Large-air gap resonant linear induction motor

A linear induction motor, resonant technology, applied in electrical components, electromechanical devices, circuit devices, etc., can solve the problems of application limitations and low efficiency of linear induction motors, and achieve the effects of large induced current, large thrust and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

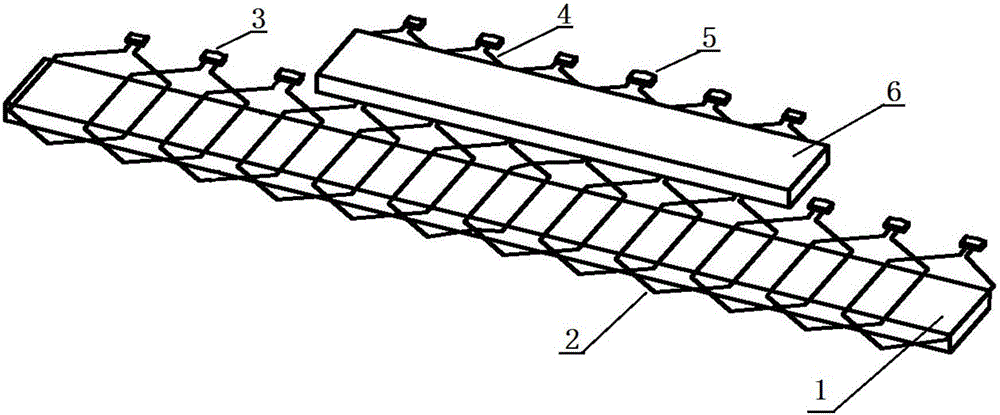

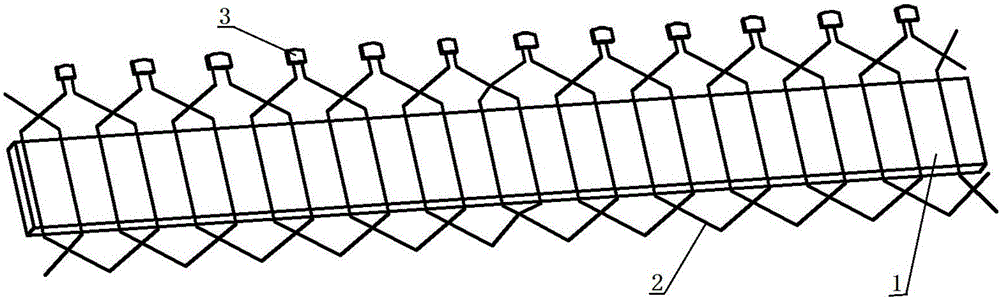

[0020] Shown by accompanying drawing .1, the specific embodiment of the present invention is:

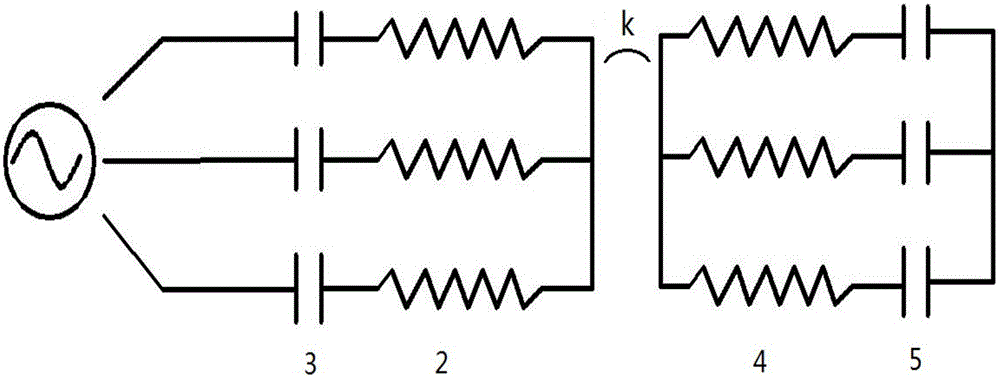

[0021] The primary three-phase symmetrical winding is wound on the primary iron core 1, and each phase winding is connected in series with the primary compensation capacitor 3 to make it work in a resonant state. The current of the primary winding 2 is provided by a three-phase high-frequency AC power supply or a power frequency inverter device. The primary winding 2 is wound by Litz wire, which can reduce the skin effect under high-frequency AC state. The structure and material of the secondary winding 4 are the same as those of the primary winding 2. It adopts a star or delta connection and is connected in series with the secondary compensation capacitor 5. Its resonant frequency is the same as that of the primary winding 2. At this time, the primary winding 2 and the secondary The primary winding 4 achieves strong magnetic coupling resonance under a large air gap, and the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com