A filling high-level distributor

A distributor and high-position technology, which is applied in the field of filling high-position distributors, can solve problems such as low filling accuracy, different pressures, and gas escaping, and achieve the goal of improving filling accuracy, filling efficiency, and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

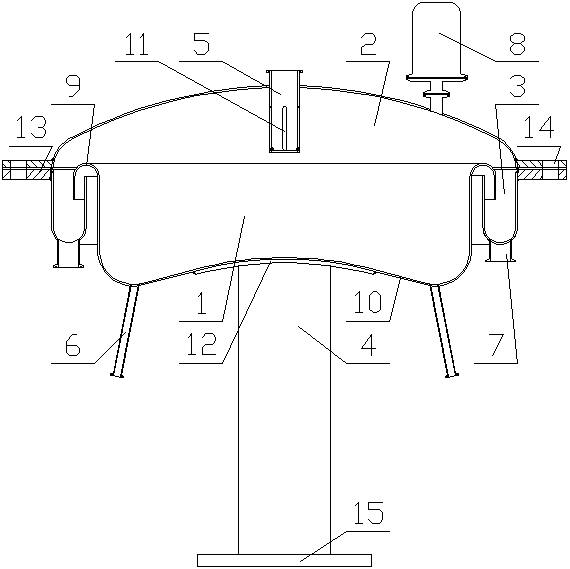

[0030] Such as figure 1As shown, the present invention comprises a bottom bucket 1, the top coaxial cover of the bottom bucket 1 is provided with a bung 2, and a plurality of filling pipes 6 are distributed on the bottom 10 edge of the bottom bucket 1, and the bung 2 A liquid inlet pipe 5 is provided, and the bung 2 is fixed to the liquid storage device through the liquid inlet pipe 5. The bottom 10 of the bottom bucket 1 is rotatably connected to the base 15 by rotating the vertical shaft 4. The diameter of the bung 2 is larger than The diameter of the bottom bucket 1, the bottom edge of the bucket cover 2 is fixed with an overflow tank 3, the overflow tank 3 is an annular structure, and the overflow tank 3 is placed on the top of the bottom bucket 1, the bucket of the bottom bucket 1 The mouth is provided with a flanging 9 outward, and the outer edge of the flanging 9 is located in the notch range of the overflow tank 3, and the filling pipe 6 is provided with a valve; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com