A Trial Spectrum Clipping Method to Realize Uniaxial and Triaxial Random Vibration Stress Equivalent

A random vibration and stress equivalent technology, applied in the field of mechanical vibration, can solve the problems of product damage, less data samples, high data cost, etc., to overcome the spectral envelope, simplify the process of data acquisition, and simplify the data acquisition process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Taking a vibration system as an example, the present invention will be further described in conjunction with the drawings and specific embodiments:

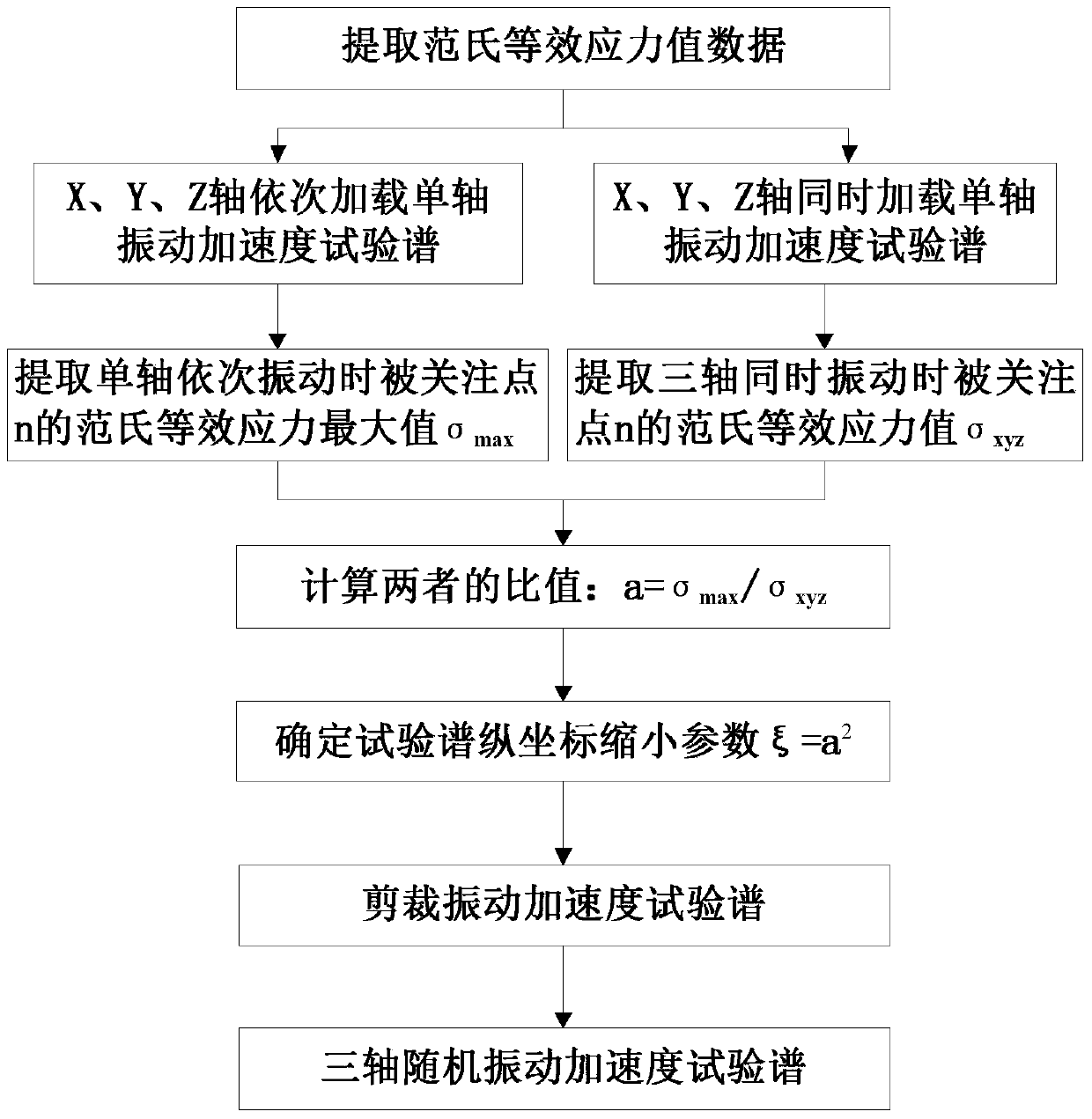

[0039] refer to figure 1 , the implementation steps of the present invention are as follows:

[0040] Step 1: Extract Fan's equivalent stress value data.

