Material box with material scraping function

A function and material box technology, applied in the direction of electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve problems such as adverse effects on product quality, low production efficiency, and large safety hazards, and achieve strong practicability, clean process, and The effect of smooth work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

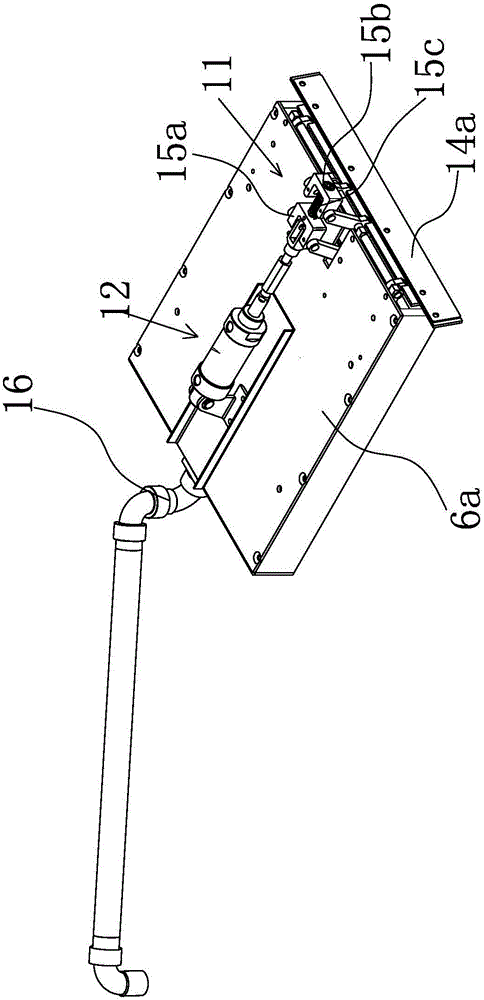

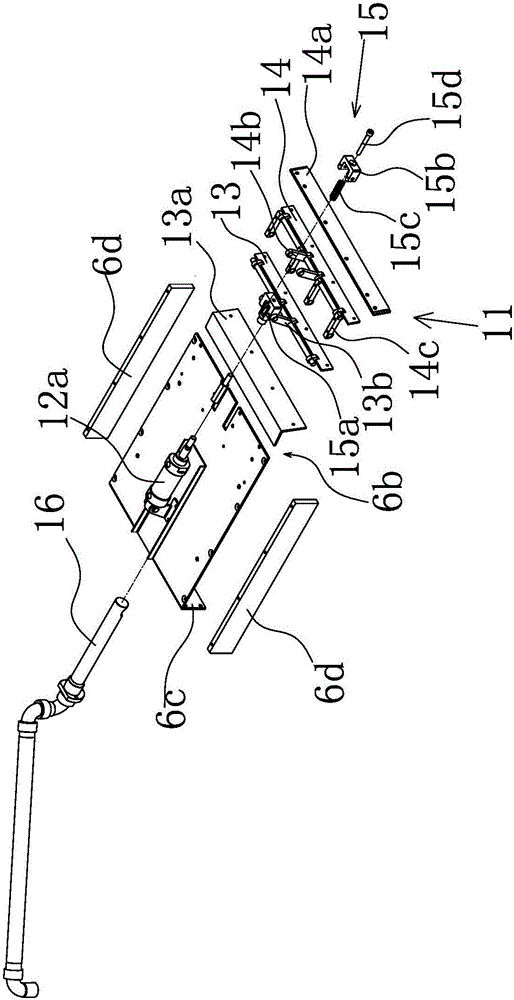

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Such as Figure 1-2 As shown, the material box with scraping function includes a box body 6a with an open bottom. The box body 6a is in the shape of a square box. The side of the box body 6a is provided with an opening 6b communicating with the inside of the box body 6a, and the opening 6b faces the box body 6a. In the direction of travel, the opening 6b is arranged on one side of the box body 6a, and the side plate 6c on the side opposite to the opening 6b is connected with a feed pipe 16, and the remaining two sides of the box body 6a are respectively provided with a wear-resistant side plate 6d. 6b is provided with a scraper assembly 11 for preventing the material in the box body 6a from leaking out of the box body 6a from the opening 6b and capable of scraping materials during the movement of the box body 6a. The scraper as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com