Aluminum formwork system

A technology of aluminum formwork and formwork, which is applied to the preparation of formwork/formwork components, formwork/formwork/work frames, and building components on site. It can solve problems such as mold expansion, mold explosion, and deformation of aluminum formwork, and achieves simplicity. Rapid construction, guaranteed pouring and tamping quality, improved molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

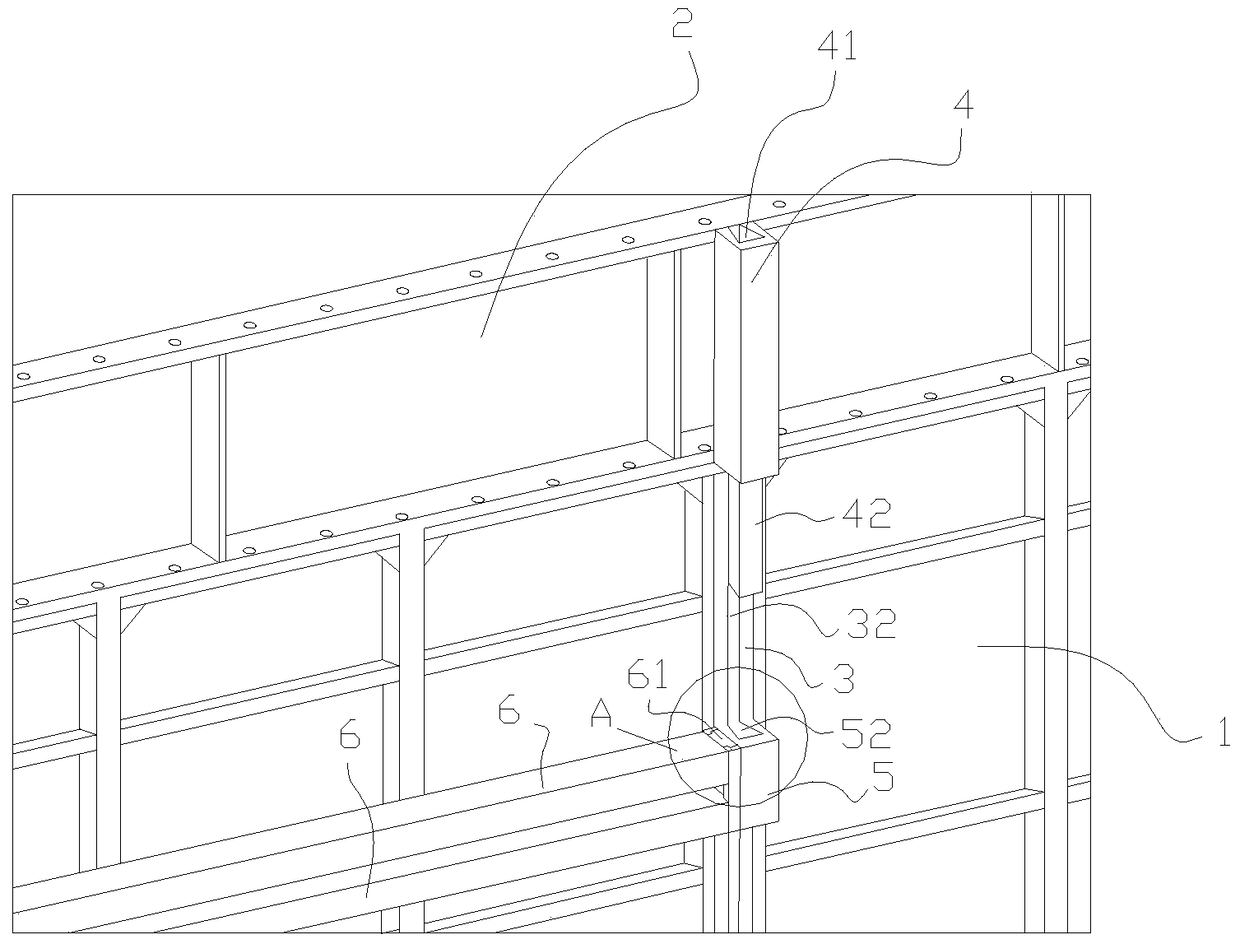

