Mold locking oil cylinder structure

A technology of clamping oil cylinder and oil channel, which is applied in the field of mold clamping cylinder structure, can solve the problems of increased energy consumption, slow hydraulic oil circulation speed, low oil flow, etc., achieve reliable and accurate work, increase work reliability, and improve The effect of cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

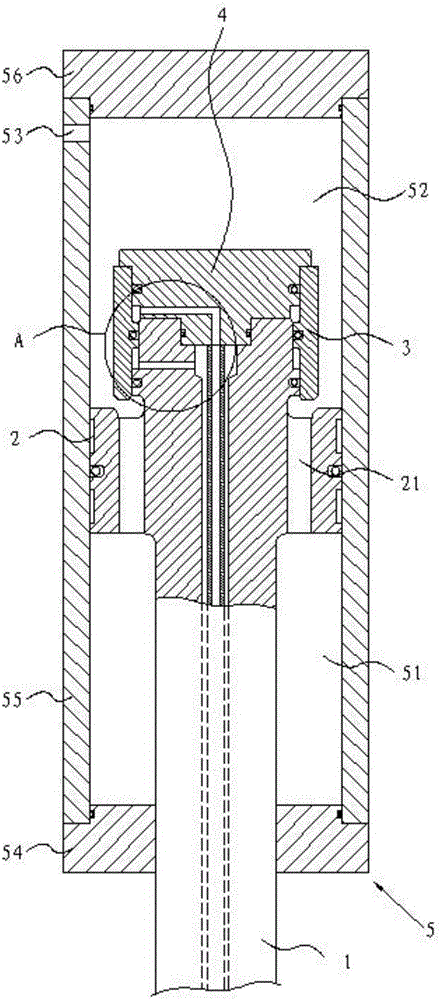

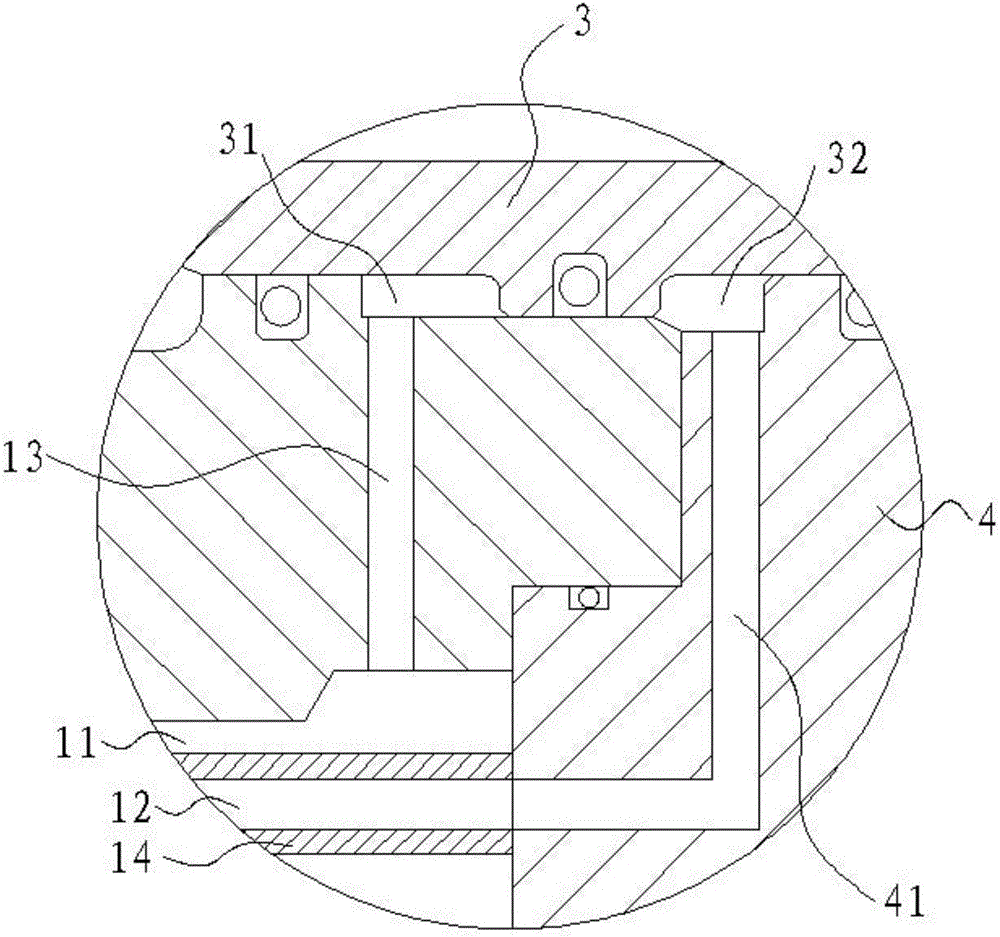

[0015] refer to figure 1 with figure 2 , a clamping cylinder structure of the present invention, including a piston rod 1, a piston 2, a valve core 3, a valve cover 4, and a cylinder body 5. Wherein, the cylinder block 5 comprises a cylinder barrel 54, a front end cover 55 and a rear end cover 56, the front end cover 55 and the rear end cover 56 are respectively installed at the two ends of the cylinder barrel 54, and can be connected with the cylinder barrel 54 through bolts or buckles. Disconnect the connection.

[0016] One end of the piston rod 1 is integrally formed with the piston 2, and the other end passes through the front end cover 55 so as to be connected with the injection molding machine. Two oil chambers 52, the first oil chamber 51 and the second oil chamber 52 are separated by the piston 2 and are respectively located on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com