Roller bit two-way gear sealing structure

A two-way gear and sealing structure technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc., can solve the problems of poor single-stage sealing performance, large contact area, large friction force and friction heat, etc., to ensure strength and sealing performance , Conducive to the formation of lubricating oil film, improve the effect of lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

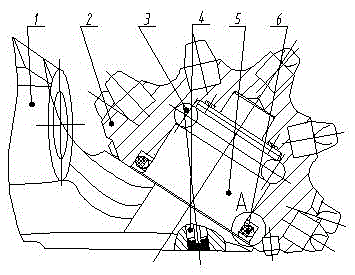

[0010] Such as figure 1 As shown: the claw 1 and the cone 2 are respectively socketed on the bearing 5 through the inner hole of the cone, the steel ball 3 is put into the bearing through the pin hole, and the plug 4 is welded and fixed, and the cone 2 is held by the steel ball 3 on bearing 5. A two-way gear sealing ring 6 is housed between the cone 2 inner hole and the bearing 5 .

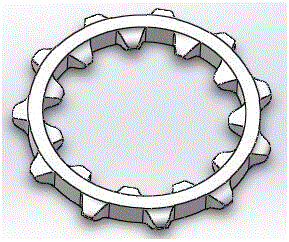

[0011] Such as figure 2 As shown, a two-way gear seal structure of a roller cone bit of the present invention is composed of a cone 2, a bearing 5, and a two-way gear seal ring 6; the body of the two-way gear seal ring 6 is an annular seal ring, and the inside and outside Multiple teeth of the same size are evenly distributed, both sides of the teeth are involute tooth shape, the top surface of the tooth is arc-shaped, the inner and outer teeth are arranged alternately, the inner teeth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com