Detection artificial load for movable electric vehicle charger

A technology for electric vehicles and simulated loads, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of being unable to meet the requirements of on-site mobile testing, bulky, etc., to facilitate mobile on-site testing and simplify the test process , the effect of reducing the number of switches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

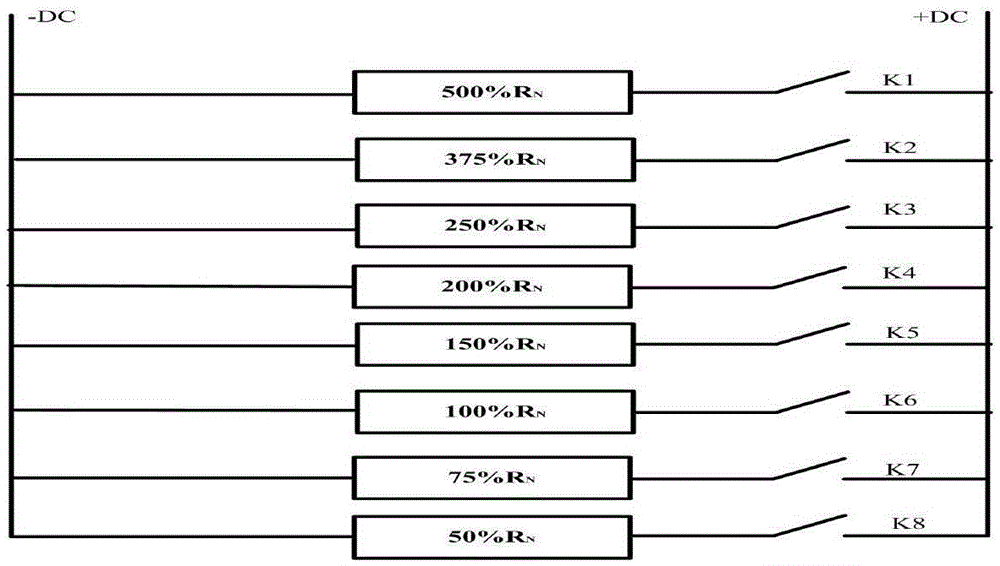

[0009] figure 1 Schematic diagram of simulated load wiring for mobile testing equipment for electric vehicle chargers, combined below figure 1 The present invention is introduced in detail.

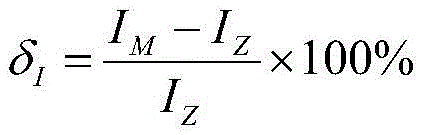

[0010] This simulated load is tested for the charger module. Electric vehicle charger safety performance test and output characteristic test include output current error test, output voltage error test, steady current accuracy test, voltage steady accuracy test, ripple coefficient test, voltage limiting function test and current limiting function test. Varistor test. The variable resistance test requires the output voltage of the charger to vary within the range of 50% to 100%, and the output current to vary within the range of 20% to 100%. In order to facilitate the on-site mobile detection of the charger and reduce the size of the equipment, it is proposed to take the two ends of the output voltage and current plus the three values in the middle for detection. There are 9 working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com