Anti-collision beam and anti-collision device with anti-collision beam

A technology of anti-collision devices and anti-collision beams, applied in road safety devices, bridges, bridge parts, etc., can solve problems such as small size of anti-collision columns, broken anti-collision steel casings, damage to ship bodies, etc., and achieve good elasticity and plasticity Deformation ability, reliable anti-collision function, and the effect of prolonging the impact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

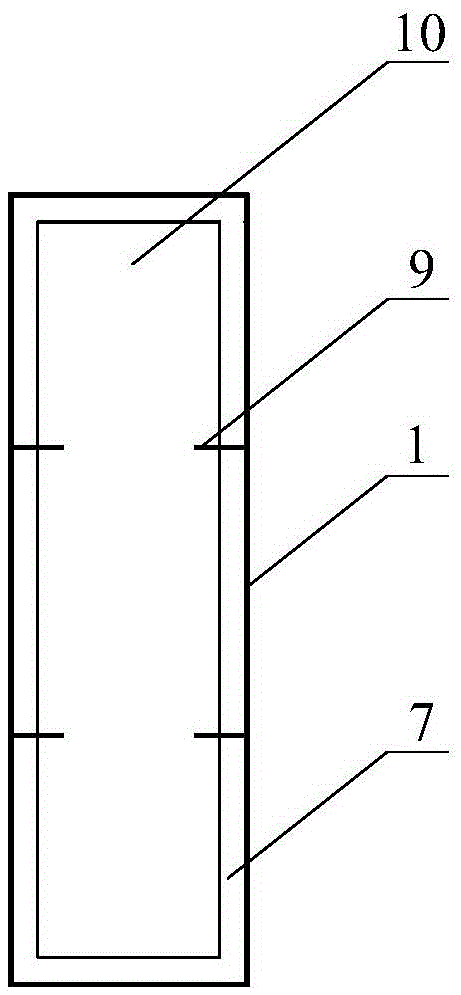

[0038] Embodiment 1, an anti-collision beam is arranged on the periphery of the platform 13

