Board connection structure

A board connection and B board technology, applied in building construction, construction, etc., can solve problems such as easy to fall off, short service life, increased scrap rate, etc., and achieve the effect of thickness guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

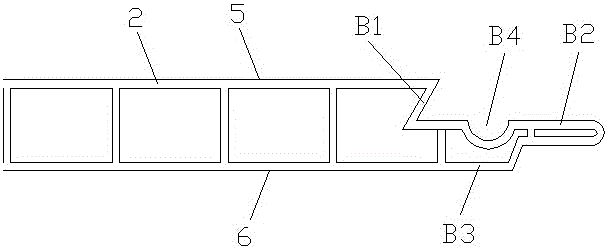

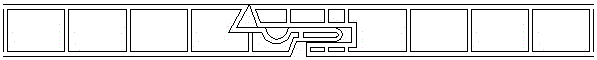

[0044] See Figure 1 ~ Figure 3 , Example 1 includes A board 1 and B board 2.

[0045] After the A board 1 is installed, the front 3 of the A board 1 faces outwards and is exposed, and a decorative structure can be set on the front 3 of the A board 1; the back 4 of the A board 1 faces inward without being exposed, and faces the installation surface of the wall, the bottom plate, etc. .

[0046] After the B board 2 is installed, the front 5 of the B board 2 is exposed outwards, and a decorative structure can be set on the front 5 of the B board 2; the back 6 of the B board 2 faces inward without being exposed, and faces the installation surface such as the wall and the bottom plate .

[0047] A concave butt end is provided on one side of the A board 1. The female butt end includes an upper edge end A1, a mating interface A2 and a lower edge end A3.

[0048] The upper edge end A1 and the lower edge end A3 are fixed on one side of the A plate 1 and can be integrally formed with the A p...

Embodiment 2

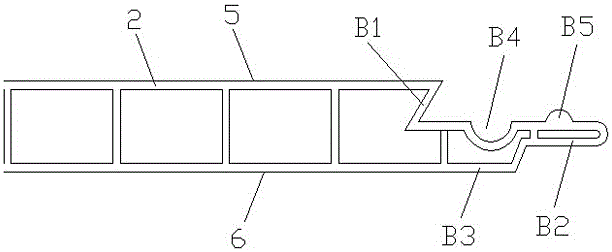

[0064] See Figure 4 ~ Figure 6 In the second embodiment, on the basis of the first embodiment, a clamping block B5 is fixedly arranged on the lower edge butting end B2, and a clamping slot A4 is opened on the upper edge end A1. The clamping block B5 and the clamping slot A4 are matched. When the concave butt end and When the convex butt ends are spliced, the block B5 and the slot A4 are clamped.

Embodiment 3

[0066] See Figure 7 ~ Figure 9 The difference between embodiment 3 and embodiment 1 is that when the female butt end and the male butt end are spliced, the upper edge butt end B1 and the upper edge end A1 are opposite but not in contact, and the gap between the two can be used for installation Construction and decoration materials such as stickers and metal bars. The gap can be formed by keeping the width of the upper edge end A1 unchanged and the upper edge butting end B1 retracting backward, so that the production of the product is simpler and the product firmness is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com