Silicon ingot cutting equipment and silicon ingot cutting method

A silicon ingot and equipment technology, applied in the field of silicon ingot cutting equipment and silicon ingot cutting field, can solve the problems of uneven wear, unbalanced tension, cutting line damage, etc., to extend service life, improve production efficiency, high The effect of balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

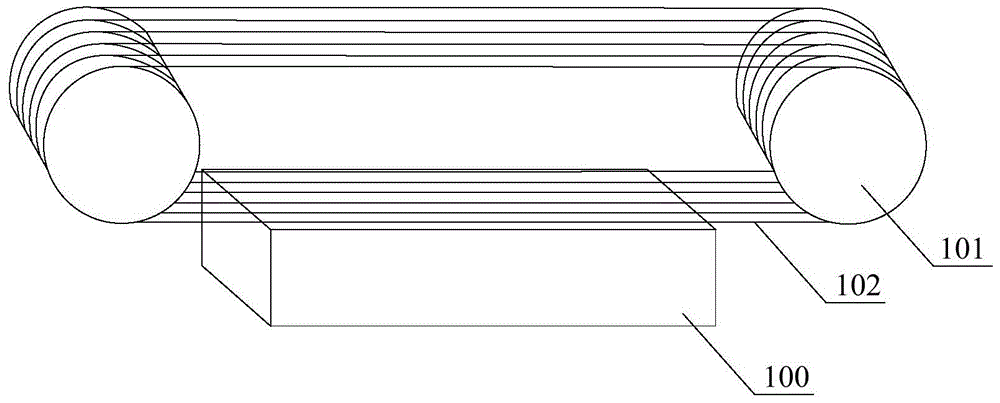

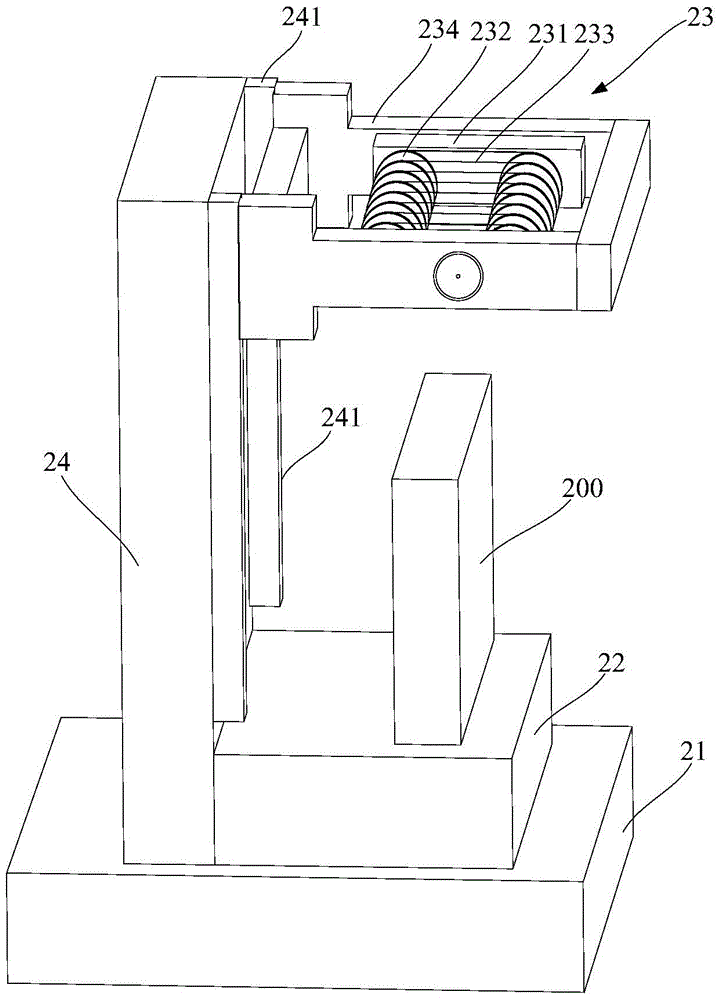

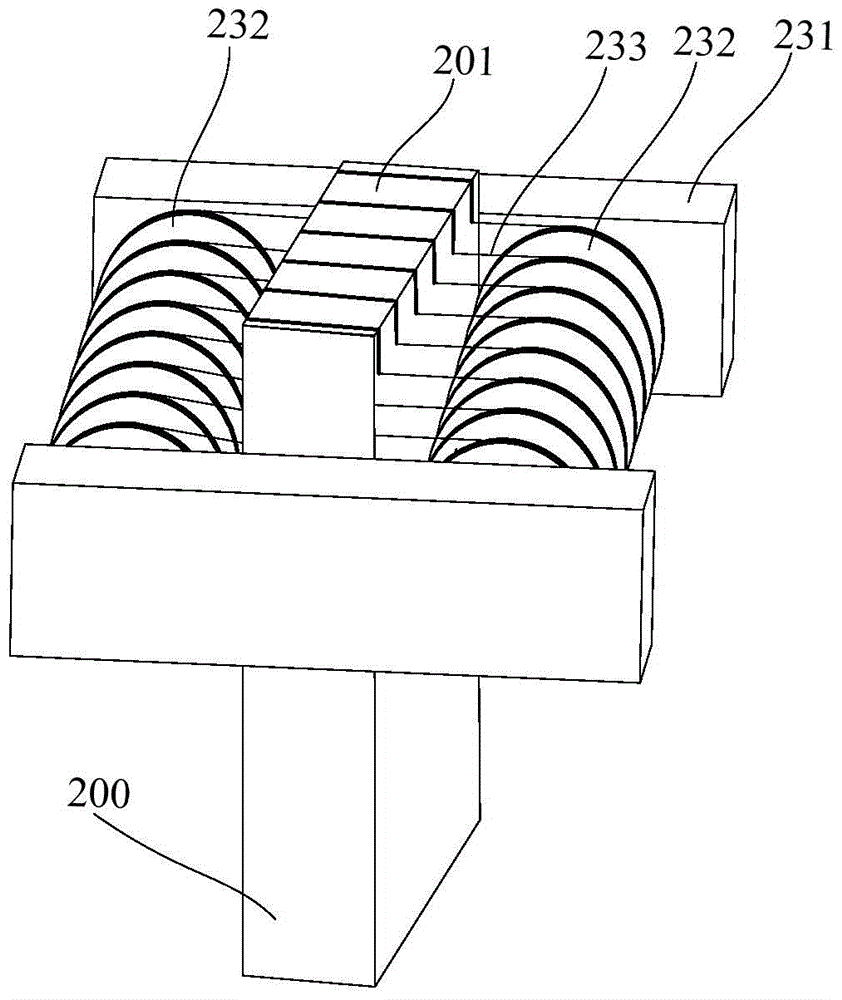

[0052] In the prior art, silicon ingots are generally placed and cut in a tiled manner. In this way, the effective cutting line segment for correspondingly cutting silicon ingots in the cutting line above the silicon ingots is relatively long. During the cutting process, The effective line segment will be blocked by the silicon ingot and will be stretched, resulting in unbalanced tension, affecting the cutting line and the cutting quality of the silicon ingot. In view of this, the present invention provides a new silicon ingot squaring method and silicon ingot squaring equipment, which realizes that the cutting line enters from the narrow side with a smaller width in the silicon ingot for cutting, so that the cutting line has a higher width during the cutting process. The balance can not only cut the line extension, but also ensure the precision and reliability of silicon ingot cutting, and improve the cutting quality of silicon ingots.

[0053] Embodiments of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com