Automobile self-inspection method and detection system

A self-inspection and automobile technology, which is applied in the direction of vehicle testing, measuring devices, machine/structural component testing, etc., can solve the problems of unreachable popularization and self-inspection, achieve convenient, fast and accurate detection methods, improve accuracy, and improve Detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

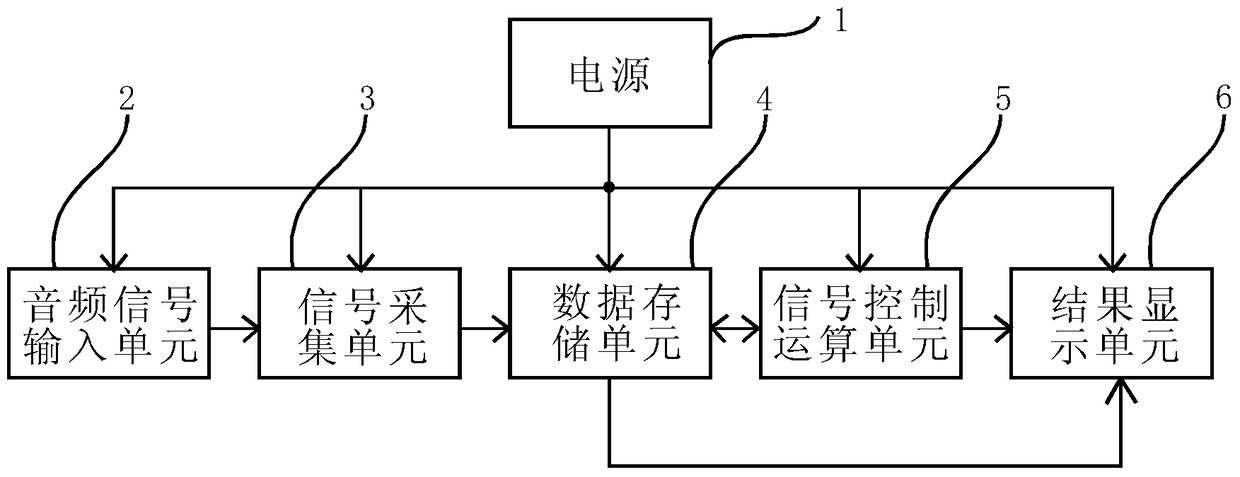

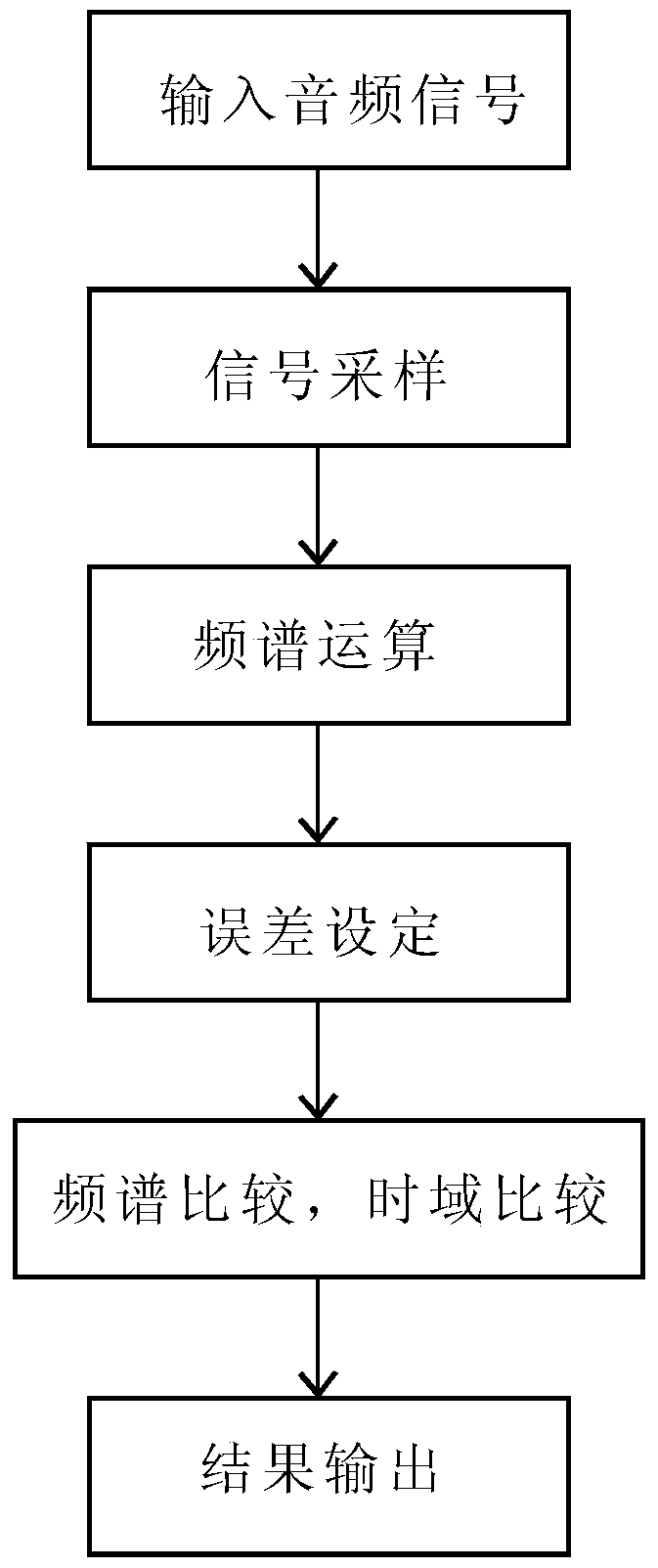

[0029] Take the self-detection of abnormal noise in a car engine during driving as an example.

[0030] step 1,

[0031] First, start the common engine fault signals, standard and normal cars and car engines to be inspected. The running sound of the engine can be input in real time by audio signals such as MEMS sound sensors to convert the audio signals into electrical signals. The signal acquisition unit 3 will The electrical signal is sent for sampling processing (if the accuracy is to be changed, the sampling frequency and quantization number of the selected signal acquisition unit can be changed according to actual needs), the analog signal is converted into a digital signal, and the above data is stored in the data storage unit 4.

[0032] Step 2.

[0033] Tools such as computers or FPGAs or single-chip microcomputers or virtual instruments can perform spectrum analysis and comparison of spectrum characteristics and time-domain characteristics. Therefore, the signal operation con...

Embodiment 2

[0039] Take the common abnormal noise detection of drive shaft and drive axle as an example.

[0040] step 1,

[0041] First, the common transmission shaft fault signal is input by sound sensors such as MEMS and converted into electrical signals. At the same time, the standard normal car and the car to be inspected are started. When the car is slowing down or increasing the speed and turning, the transmission shaft The running sound emitted by related components can be input by the MEMS sound sensor in real time to convert the audio signal into an electric signal, and the signal acquisition unit 3 sends the above electric signal for sampling processing (if the accuracy is to be changed, the accuracy can be changed according to the actual It is necessary to change the sampling frequency and the number of quantization bits of the selected signal acquisition unit), convert the analog signal to a digital signal, and store it in the data storage unit 4.

[0042] Step 2.

[0043] The signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com