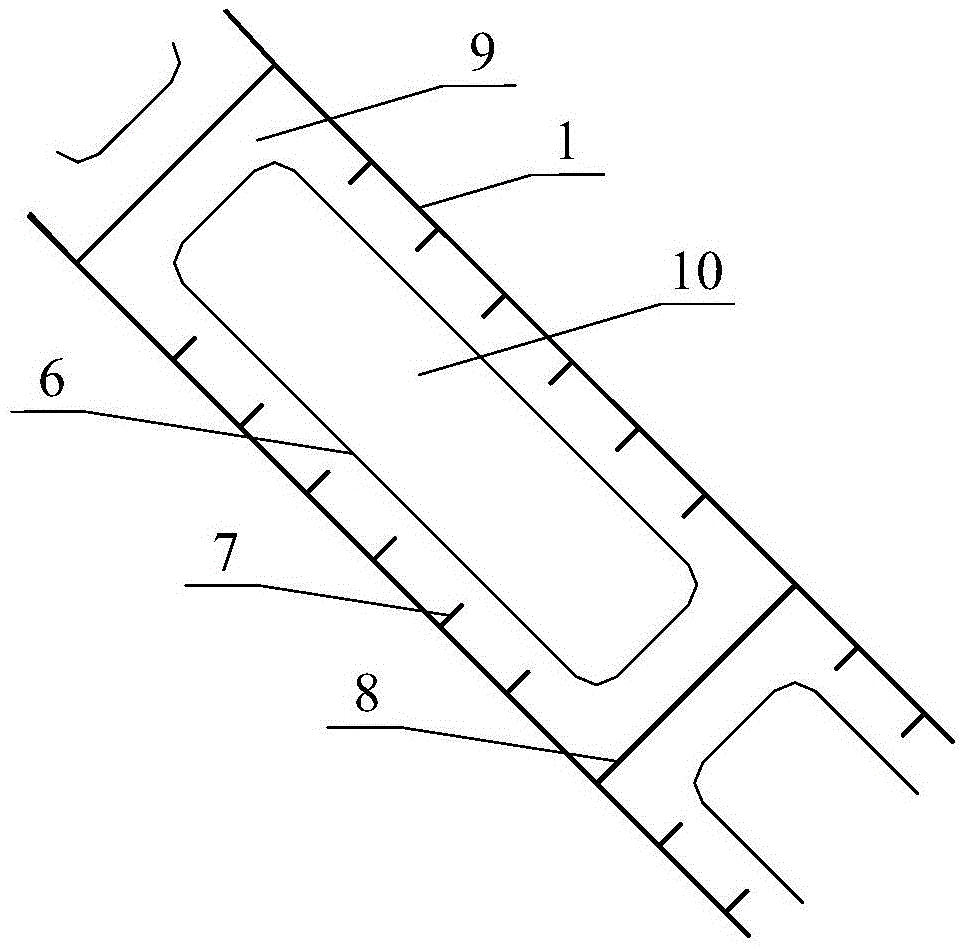

[0039] see Figure 5 As shown, in this embodiment, the anti-collision steel box 14 is first arranged on the periphery of the platform 13, and then the anti-collision beam is connected to the opposite sides of the anti-collision steel box 14 through the connection system 11. In actual use, It is also possible not to set the anti-collision steel box 14 , and connect the anti-collision beam to the opposite sides of the platform 13 through other connecting devices 12 .

Embodiment 2

[0040] Embodiment 2, anti-collision beams are arranged on the periphery of the pier 15

[0041] see Image 6 As shown, in this embodiment, the opposite sides of the pier 15 have been provided with gravity concrete 16, and the anti-collision beam is fixed on the outside of the gravity beam 16 through the connecting system 11. In actual construction, the gravity concrete 16 may not be provided. The anti-collision beams are directly connected to opposite sides of the pier 15 through other connection devices 12 .

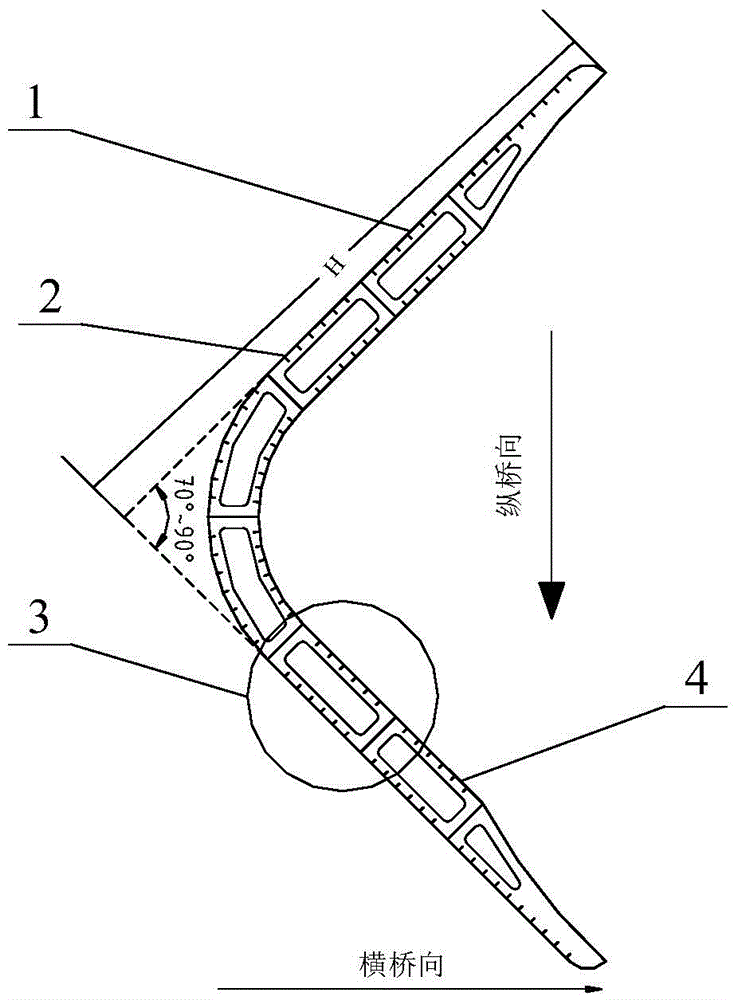

[0042] When the anti-collision device of the present invention is in use, when the anti-collision beam is hit by a ship, on the one hand, the V-shaped structural arrangement can cause the ship to slip along the surface of the anti-collision beam, reducing the kinetic energy exchange between the ship and the pier 15; The composite material filled inside the anti-collision beam has good elastic-plastic deformation ability, which can absorb and dissipate part of the impac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com