Stopping method for engine reverse positioning pressure reduction

A technology of engine and decompression mechanism, applied in engine components, engine control, machine/engine, etc., can solve the problems of small engine compression resistance, large engine compression resistance, and excessive reversal angle, so as to reduce starting resistance and improve The effect of rotating speed and prolonging working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

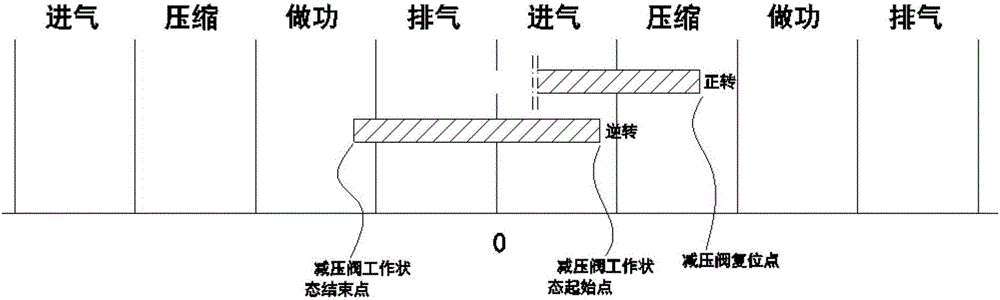

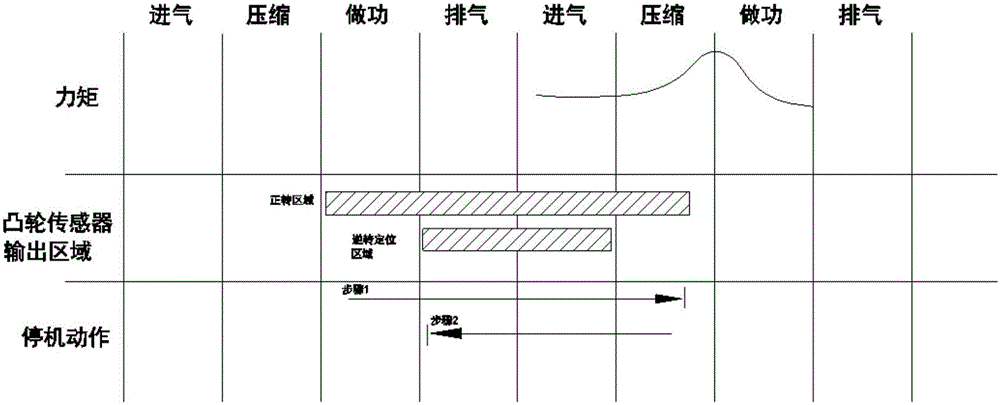

[0035] like figure 1 , figure 2 , Figure 5 , Image 6 As shown, the present invention carries out the shutdown method of reverse positioning decompression when a kind of engine shuts down, and its steps are:

[0036] 1) Before the engine is about to stop, drive the motor forward to make the engine forward to the reset point of the decompression mechanism and then stop;

[0037] 2) The drive motor is reversed, the engine is reversely positioned, the decompression mechanism of the engine enters the position between the starting point and the end point of the decompression state, and the motor drive is stopped.

[0038] This embodiment responds to the control when the engine is stopped. During the process of each engine flameout to complete stop, the reverse positioning method is carried out, so that the engine is always in a depressuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com