Mobile phone shell polishing robot

A mobile phone case and robot technology, applied in the direction of grinding/polishing equipment, grinding machines, grinding racks, etc., can solve the problems of high labor cost and low work efficiency, and achieve the effect of high degree of automation and novel structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described below in conjunction with specific embodiments.

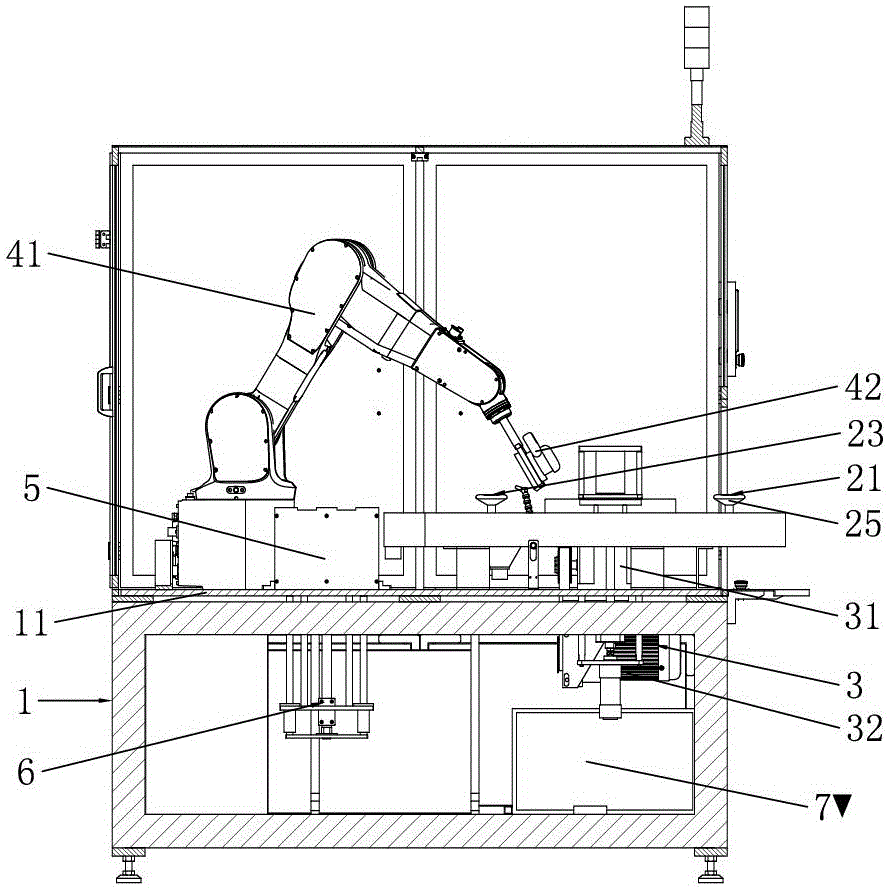

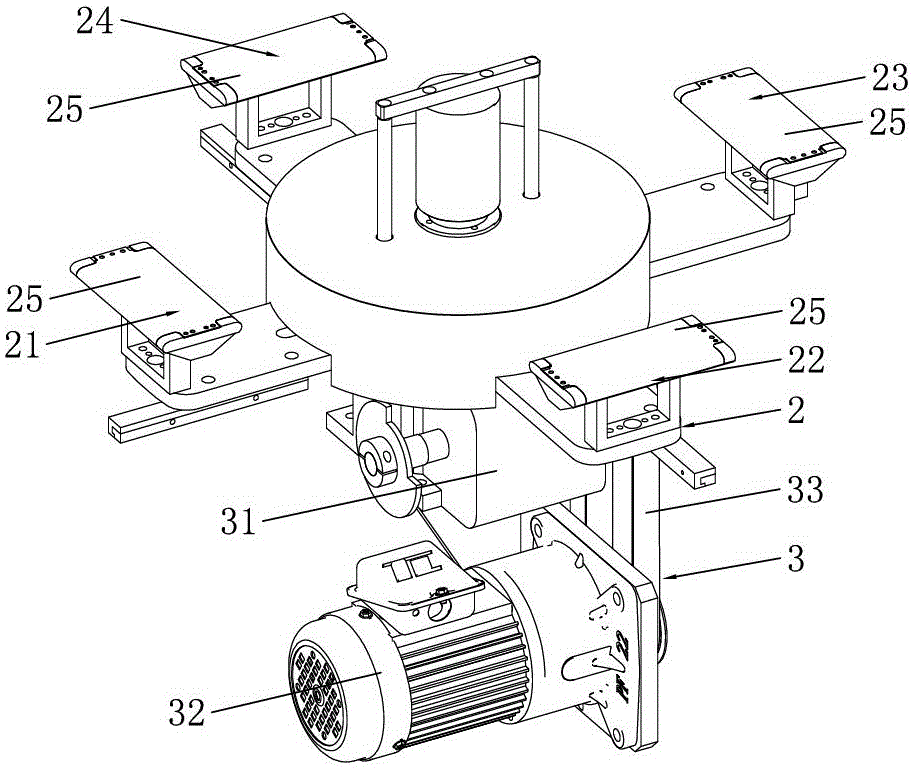

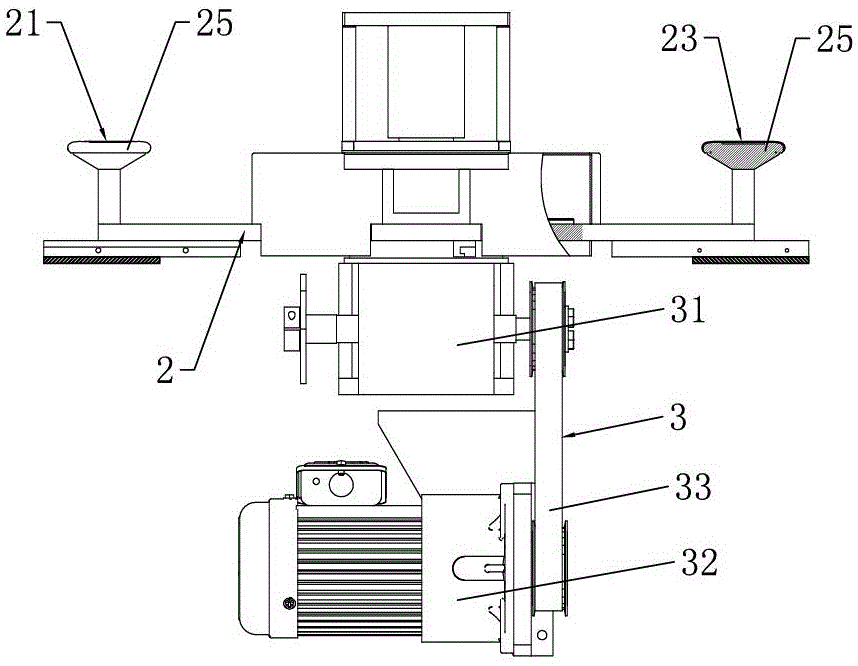

[0036] Such as Figure 1 to Figure 3 As shown, a mobile phone shell grinding and polishing robot includes a frame 1, the upper end of the frame 1 is equipped with a fixed support plate 11 arranged horizontally and horizontally, and the upper end side of the fixed support plate 11 can be installed relatively intermittently. A movable turntable 2 is provided, and the movable turntable 2 is provided with a circular uniformly spaced loading and unloading station 21, a front middle station 22, a grinding and polishing station 23, a rear middle station 24, and the loading and unloading of the movable turntable 2. The station 21, the front middle station 22, the grinding and polishing station 23, and the rear middle station 24 are respectively equipped with mobile phone case positioning jigs 25.

[0037] Further, the frame 1 is equipped with a turntable drive mechanism 3 corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com