A Vapor Deposition Thin Coating Curing Tooling

A vapor deposition, thin coating technology, used in workpiece clamping devices, measuring devices, manufacturing tools, etc., can solve the problem of difficult to obtain clamping preload, achieve simple structure, accurate position, and reduce displacement deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will be further described below in conjunction with the accompanying drawings.

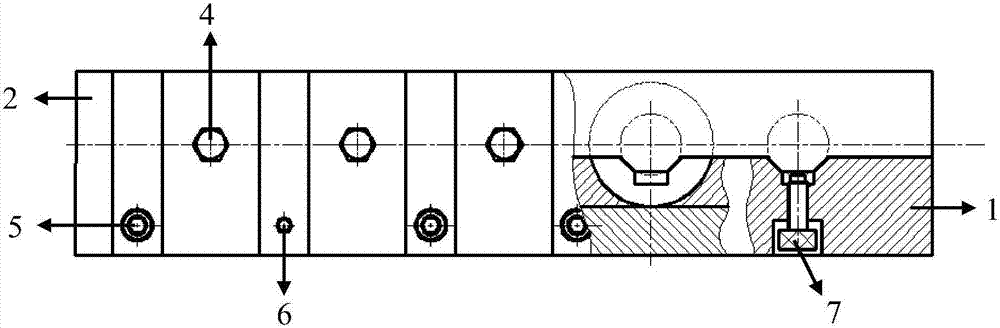

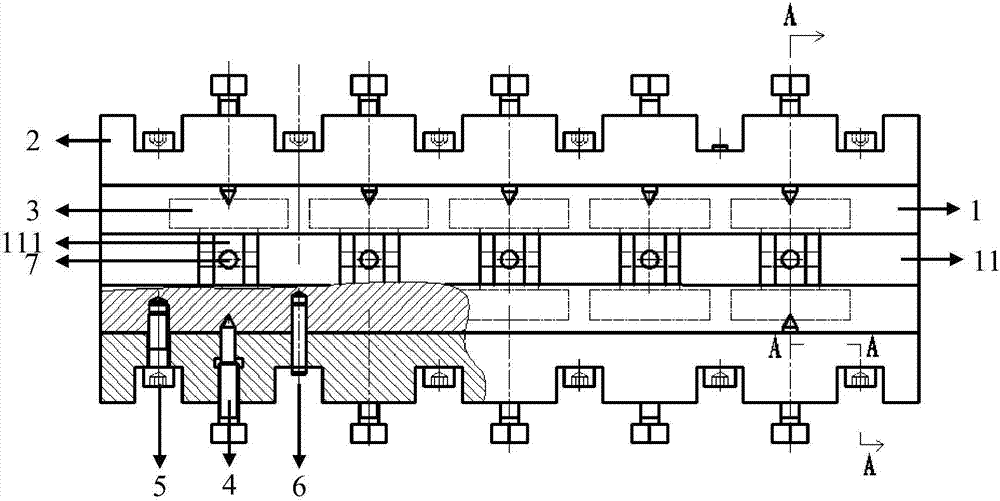

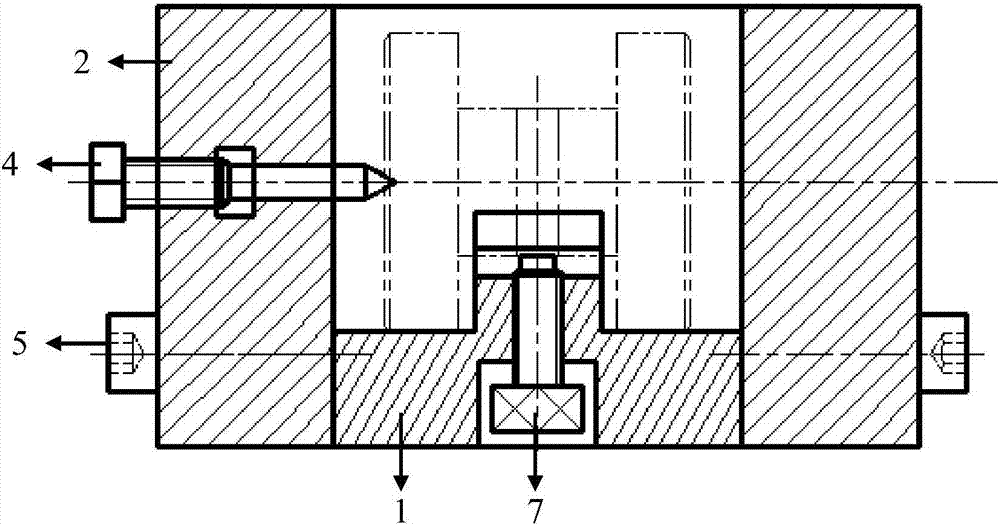

[0031] An embodiment of the inventive structure of the present invention is as Figure 1-3 As shown, it includes a seat plate 1, a side plate 2 and a loading block 3; the side plate 2 is fixed on both sides of the seat plate 1; the center of the seat plate 1 is provided with a support rib 11 parallel to the side plate 2, Several grooves 111 are evenly distributed on the support rib 11; the loading block 3 is in the shape of a stepped shaft, symmetrical in pairs with respect to the support rib 11 and uniformly distributed along the extending direction of the support rib 11; the loading block 3 The small end of the loading block 3 is located in the groove 111 of the supporting rib 11 and is limited by the groove 111, and the large end of the loading block 3 is located on any upper surface of the seat plate 1 on both sides of the supporting rib 11 And be positioned by this upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com