Device used for waste incineration

A technology for incinerating garbage and combustion chamber, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of incomplete combustion and unsatisfactory incineration treatment effect, and achieve the effect of saving resources, high energy utilization rate, and improving cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

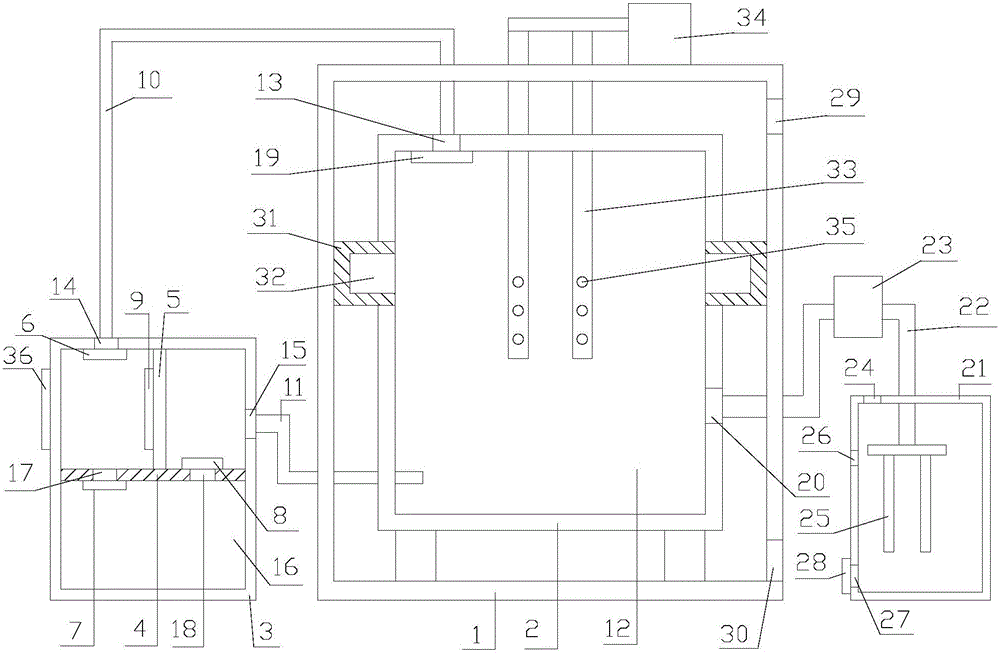

[0041] refer to figure 1 :

[0042] A device for incinerating garbage proposed by the present invention includes an outer shell 1, an inner shell 2, a box body 3, a partition plate 4, a moving piece 5, a first one-way film 6, a second one-way film 7, a second one-way film Three one-way membranes 8, magnetostrictive film 9, coil 36, first connecting pipe 10, second connecting pipe 11, filter screen 19, water tank 21, third connecting pipe 22, exhaust fan 23, multiple cooling pipes 25, A valve 28, a plurality of connecting columns 31, a plurality of intake pipes 33, and a blower 34.

[0043] The inner casing 2 is placed inside the outer casing 1, the interior of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com