-dimethylpropyl)-2-(2,4-dichlorophenoxy)propionamide, 5-chloro-2-(3 , 5 parts of 4-dimethoxyphenyl)-2-isopropylpentyl cyanide, pulverized, the powder particle size is 900 mesh; add 10 parts of tetrachlorophthalic acid and mix evenly, ...

Embodiment 2

[0070] According to the following steps to manufacture the biofiltration column 3-3-1 of the present invention, and by weight fraction:

[0071] Step 1: Add 1800 parts of ultrapure water with a conductivity of 0.95μS / cm into the reactor, start the stirrer in the reactor at a speed of 270rpm, start the heating pump, and raise the temperature in the reactor to 90°C; add in sequence 78 parts of polypentylene terephthalate, 65 parts of diethyl p-nitrophenyl phosphate, 115 parts of ethyl 2-(2,4-dichloro-5-fluorobenzoyl) acetate, stirred until completely dissolved , adjust the pH value to 8.5, adjust the stirrer speed to 355rpm, the temperature is 160°C, and the esterification reaction is 50 hours;

[0072] Step 2: Take 75 parts of N-(1-cyano-1,2-dimethylpropyl)-2-(2,4-dichlorophenoxy)propionamide, 5-chloro-2-(3 , 60 parts of 4-dimethoxyphenyl)-2-isopropylpentyl cyanide, pulverized, the powder particle size is 1600 mesh; add 90 parts of tetrachlorophthalic acid and mix evenly, spre...

Embodiment 3

[0077] According to the following steps to manufacture the biofiltration column 3-3-1 of the present invention, and by weight fraction:

[0078] Step 1: Add 1145 parts of ultrapure water with a conductivity of 0.6595μS / cm into the reactor, start the stirrer in the reactor at a speed of 211rpm, and start the heating pump to raise the temperature in the reactor to 79°C; add in sequence 66 parts of polypentylene terephthalate, 59 parts of diethyl p-nitrophenyl phosphate, 112 parts of ethyl 2-(2,4-dichloro-5-fluorobenzoyl) acetate, stirred until completely dissolved , adjust the pH value to 4.85, adjust the speed of the agitator to 219rpm, the temperature is 95.16°C, and the esterification reaction is 45 hours;

[0079] Step 2: Take 56 parts of N-(1-cyano-1,2-dimethylpropyl)-2-(2,4-dichlorophenoxy)propionamide, 5-chloro-2-(3 , 55 parts of 4-dimethoxyphenyl)-2-isopropylpentyl cyanide, pulverized, the powder particle size is 978 mesh; add 75 parts of tetrachlorophthalic acid and mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com