Local bump epitaxy for improved contact by local silicon capping during trench silicide processing

A technology of contacts and epitaxial materials, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] As noted above, the present disclosure relates to finFET structures with low source / drain contact resistance and methods of fabrication thereof. Aspects of the present disclosure will now be described in detail with reference to the accompanying drawings. It should be noted that the same reference numerals refer to the same elements for different embodiments. The drawings are not necessarily drawn to scale. As used herein, ordinal numbers such as "first" and "second" are used only to distinguish similar elements, and different ordinal words may be used to refer to the same elements in the specification and / or claims.

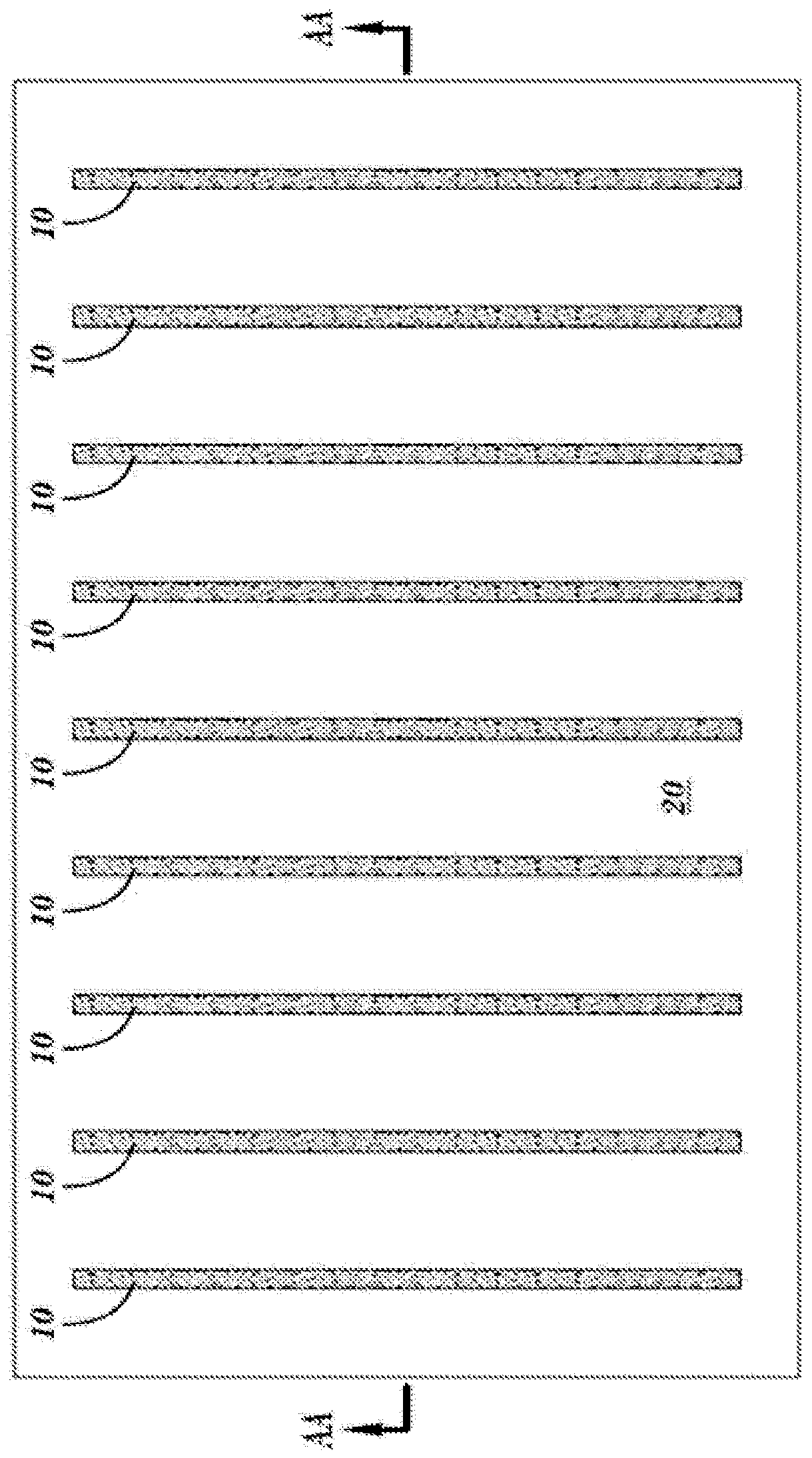

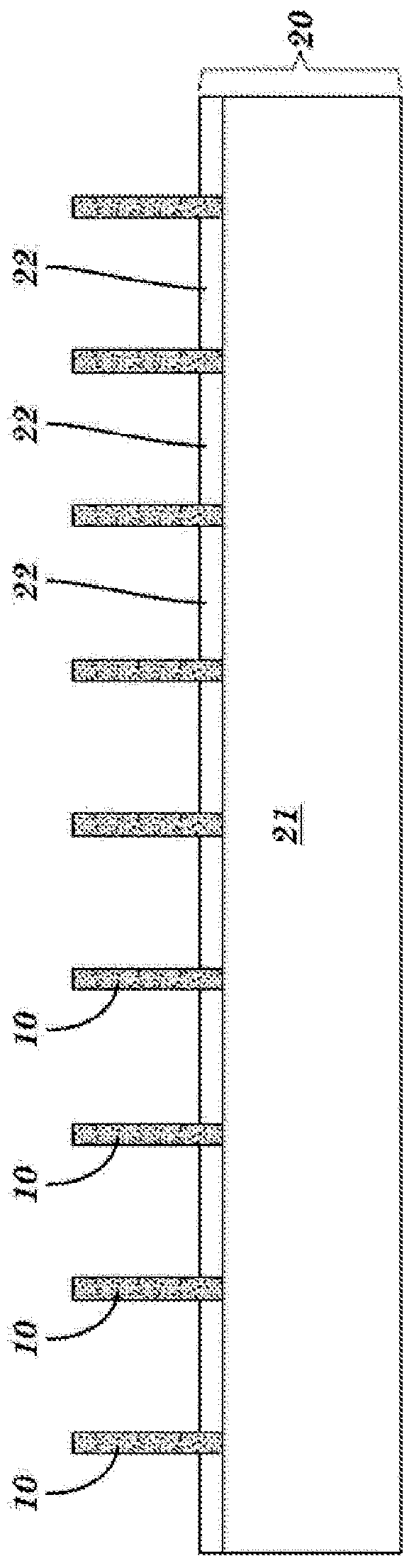

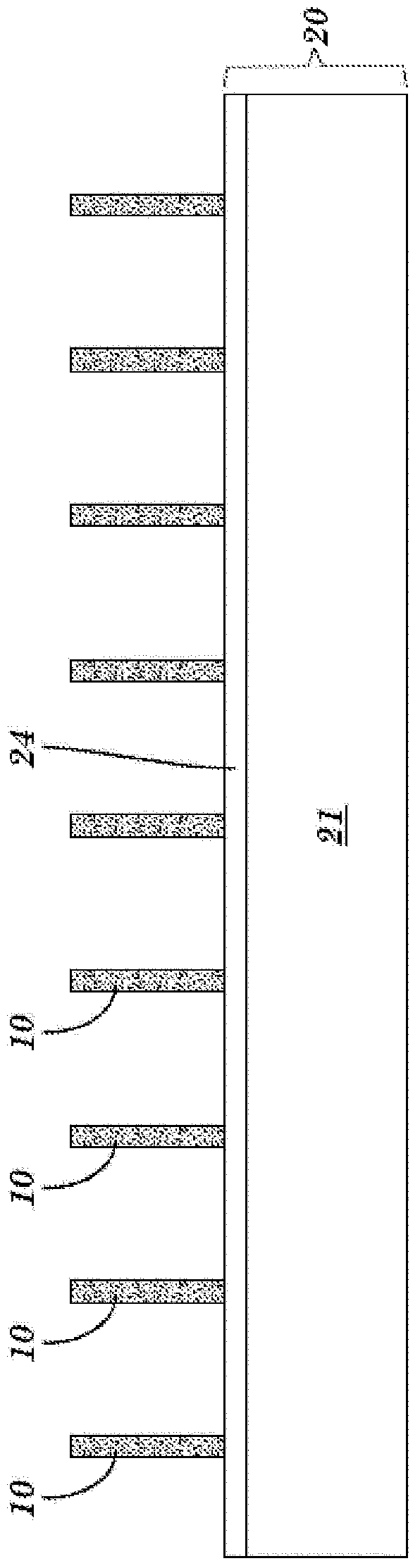

[0022] Figures 1A-1C An array of fins (10) formed on a substrate (20) constituting a preliminary structure for embodiments of the invention is illustrated. Such as Figure 1A As shown in , the fins 10 may have a uniform width and the array of fins may have a uniform pitch. In an embodiment, the width may be in the range of 4nm to 15nm, although small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com