Anti-floating filter plate of upward flow suspension filter material filter pool and preparation and installation method thereof

A technology of suspended filter material and floating filter plate, which is applied in separation methods, chemical instruments and methods, fixed filter element filters, etc., can solve the problems of losing the filtering effect and polluting the environment, and achieve cost saving, pouring quality improvement, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

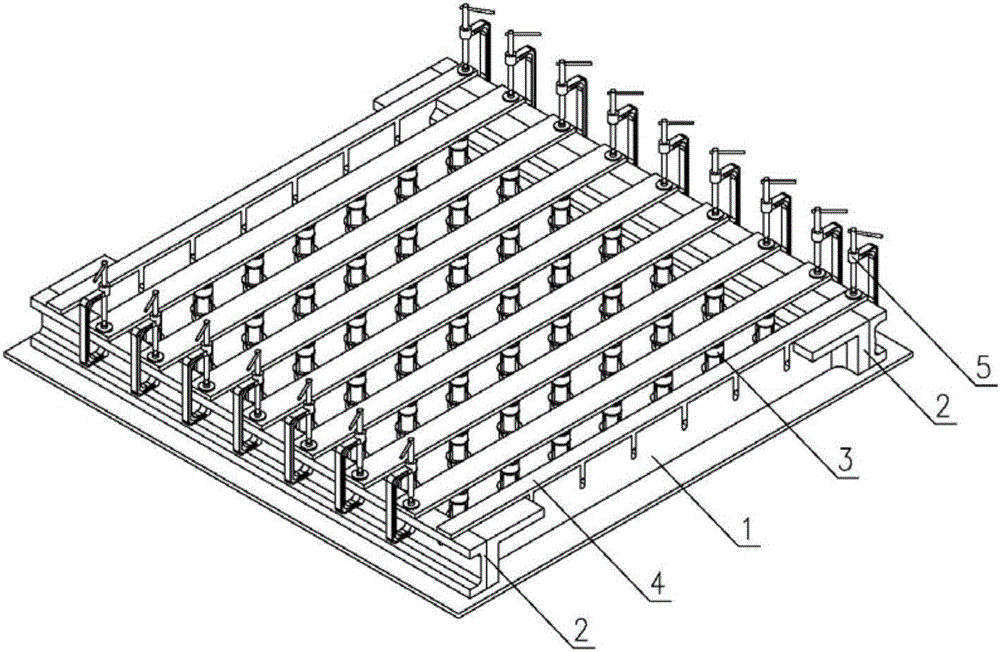

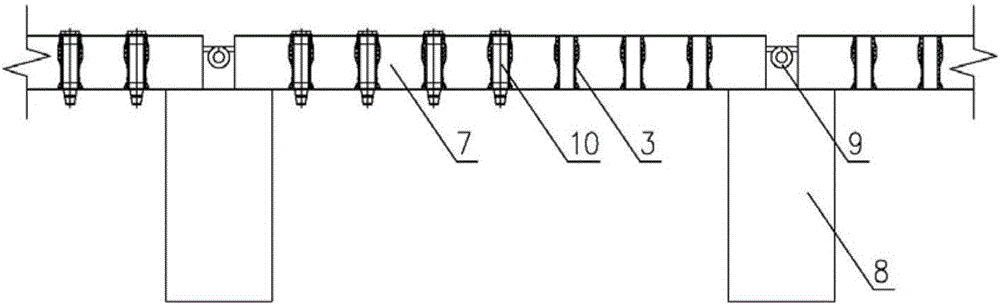

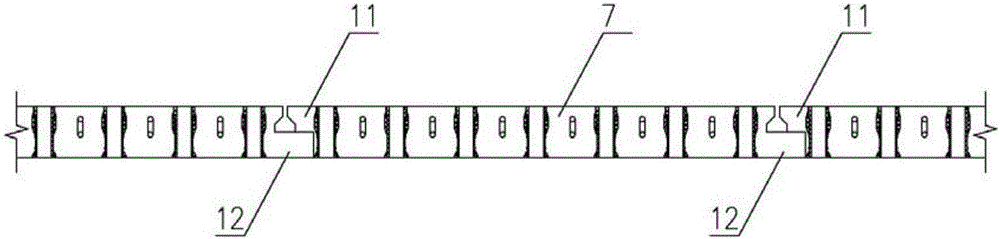

[0081] Specifically applied to a sewage treatment plant in Xi'an upward flow suspension filter filter. The daily treatment capacity of the sewage treatment plant is 150,000 tons / day. The filter tank is divided into 15 grids, each grid has a processing capacity of 10,000 tons / day, and each filter tank uses 50 anti-floating filter plates. The plane size of each anti-floating filter plate is 920mm×990mm, and the thickness is 100mm; the tongue and groove length is 35mm, and the thickness is 50mm; the weight of each anti-floating filter plate is about 450kg. There are 49 filter heads in total on each anti-floating filter plate. The concrete strength of the anti-floating filter plate is C25, the impermeability grade is P6, the frost resistance grade is F150, and HRB400 grade 10mm steel bars are used.

[0082] work process

[0083] During normal filtration, the water inlet control valve is opened, and the sewage flows through the filter material layer from bottom to top, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com