Linear extension type sucker gripper mechanism

A telescopic and suction cup technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems that have not been thought about in a deeper level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing:

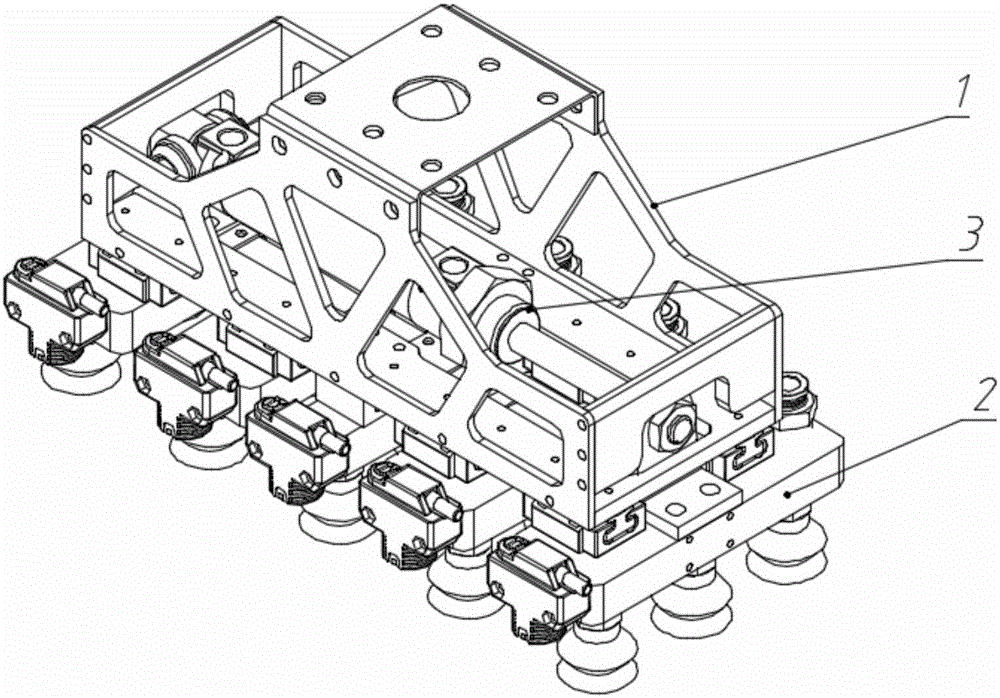

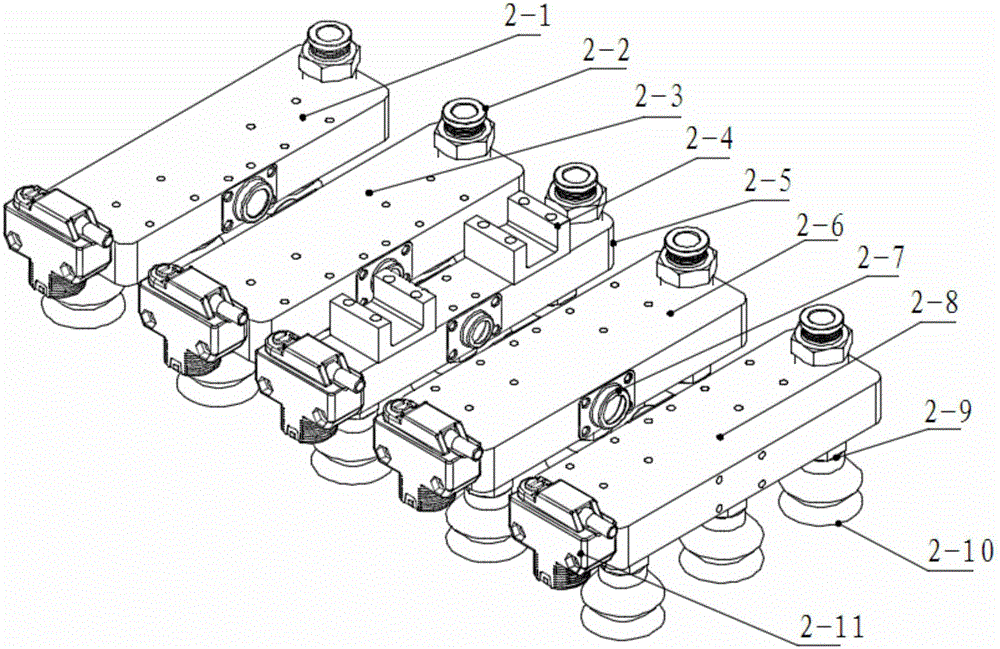

[0017] Such as figure 1 As shown, the present invention is composed of a grip frame assembly 1, a grip assembly 2, and a grip power assembly 3, and is characterized in that the four sucker bottom plates of the grip assembly 2 are fixed on the sliders 1-6 of the grip frame assembly 2 Above, the middle suction cup bottom plate 2-5 of the gripper assembly 2 is fixed on the guide rail mounting plate 1-4 of the gripper frame assembly 1, and the two ends of the cylinder 3-1 of the power assembly 3 are passed through the connecting piece (3-2, 3-5 ) is fixed on the suction cup base plate of the head and tail of the gripper assembly 2.

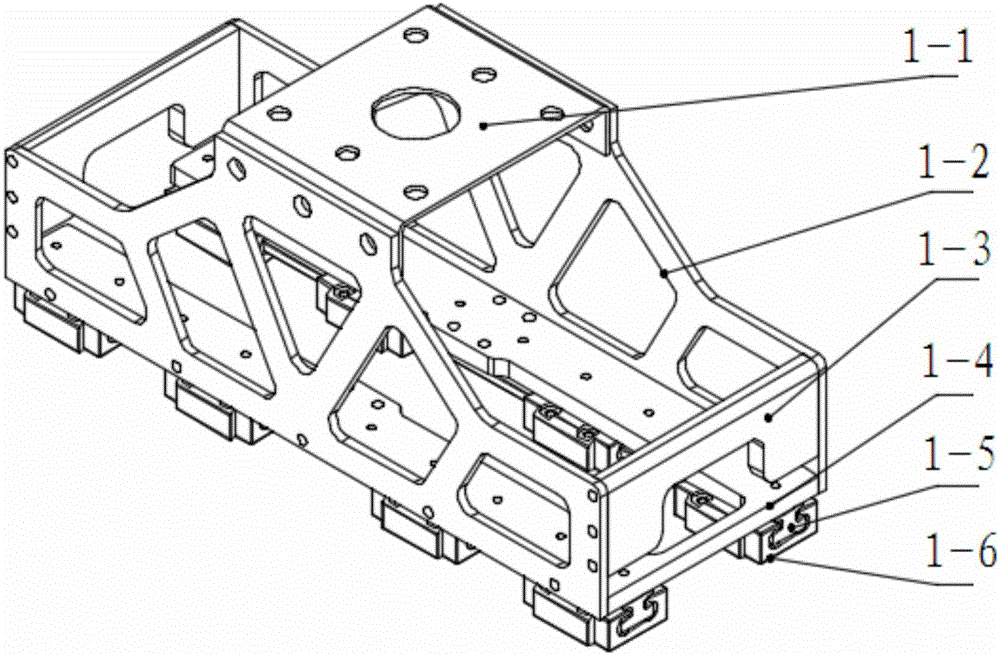

[0018] Such as figure 1 , figure 2 As shown, the grip frame assembly 1 of the present invention consists of an upper flange 1-1, two side plates 1-2, two end plates 1-3, a guide rail mounting plate 1-4, two guide rails 1-5, eight Composed of slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com