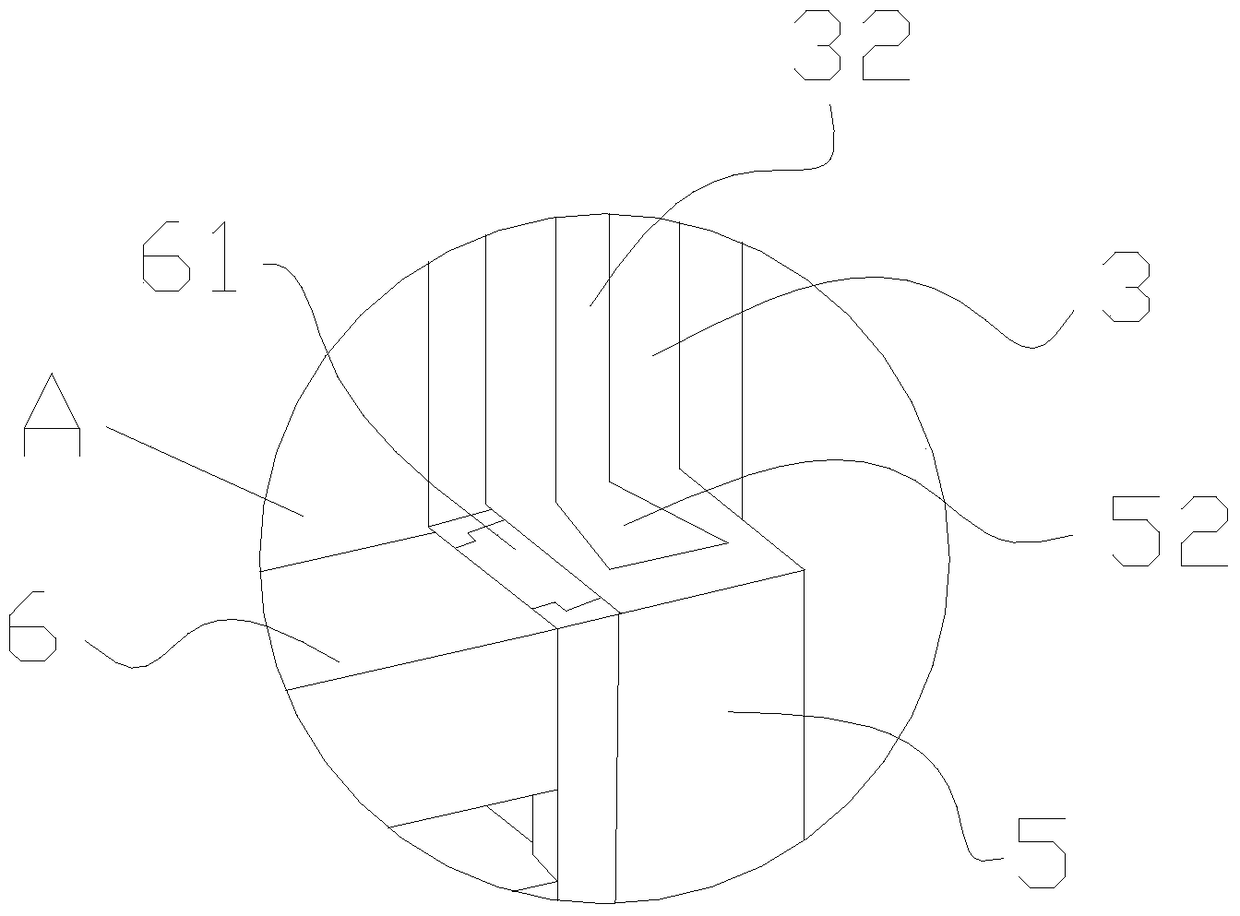

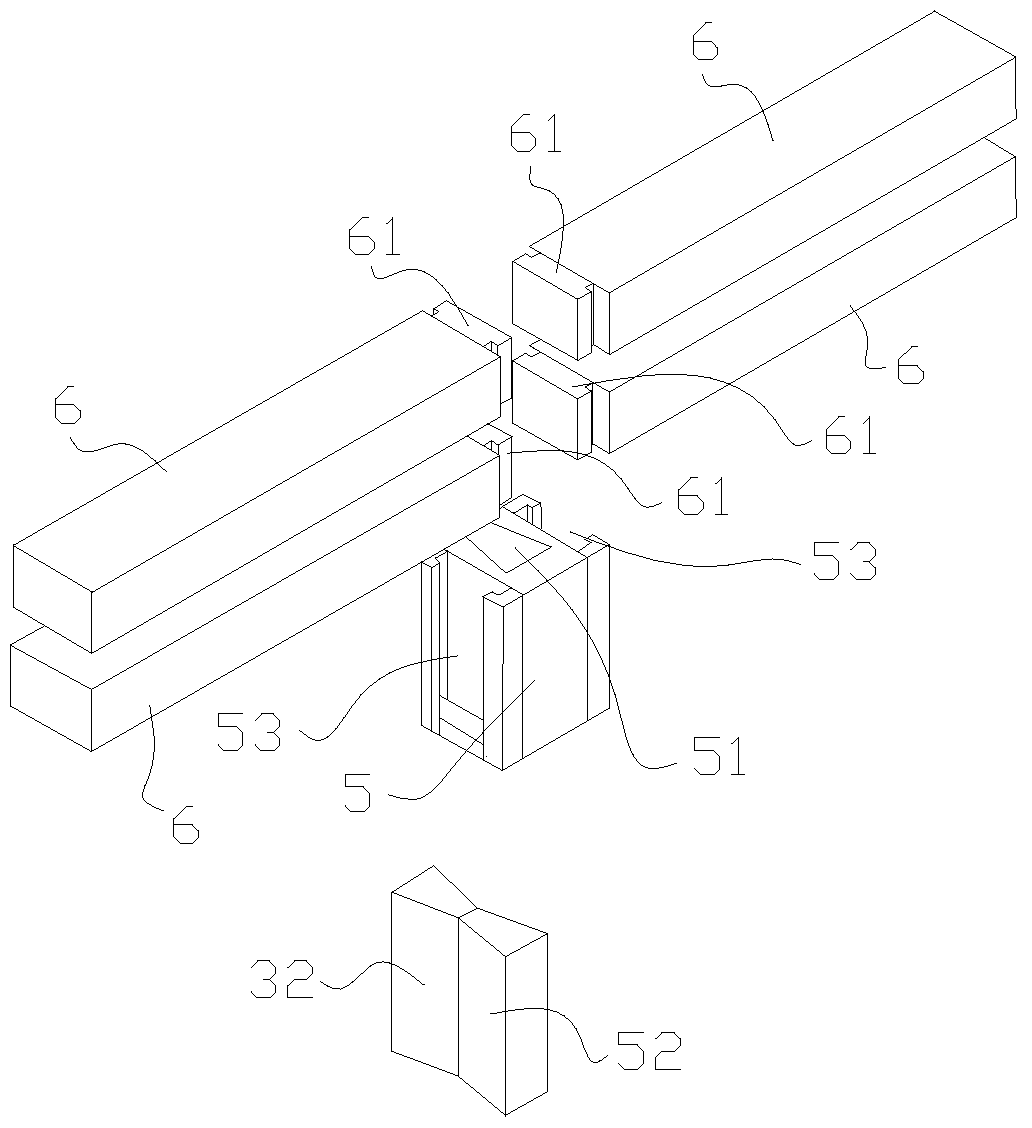

[0021] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0022] refer to Figure 1 to Figure 3 , the embodiment of the present invention provides an aluminum formwork back flute connection node, including a main formwork 1, a first vertical profile flute 3 is vertically arranged along the surface of the main formwork 1, and a longitudinal profile is arranged inside the first vertical profile flute 3 The first card slot 31, the cross section of the first card slot 31 is trapezoidal, the first card slot 31 is embedded with the first embedded slider 32 adapted to the first card slot 31; The back corrugated insert 5 is installed on the top, and the back corrugated insert 5 has a third card slot 51. The cross section of the third card slot 51 is trapezoidal. The third card slot 51 is arranged opposite to the first card slot 31. The third card slot 51 is embedded with a third embedded slider 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com