Helical line slow-wave structure with asymmetrical metal loaded blocks

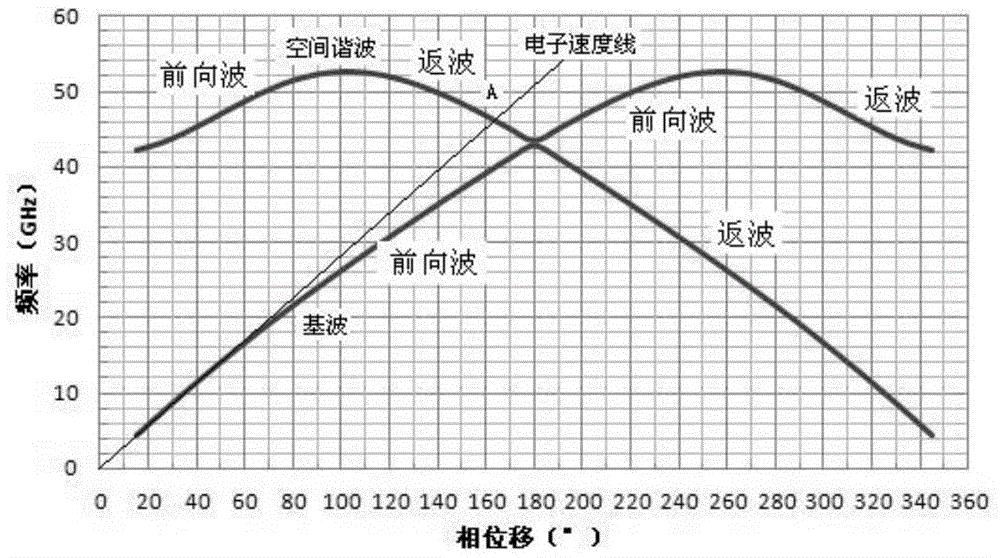

A slow-wave structure and metal-loaded technology, which is applied to the circuit components of the time-of-flight tube, can solve problems such as back-wave oscillations, and achieve the effects of improving performance stability, suppressing back-wave oscillations, and improving process consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

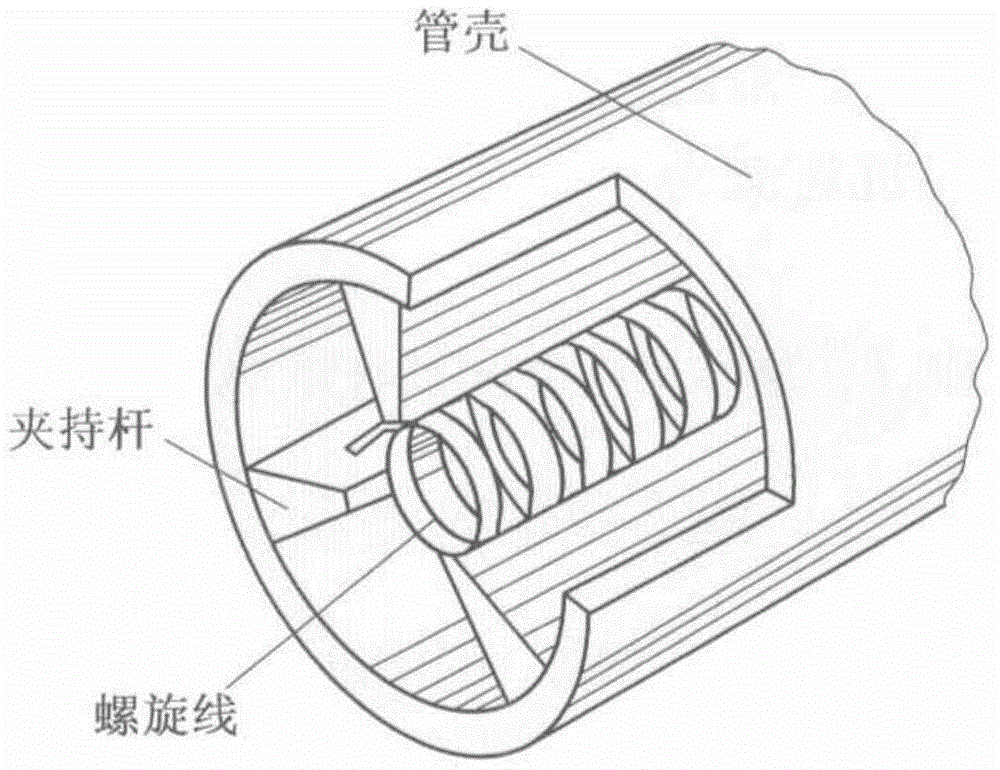

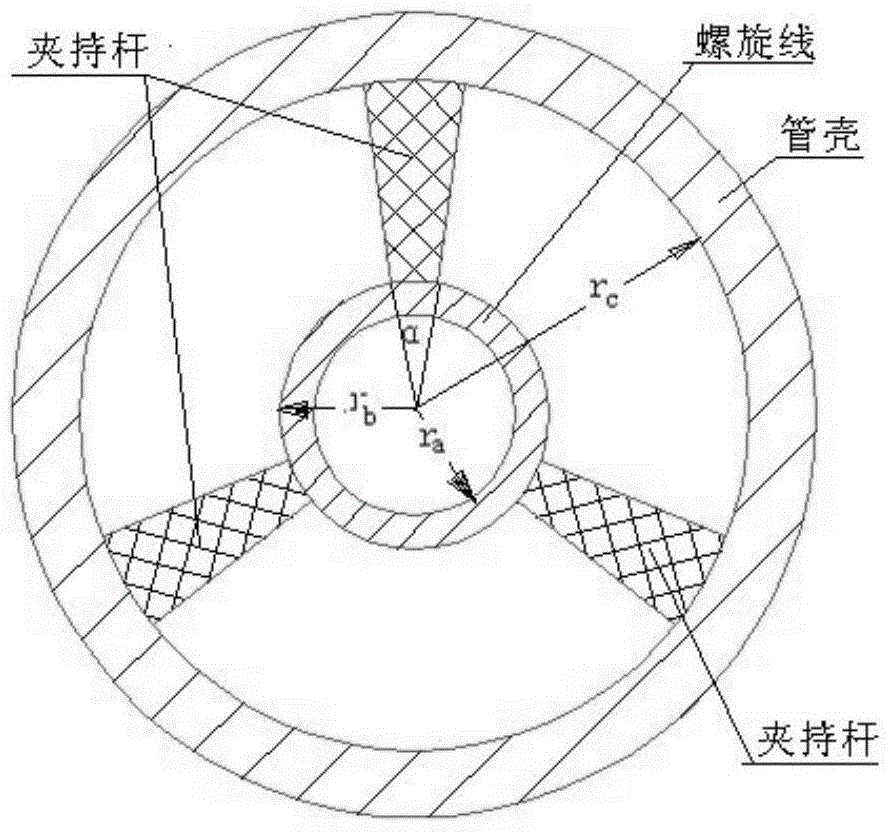

[0032] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0033] Due to the introduction of angular asymmetric metal loading, adjusting the distance between the metal loading block and the helix and the width of the loading block can effectively change the width of the forbidden band, thereby affecting the effect of suppressing the return wave oscillation. This distance shall be between the minimum distance that can ensure that no mechanical contact between the metal loading block and the helix occurs under any mechanical or thermal stress and 35% of the outer radius of the helix....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com