Test device for simulating laser cutting under marine environment

A technology of laser cutting and testing equipment, applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of optimizing laser parameter setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

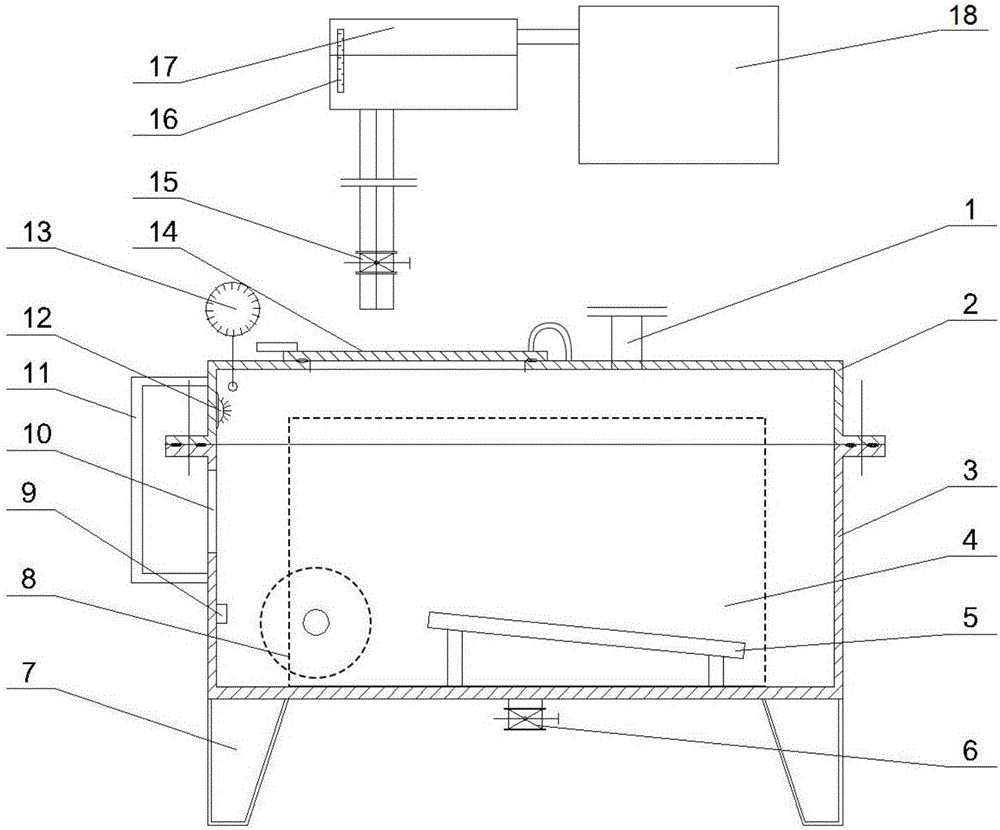

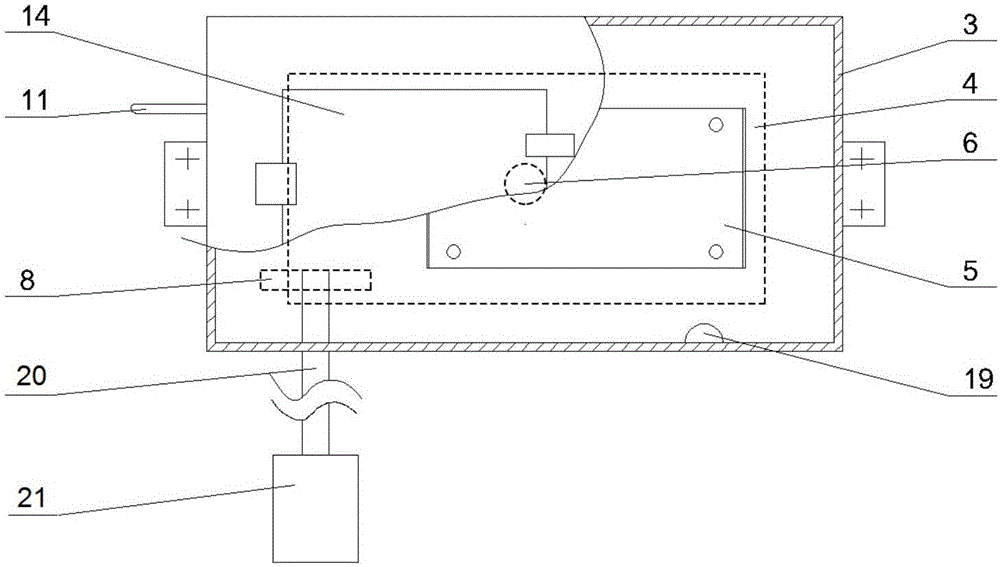

[0020] The laser cutting test device in a simulated marine environment includes a pressurized test box and a laser cutter 4 inside the test box. The cutting device can complete the cutting in the marine environment simulation system. In order to complete the cutting, an environmental parameter monitoring system and a control system are also required.

[0021] The laser cutting test device under the simulated marine environment includes: the bottom surface of the pressurized test box is fixed on the ground by the base 7 of four tripods. The middle part of the bottom surface under the pressurized test chamber is designed with drainage holes and drainage valves 6 .

[0022] A pressurized test chamber and a laser cutter 4 positioned inside the pressurized test chamber;

[0023] The bottom surface of the pressurized test chamber is designed with a drain valve 6;

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com