Low-temperature dehumidifying and drying system for leather

A drying system and low-temperature technology, applied in the field of leather low-temperature dehumidification and drying system, can solve the problems of less air flow and low drying efficiency, and achieve the effects of fast flow speed, high drying efficiency and less exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

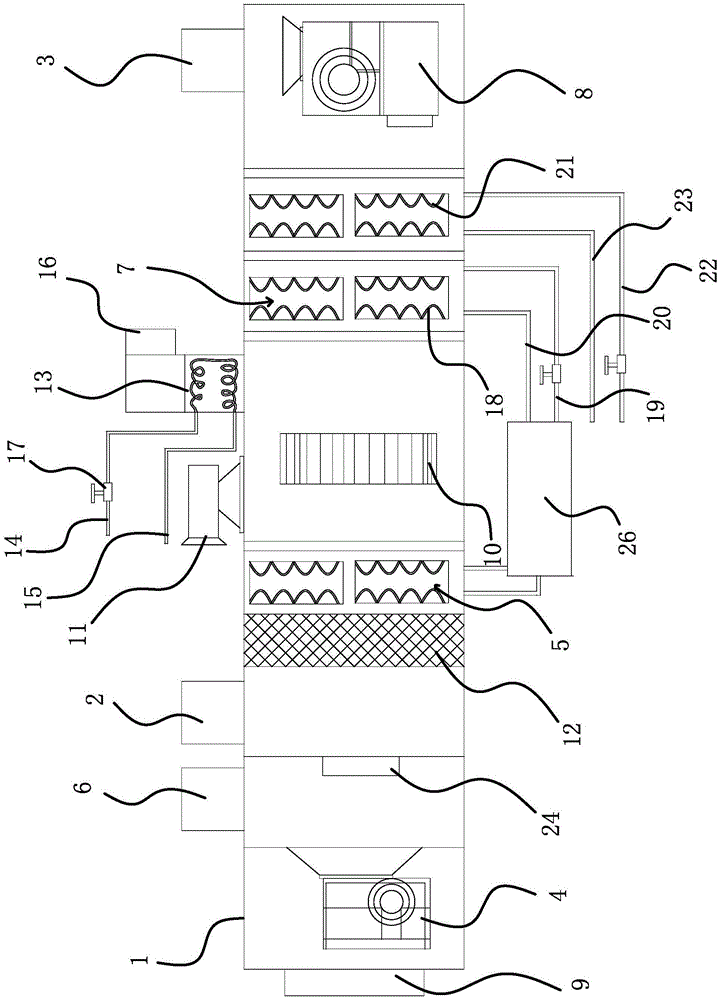

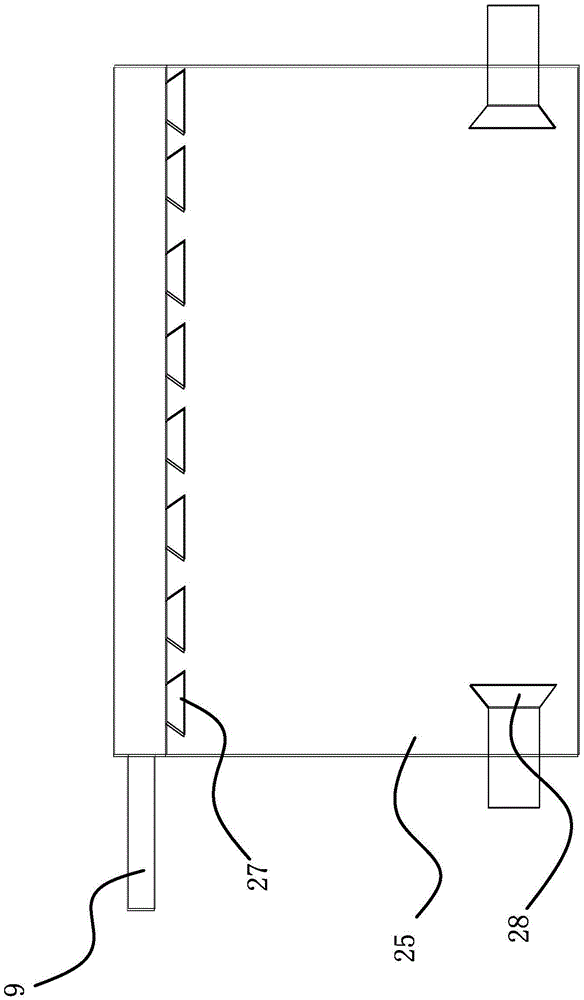

[0024] Such as figure 1 As shown, the low-temperature dehumidification and drying system for genuine leather includes a compression freezer 26, an oven 25 and a cuboid drying box 1. The drying box 1 is composed of aluminum alloy frame strips and double-layer polyurethane foam insulation panels. Drying box 1 left end has the air return pipe 9 that enters for oven 25 return air, and drying box 1 right side has air outlet 3, and the air inlet 2 front side is also provided with the exhaust port 6 that is communicated with drying box 1. The air outlet 6 and the air inlet 2 are all provided with air valves, and the drying box 1 between the air outlet 6 and the air inlet 2 is provided with a dividing plate, and the dividing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com