Parallel experiment equipment and parallel experiment method

A parallel experiment and equipment technology, applied in laboratory utensils, chemical instruments and methods, shells or chambers, etc., can solve the problems of money, time, and labor, and achieve less material, obvious rules, and simple equipment production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-7 The embodiments of the present invention will be further described in detail.

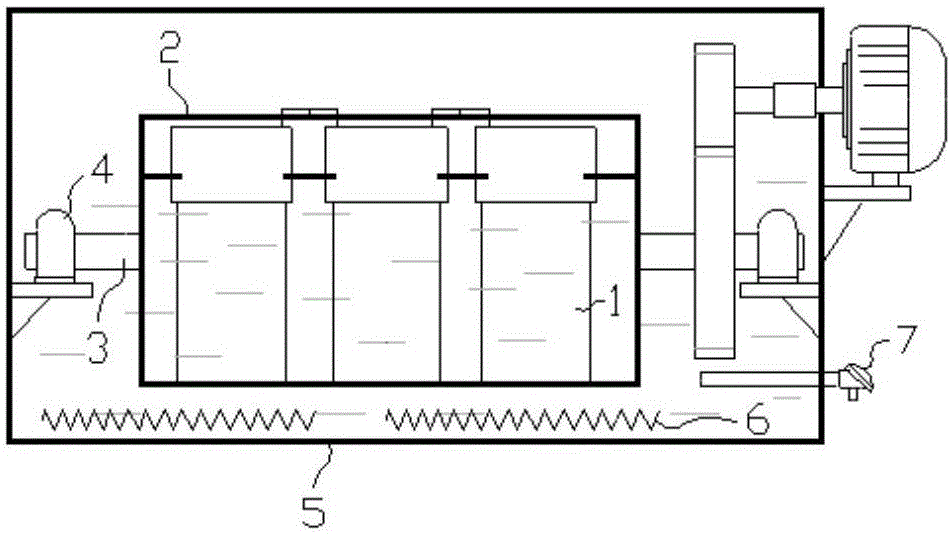

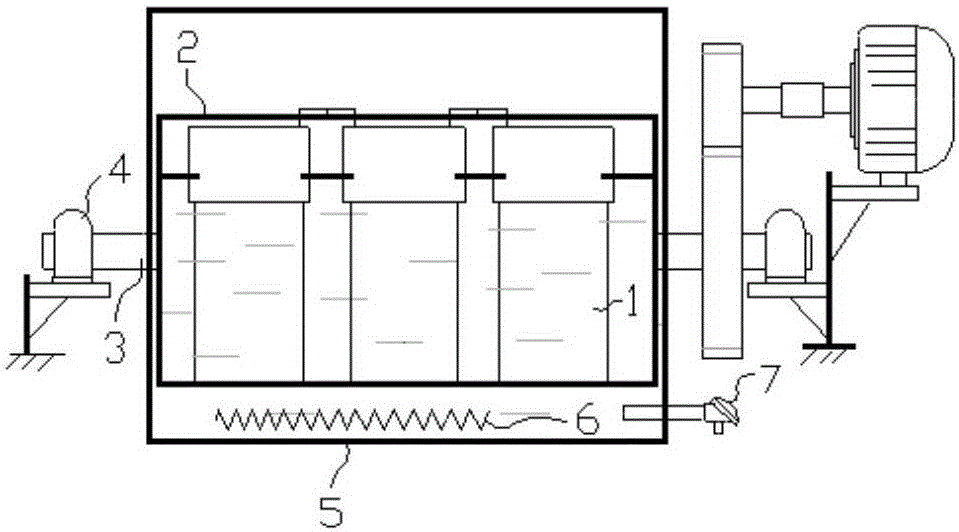

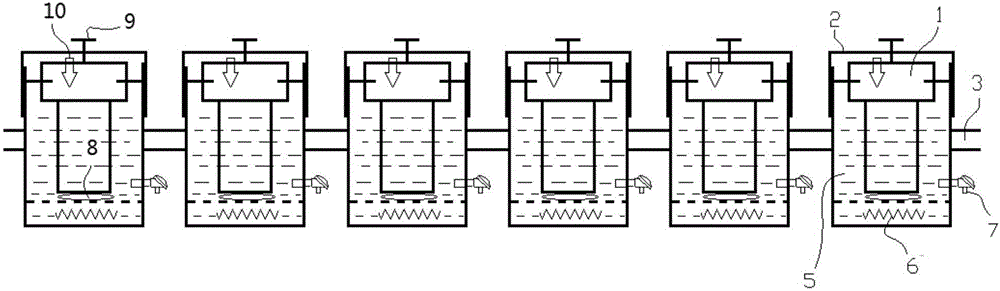

[0037] Such as figure 1 As shown, according to the first embodiment of the present invention, it is used to test the influence of different solid-liquid ratios and different acidities on the nickel leaching rate at a certain temperature for acid leaching of laterite nickel ore. The cover 1.2 of the steel cylindrical pressure-resistant container 1 is threadedly connected with the cylinder body 1.1 and sealed. During the experiment, the cover 1.2 of the container 1 is opened, and a certain amount of laterite nickel ore slurry, water and sulfuric acid are added to the container 1, and at the same time, the Several steel balls 1.3 for stirring the material, screw the container lid tightly to seal. The experimental cabin 2 can place and fix six sealed containers 1 at the same time. The rotating shaft 3 of the experimental cabin 2 is installed on the rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com