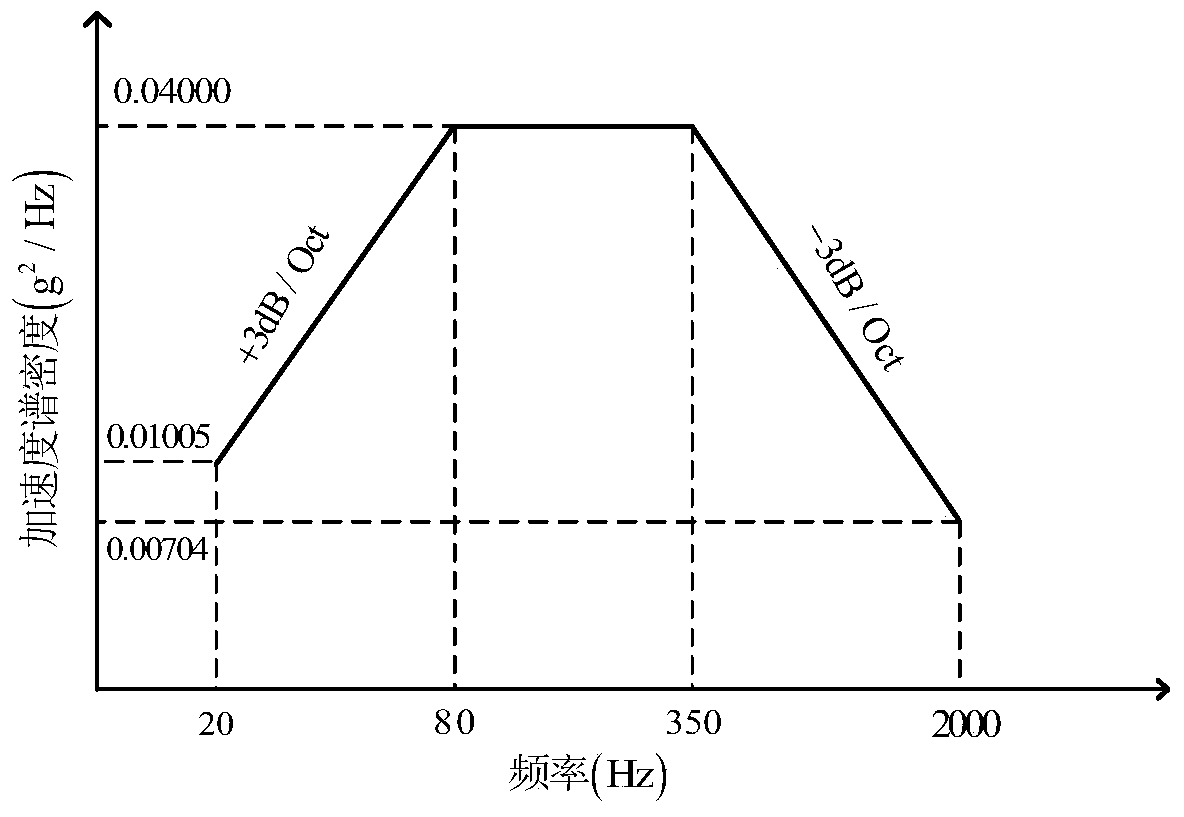

[0041] Such as figure 2 As shown, the test frequency band of the uniaxial vibration acceleration test spectrum of a vibration system specified in the GJB150A-2009 standard is 20Hz to 2000Hz, the slope of the rising spectrum is +3dB / Oct, the slope of the falling spectrum is -3dB / Oct, and the flat spectrum The spectral value is 0.04g 2 / Hz;

[0042] The finite element model of the vibration system is established in the finite element software Ansys Workbench, and the single axis is extracted and loaded sequentially in the X, Y, and Z directions figure 2 When the uniaxial vibration acceleration test spectrum is obtained, the Fann equivalent stress values of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com