Speed-competing tread rubber for motorcycle

A tread rubber and motorcycle technology, applied in the field of tire rubber, can solve the problems of poor grip and handling performance, and achieve the effects of good grip performance, improved wear resistance, and increased friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A motorcycle racing tread compound, characterized in that the components of the raw materials are composed as follows in parts by weight: 100 parts of emulsion polystyrene butadiene rubber, 30 parts of solution polystyrene butadiene rubber, 10 parts of process oil, and high hysteresis carbon black 70 parts, 1 part of stearic acid, 3 parts of zinc oxide, 2 parts of anti-aging agent, 1 part of microcrystalline wax, 2 parts of tert-butyl phenolic resin, 4 parts of tackifying resin, 1 part of sulfur powder, and 2 parts of accelerator.

Embodiment 2

[0027] A rubber material for motorcycle racing treads, comprising 96 parts of EPSBR, 40 parts of SBR, 19 parts of operating oil, 83 parts of high hysteresis carbon black, and 2 parts of stearic acid in parts by weight , 4 parts of zinc oxide, 2.5 parts of antioxidant 4020, 1.5 parts of microcrystalline wax, 4 parts of tert-butylphenolic resin, 6 parts of tackifying resin, 2 parts of sulfur powder, and 2.8 parts of accelerator.

Embodiment 3

[0029] A motorcycle racing tread compound, characterized in that the components of the raw materials are composed as follows in parts by weight: 70 parts of emulsion polystyrene butadiene rubber, 60 parts of solution polystyrene butadiene rubber, 25 parts of operating oil, and high hysteresis carbon black 100 parts, 3 parts of stearic acid, 6 parts of zinc oxide, 4 parts of anti-aging agent, 3 parts of microcrystalline wax, 5 parts of tert-butyl phenolic resin, 7 parts of tackifying resin, 2.5 parts of sulfur powder, and 3.5 parts of accelerator.

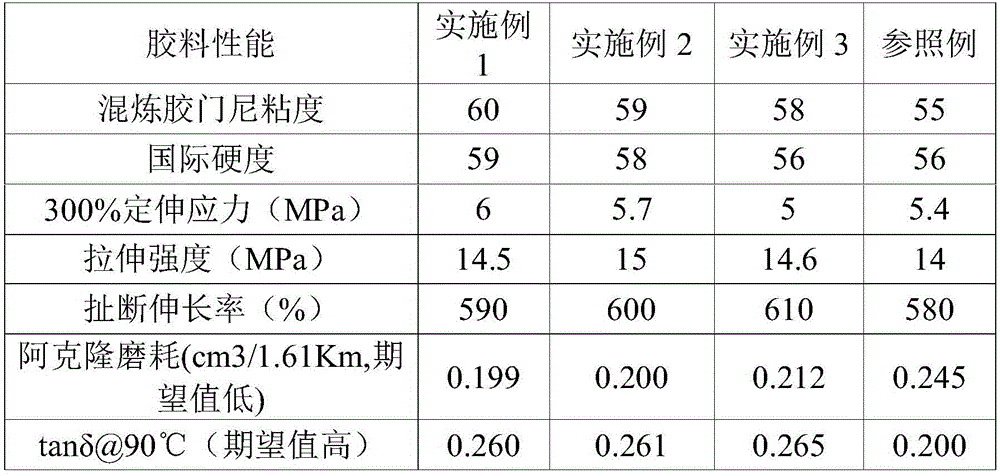

[0030] As shown in Table 1 below, comparing the key performance data of the motorcycle racing tread compound obtained by mixing in the present invention and the reference example, it can be seen that the present invention can not only provide better grip performance and handling performance, but also improve durability grinding performance.

[0031] Table 1 Contrast table of tread rubber material in the present invention and rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com