Wire harness fatigue testing device and testing method

A technology of fatigue testing and testing methods, which is applied in the direction of measuring devices, using repeated force/pulsation force to test the strength of materials, instruments, etc., can solve the problems of poor test consistency and low test accuracy, and achieve good practicability and high test efficiency , Test consistency and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

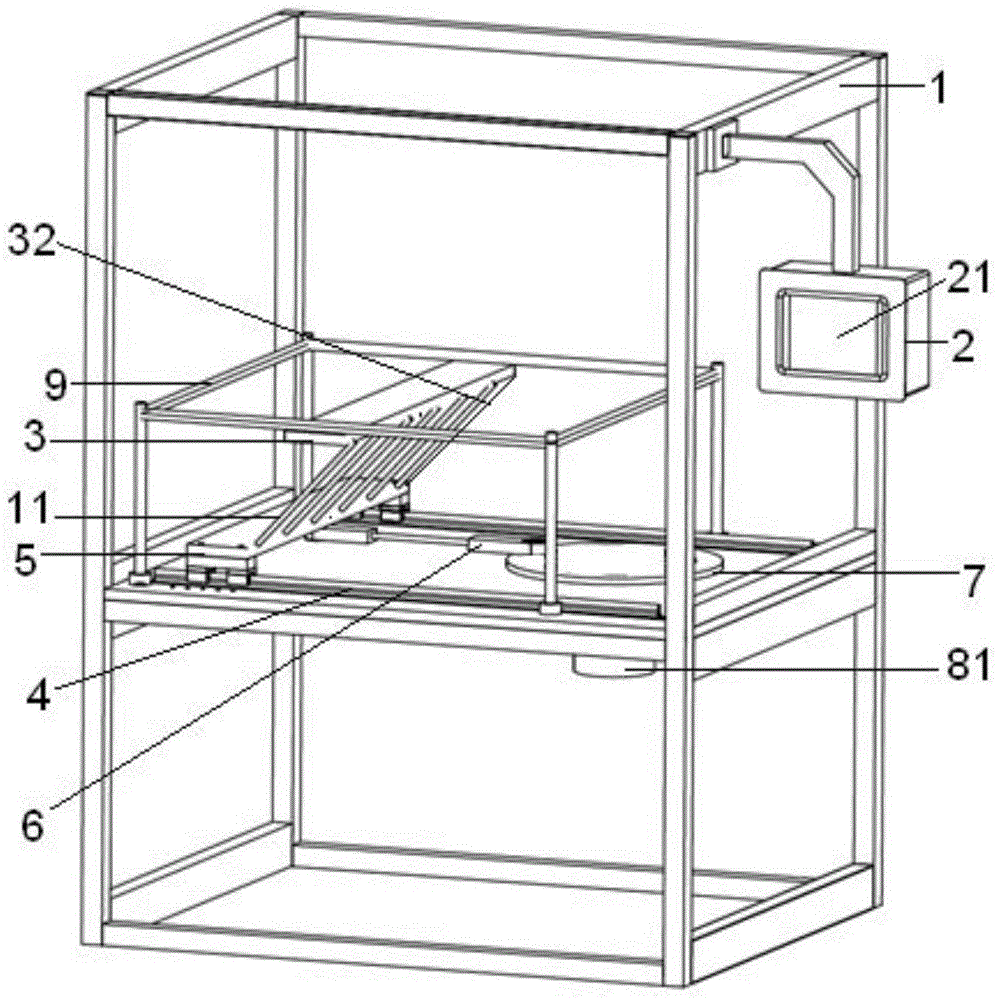

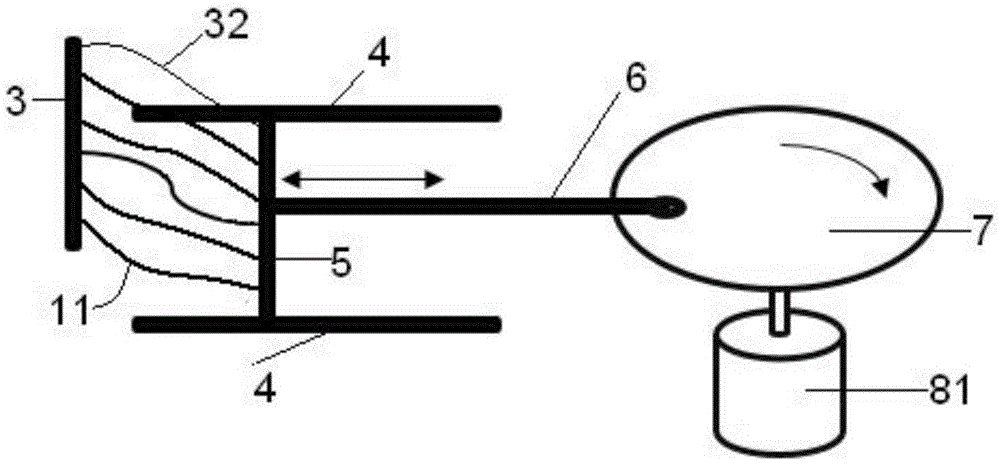

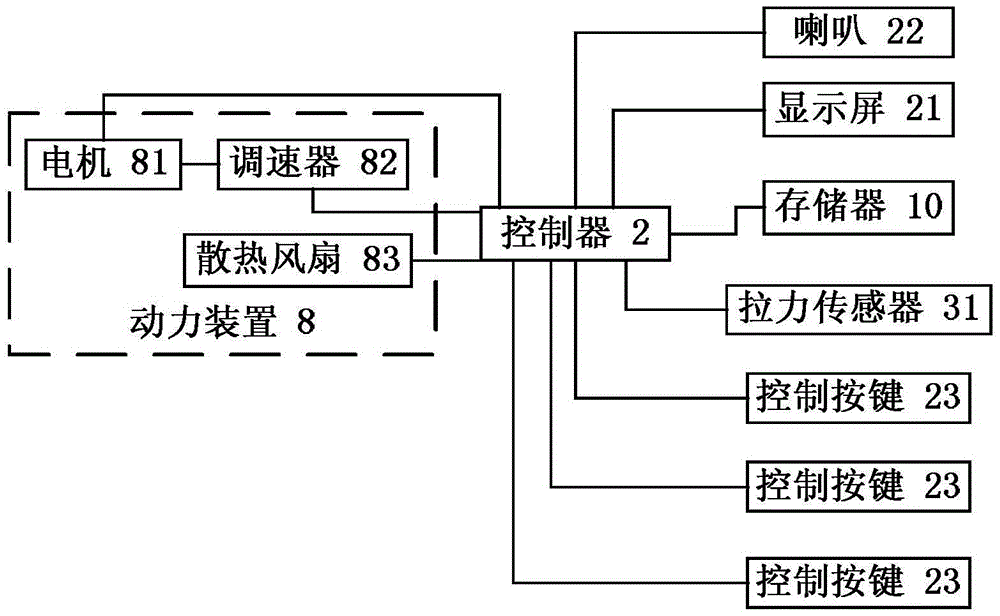

[0043] Such as figure 1 , figure 2The illustrated embodiment is a wire harness fatigue testing device, including a frame 1, a memory 10, a controller 2 arranged on the frame, a first wire harness fixing plate 3 extending longitudinally, and a 2 below the first wire harness fixing plate. A horizontal guide rail 4, a longitudinally extending second wire harness fixing plate 5 that is slidably connected to the two horizontal guide rails, a connecting rod 6, a horizontal turntable 7 located inside the two horizontal guide rails, and a power unit 8 connected to the horizontal turntable; one end of the connecting rod It is connected to one side of the second wiring harness fixing plate, and the other end of the connecting rod is connected to the edge of the horizontal turntable; the controller is provided with a display screen 21, a horn 22 and three control buttons 23. It also includes a horizontal rectangular frame 9 through which the first wire harness fixing plate is detachabl...

Embodiment 2

[0060] Embodiment 2 includes all structure and method parts of embodiment 1, such as figure 1 , image 3 As shown, the first wire harness fixing plate in embodiment 2 is provided with a tension sensor 31, and the tension sensor is connected to the second wire harness fixing plate through a test rope 32; the first wire harness fixing plate is detachably connected to the frame;

[0061] Step 90, debugging before testing

[0062] Step 901, the standard tension range is set in the memory; before pressing the start test button, the operator presses the debug button;

[0063] Step 902, the controller controls the horizontal turntable to rotate at a speed c through the power device, and the horizontal turntable drives the second wire harness fixing plate to reciprocate along the two horizontal guide rails through the connecting rod, and each of the first wire harness fixing plate and the second wire harness fixing plate A wire harness is stretched and bent repeatedly;

[0064] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com