A Burner Used to Study Oscillating Combustion Characteristics of Metal Particles

A metal particle and oscillating combustion technology, which is applied in the direction of machines/engines, jet propulsion devices, rocket engine devices, etc., can solve the problem of damage to the engine combustion chamber, engine performance problems, strong destructive combustion instability, and high complexity Randomness and other issues to achieve the effect of improved security and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Battery of the present invention adopts outdoor liquefied gas tank to provide fuel, as Image 6 As shown, the air pipe is connected to the fuel injection port 16 of the metal joint 2, and the gas, oxidizer and dilution gas can be respectively delivered to the micro burner only by rotating the button switch on the gas tank.

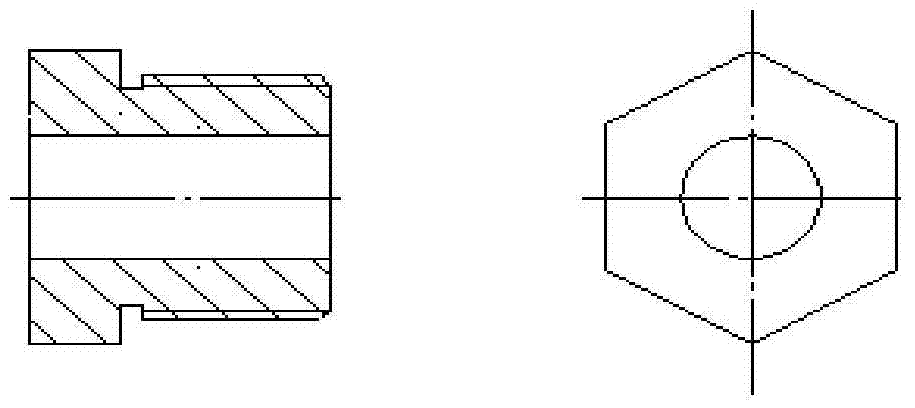

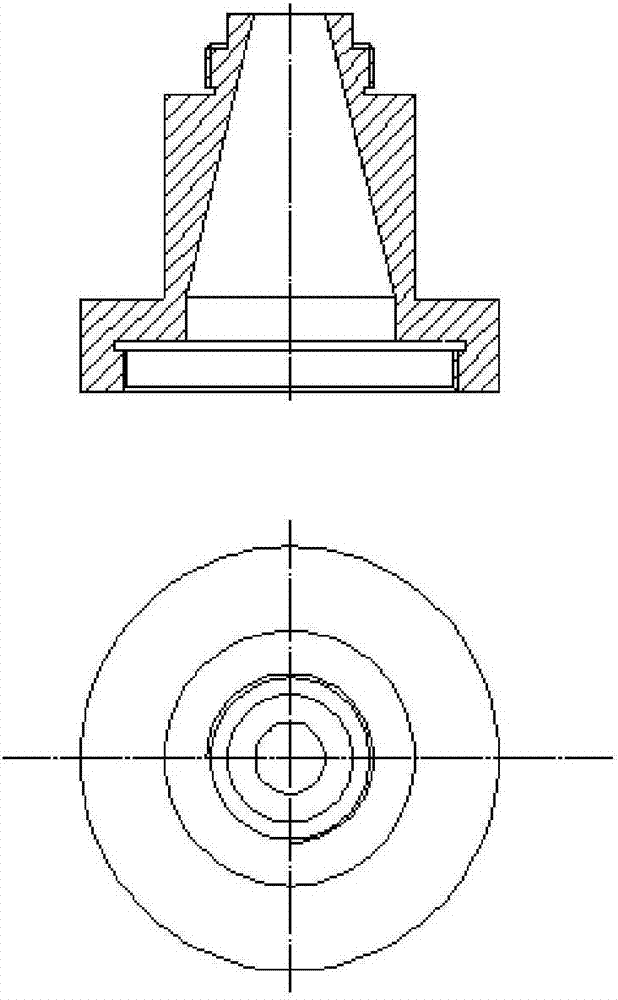

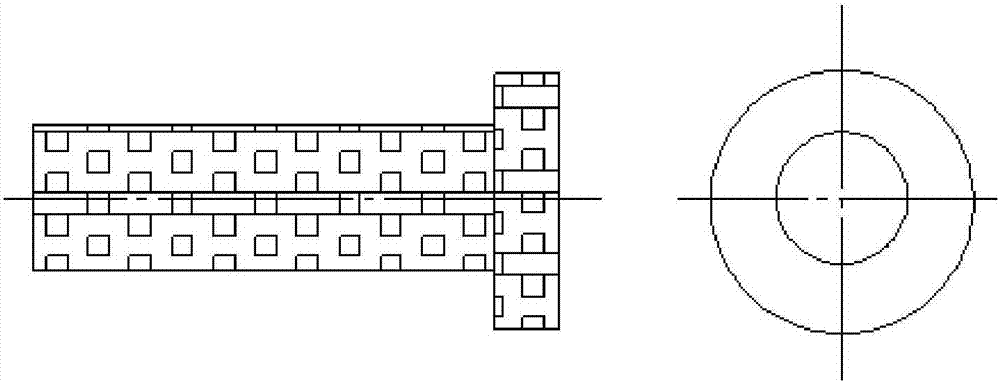

[0031] Burners for studying the oscillating combustion properties of metal particles, such as Image 6 Shown includes: trumpet 1, metal joint 2, porous medium 3, sealing joint 4, stainless steel tube 5, metal sleeve 6, flame stabilizer 7, metal particle delivery port 8, upper half quartz tube 9, cross bar 10, bracket sleeve 11. Bracket 12, base 13, horn cover 14, hole joint 15, injection port 16, graphite gasket 17, sound pressure sensor interface 18, high temperature resistant gasket 19.

[0032]Connection relationship: the speaker 1 is fixedly connected to the speaker cover 14, the speaker cover 14 is connected to the hole joint 15 through thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com