Turbine-powered double-acting hydraulic oscillating drag-reducing drilling tool

A double-acting, dynamic technology, applied in the direction of vibration drilling, etc., can solve the problems of drilling string support pressure, affecting drilling speed, unable to apply ideal drilling pressure, etc., to prolong service life, reduce total tool length, and reduce contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

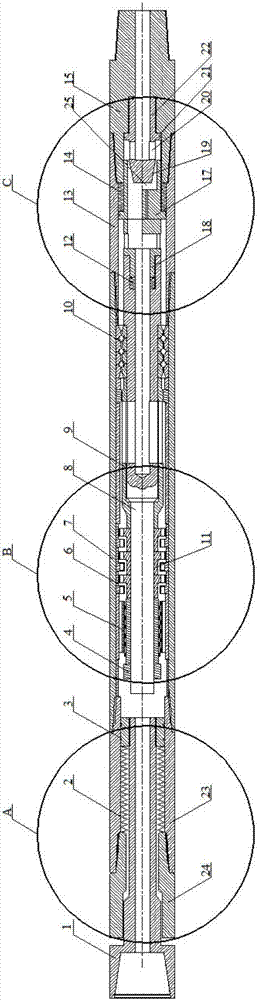

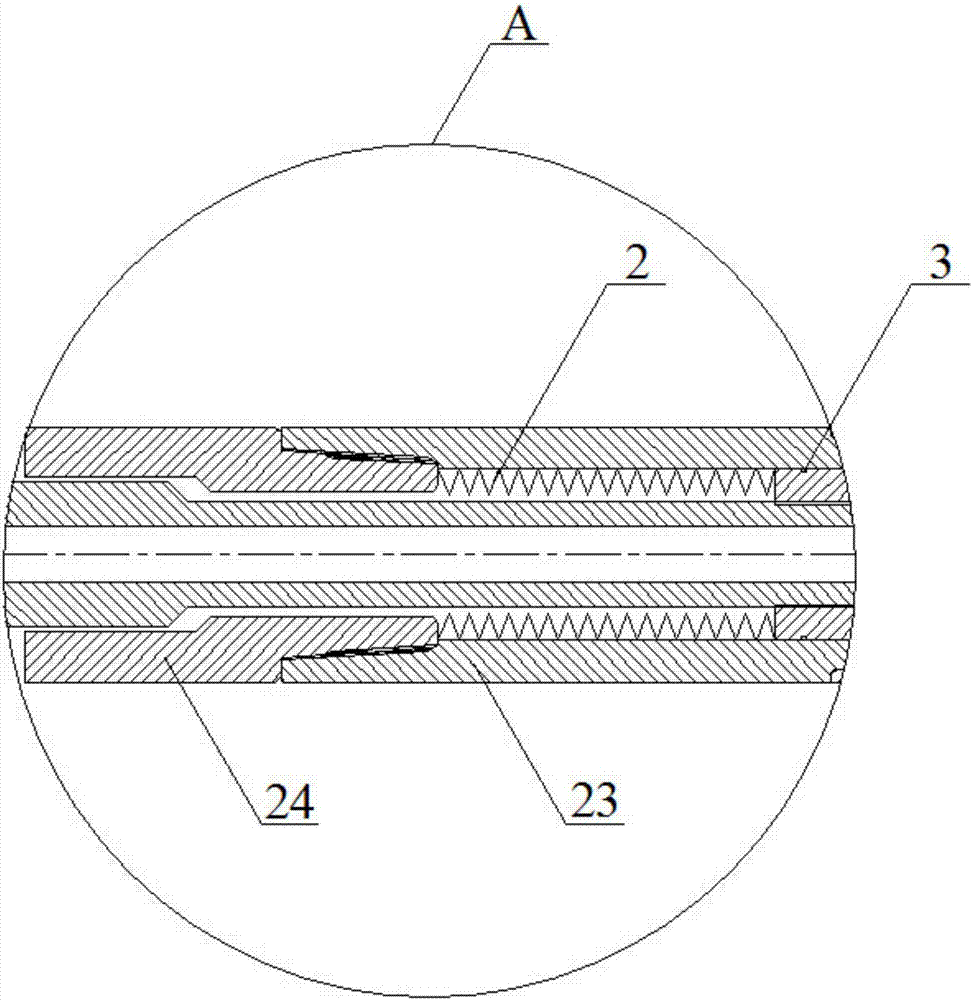

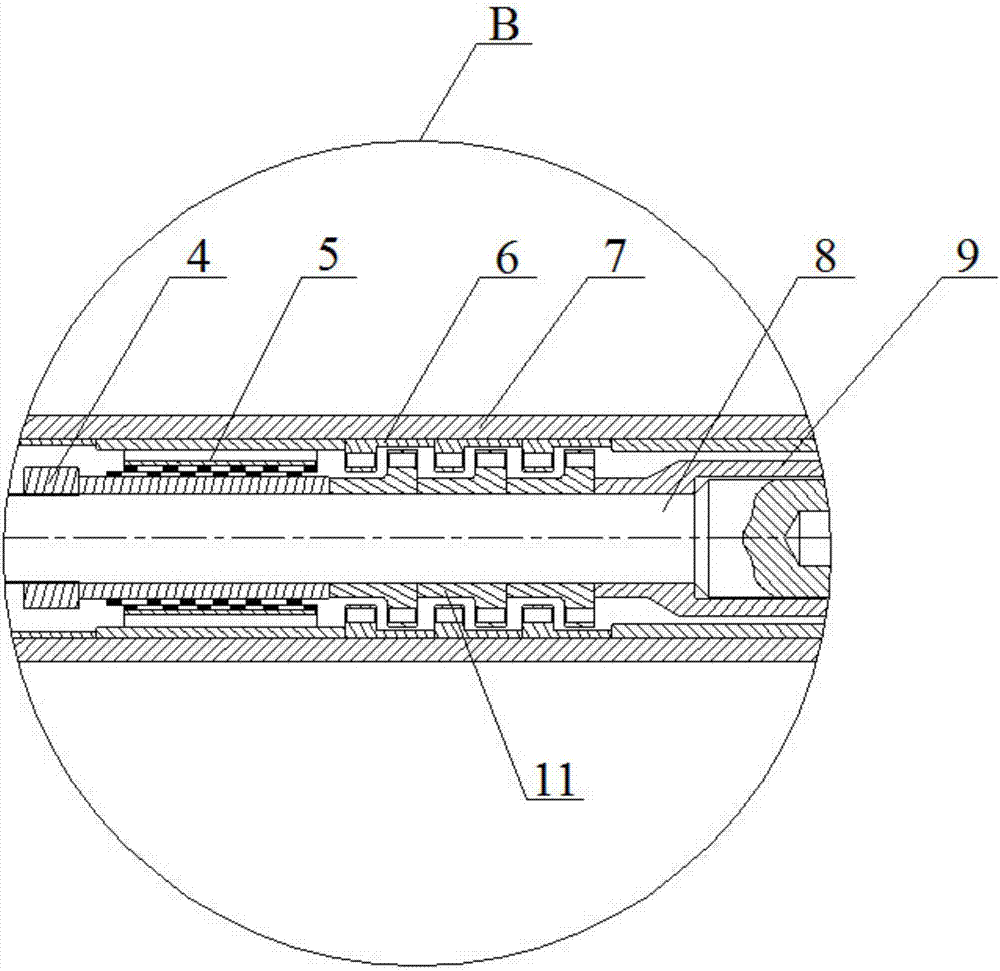

[0023] Below in conjunction with embodiment and its Figure 1-4 The present invention is described in further detail. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0024] Such as Figure 1-4 as shown, figure 1 It is a structural schematic diagram of the turbine-powered double-acting hydraulic oscillation drag-reducing drilling tool of the present invention, Figure 2 to Figure 4 for figure 1 Three partial enlargements of .

[0025] A turbine-powered double-acting hydraulic oscillating drag-reducing drilling tool, comprising a power joint housing 7, a main shaft 8, a slide valve 17, a support seat 15, a vibrating shaft 1, and a vibrating joint housing 23, the main shaft 8 is arranged in the power joint housing 7, The turbine rotor 11 is fixedly installed on the main shaft 8, and the turbine stator 6 is arranged at the position corresponding to the turbine rotor 11 of the power joint housing 7;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com