Integrated type semi-aerobic stabilizing and integrating system for refuse landfill and application thereof

A landfill and integrated system technology, which is applied in the field of quasi-aerobic stable integrated system of comprehensive garbage landfill, can solve the problems of air pollution around the landfill, slow garbage stabilization rate, and low void ratio of the landfill layer, etc. problems, to achieve the effect of preventing rainwater from entering the landfill layer, achieving rapid stabilization, and weakening the release strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

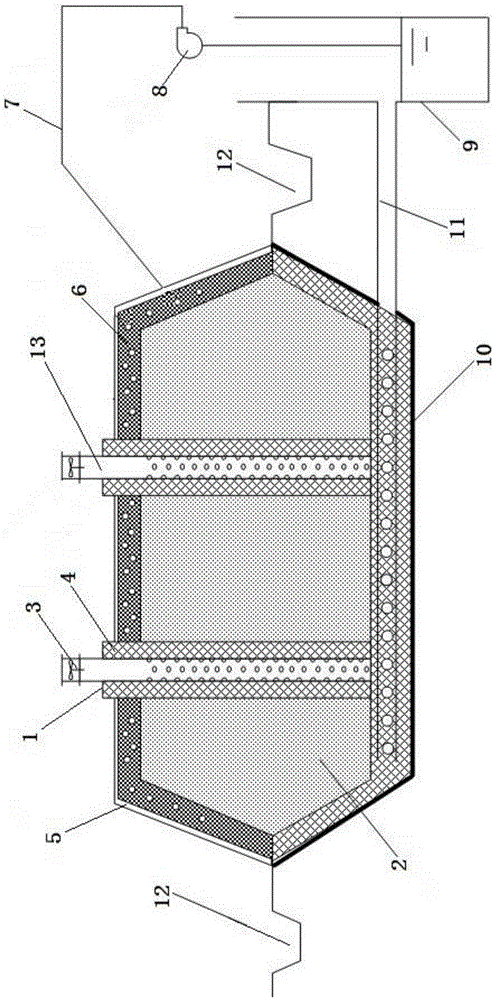

[0035] Such as figure 1 As shown, a comprehensive quasi-aerobic and stable integrated system for waste landfills includes a landfill layer 2, a leachate collection and drainage layer at the bottom of the landfill 2, and a leachate collection and drainage layer The connected leachate collection well 9, the quasi-aerobic landfill gas conduction unit set in the landfill 2, the leachate recharge layer 6 arranged on the upper part of the landfill 2, and the leachate recharge layer 6 and the percolation layer 6 The leachate circulation pipeline connected to the filtrate collection well 9, and the landfill layer 2 is formed by mixing primary domestic waste and domestic waste incinerator slag.

[0036] Among them, the leachate collection and drainage layer is composed of a porous leachate collection pipe 11 arranged at the bottom of the landfill layer 2. The porous leachate collection pipe 11 is connected to the leachate collection well 9, and the porous leachate collection pipe 11 is a ...

Embodiment 2

[0047] In this embodiment, the inner diameter of the porous leachate collection pipe 11 is 650 mm, the opening rate of the upper half of the pipe wall is 15%, and the pore diameter of the percolating hole is 40 mm.

[0048] The diameter of the vertical gas well 1 is 1.6m, the center is a perforated pipe 13, and the outer edge is a steel wire protection net; among them, the inner diameter of the perforated pipe 13 is 175mm, and the wall of the perforated pipe 13 is evenly opened except for 1m at both ends. The aperture is 10mm. The malodorous gas purification packing layer 4 is formed by mixing household garbage incinerator slag, stable household garbage and crushed stone in a mass ratio of 1:1:2.

[0049] The cross-sectional area of the leachate collection well 9 is 4m 2 And the water level of the percolate in the percolate collection well 9 is lower than the percolate collection and drainage layer.

[0050] The rest is the same as in Example 1.

Embodiment 3

[0052] In this embodiment, the inner diameter of the porous leachate collection pipe 11 is 500 mm, the opening rate of the upper half of the pipe wall is 12%, and the pore diameter of the percolating pore is 20 mm.

[0053] The diameter of the vertical gas well 1 is 1.2m, the center is a perforated pipe 13, and the outer edge is a steel wire protection net; among them, the inner diameter of the perforated pipe 13 is 150mm, and the wall of the perforated pipe 13 is evenly holed except for 1m at both ends. The aperture is 15mm. The malodorous gas purification packing layer 4 is formed by mixing household garbage incinerator slag, stable household garbage and crushed stone in a mass ratio of 4:4:1.

[0054] The cross-sectional area of the leachate collection well 9 is 2.5m 2 And the water level of the percolate in the percolate collection well 9 is lower than the percolate collection and drainage layer.

[0055] The rest is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com